Probiotic chewing gum method of manufacture

A technology of probiotics and chewing gum, which is applied in the production of strip, sandwich or coated chewing gum containing probiotics, the production of chewing gum containing probiotics, the process and mechanism of chewing gum, and the process of producing double-layer chewing gum, which can solve the problem of death, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

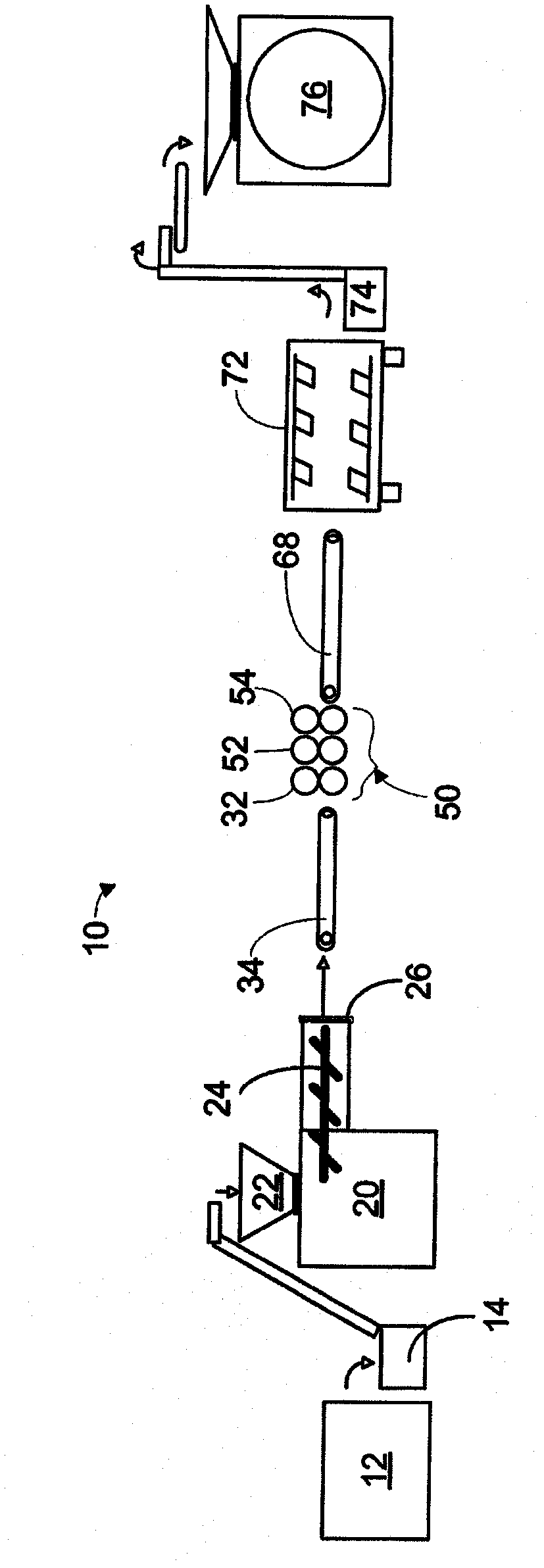

Method used

Image

Examples

Embodiment 1

[0066] Example 1: Extrusion of various extenders with various packages Determination of Viability of Probiotics in Chewing Gum

[0067] Seven chewing gum compositions were prepared by mixing the various components at a temperature of about 55°C. The components of the chewing gum and the content percentage of each component are shown in Table 1 below. The probiotic premix contains sorbitol and Lactobacillus plantarum 299v at a mass ratio of 9:1.

[0068] Component (%)

[0069] Table 1: Content percentages by weight of the various components of the chewing gum tested in Example 1

[0070] With "0" as the start of mixing, the various components were added to the mixer after the time periods shown in Table 2. Mixing was complete after 18 minutes.

[0071] components

[0072] Gum base

[0073] Table 2: Time points for addition of chewing gum components

[0074] A portion of Batch 1 probiotic gum was placed in a bottle containing desiccant and a...

Embodiment 2

[0081] Example 2: Preparation of extruded chewing gum containing probiotics

[0082] Three chewing gum batches containing probiotics were mixed, each weighing approximately 485 kg. Batch 1 contains pass 5.0 x 10 6 Theoretical initial load of CFU / serving added probiotics. Batch 2 contains pass 5.0 x 10 7 Theoretical initial load of CFU / serving added probiotics. Batch 3 contains pass 1.0 x 10 8 Theoretical initial load of CFU / serving added probiotics.

[0083] Three batches contained a probiotic premix of α-sorbitol and the probiotic Lactobacillus plantarum 299v (Probi AB, Lund, Sweden) in a 9:1 ratio. Adding sorbitol to probiotics helps to increase the volume of the probiotics for addition to the batch mixer and also to dry out probiotics that have been previously refrigerated.

[0084] The batch was mixed by first adding the gum base to the batch mixer. Then, add the extender or polyol to the mixer after 6 minutes. After another 1 minute, add the peppermint oil. Aft...

Embodiment 3

[0089] Example 3: Determination of the effect of mixing time on the viability of probiotics

[0090] Two batches of compressed chewing gum containing probiotics were prepared and different mixing times were used for each batch. In a first test, four different formulations shown in Table 7 were prepared. A portion of each formulation was placed in different types of packaging including blister packs, bottles with desiccant in bottles, bottles without any desiccant, and tubes.

[0091]

[0092] Table 7: Formulations produced in the first test

[0093]Formulations in Table 7 were prepared starting from the preparation of the probiotic premix. Mixing was performed using a low shear tumbler mixer (L.B. Bohle D-59320, model LM40) placed in a humidity controlled room. Xylitol and Lactobacillus plantarum 299v (Probi AB, lund, Sweden) were used in the premix in a weight ratio of 90:10. A masterbatch batch of liquid flavor, All-In-Gum SF (obtained from CAFOSA GUM S.A., Calavria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com