Method and system for manufacturing component by using shadow mask technological line

A production line and technical technology, applied in semiconductor/solid-state device manufacturing, electrical components, ion implantation plating, etc., can solve problems such as inability to manufacture microelectronic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

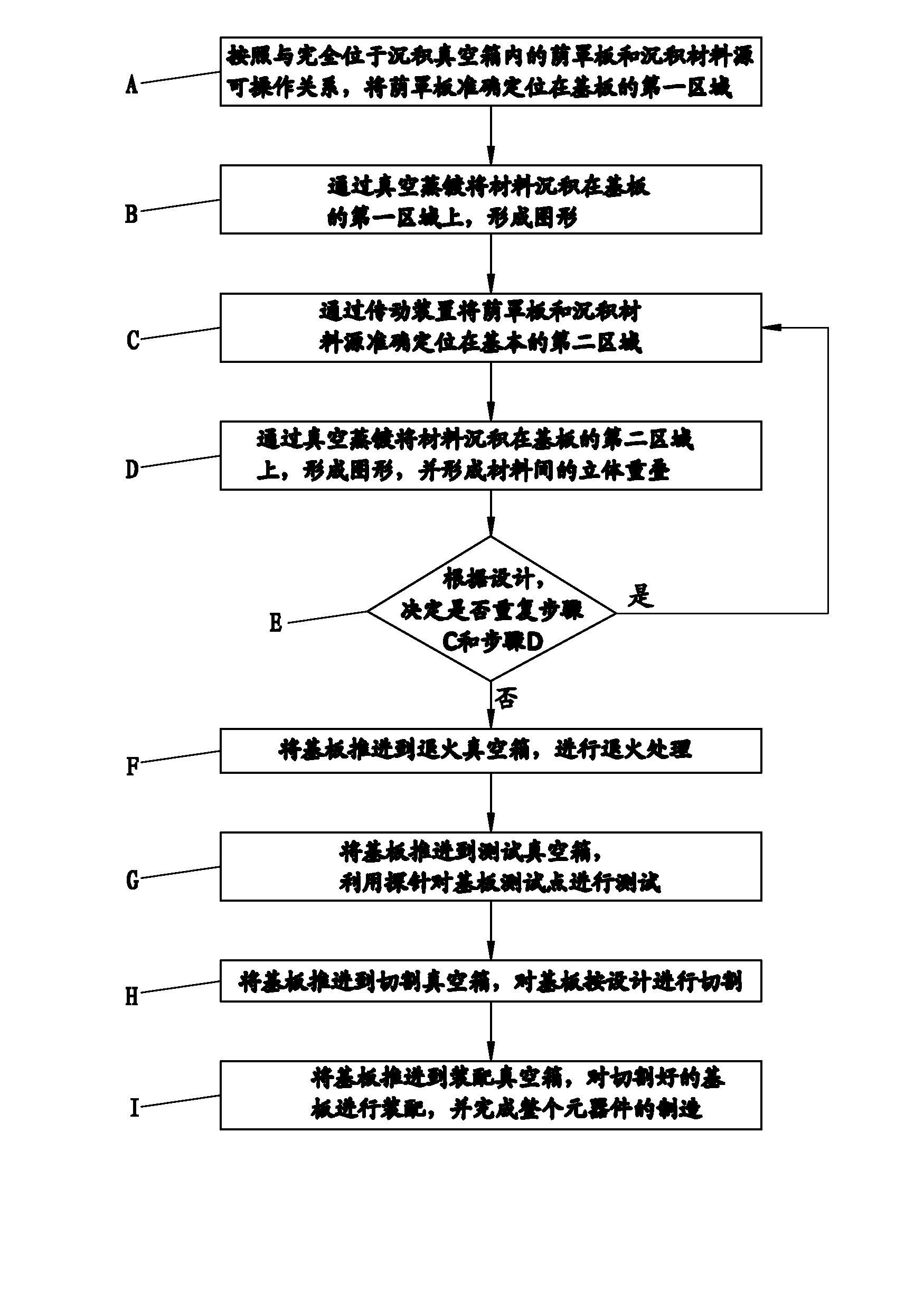

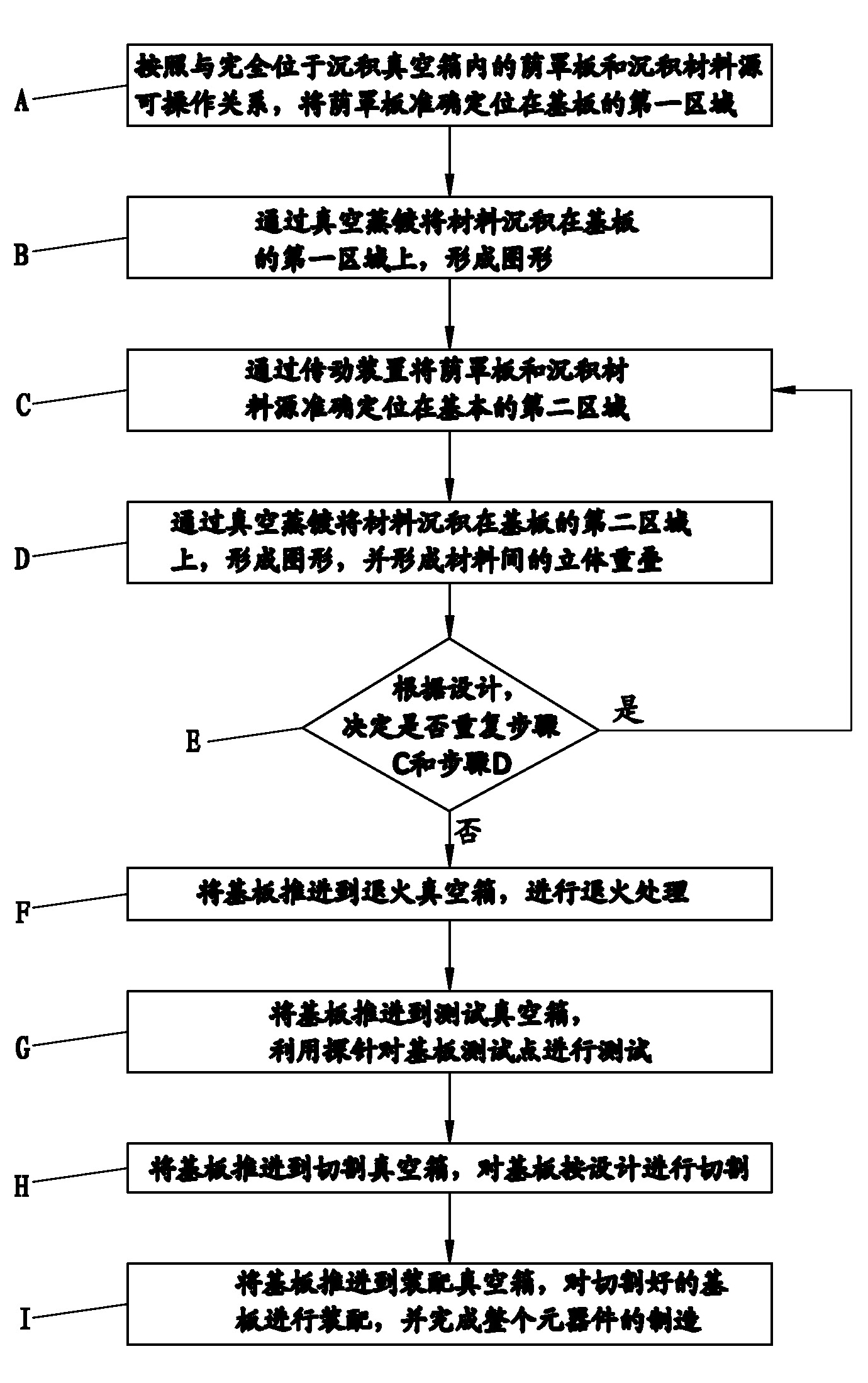

[0037] like figure 1 As shown, what it shows is a method for manufacturing devices using a shadow mask technology production line of the present invention, which includes the following steps:

[0038] A. accurately positioning the shadow mask on the first region of the substrate in operable relationship to the shadow mask and the source of deposition material positioned entirely within the deposition chamber;

[0039] B. Depositing the material on the first region of the substrate by vacuum evaporation to form a pattern;

[0040] C. Accurately position the shadow mask and the deposition material source in the basic second area through the transmission device; specifically, it can choose the way of moving the substrate or the way of moving the shadow mask to realize the positioning of the second area; When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com