Liquid dairy product with edible colloidal particles

A technology for edible colloids and dairy products, applied in dairy products, milk preparations, applications, etc., can solve problems such as defects in taste and weak stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

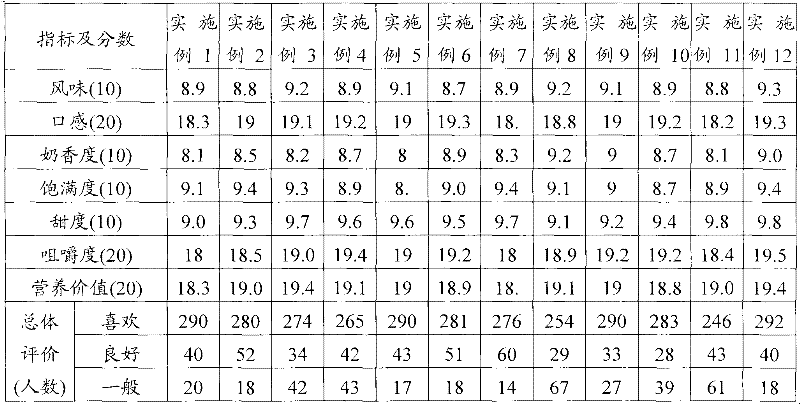

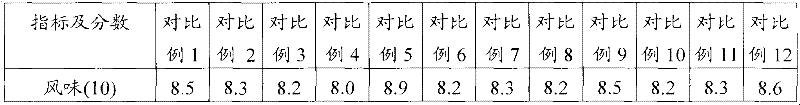

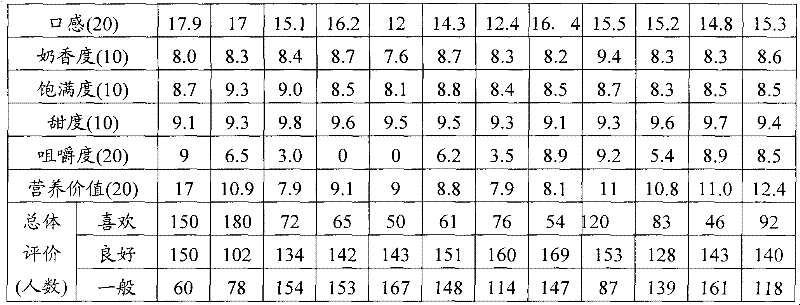

Examples

Embodiment 1

[0062] Embodiment 1 red bean grain modulation milk

[0063] Raw material standard:

[0064] Milk: protein ≥ 2.95%, fat ≥ 3.0%, non-fat milk solids ≥ 8.5%

[0065] White granulated sugar: in line with the national first-class standard.

[0066] Red Bean Granules:

[0067] 1. The particles are fresh and full

[0068] 2. The particle size is 2-8mm

[0069] The preparation method of the modulation milk of the present invention comprises the following steps:

[0070] 1) Take the material according to the following raw material formula (based on 1 ton):

[0071] a. Modified red bean milk:

[0072] 900.0 kg of milk, 60.0 kg of white sugar, 0.8 kg of glyceryl monostearate,

[0073] 0.3 kg of gelatin, 0.2 kg of carrageenan, 1.5 kg of microcrystalline cellulose,

[0074] 0.1 kg of gum arabic, 0.2 kg of pectin, 37 kg of red bean gum,

[0075] Red bean flavor 0.7 kg, milk flavor 0.3 kg.

[0076] b. Part of red bean jelly (calculated by mass percentage):

[0077] Sodium alginate...

Embodiment 2

[0089] Example 2 Modified milk with pineapple velvet

[0090] Milk: protein ≥ 2.95%, fat ≥ 3.0%, non-fat milk solids ≥ 8.5%

[0091] White granulated sugar: in line with the national first-class standard.

[0092] Pineapple velvet: solid content ≥ 60.0%;

[0093] 1. Fresh velvet;

[0094] 2. The length of pineapple fiber is 2-10mm, and the width is 0.2-1mm

[0095] The preparation method of the modulation milk of the present invention comprises the following steps:

[0096] 1) Take the material according to the following raw material formula (based on 1 ton):

[0097] a. Pineapple velvet milk:

[0098] Milk 880.0 kg, white sugar 63.0 kg, glyceryl monostearate 1.1 kg, diacetyl tartaric acid monoglyceride 0.3 kg, guar gum 0.3 kg, carrageenan 0.2 kg, gelatin 0.3 kg, xanthan gum 0.23 kg, pineapple velvet 23.0 kg, 17 kg of edible colloidal fiber, 0.8 kg of pineapple essence;

[0099] b. Edible colloidal fiber part (calculated by mass percentage):

[0100] Pectin 0.5%, white s...

Embodiment 3

[0112] Embodiment 3 Strawberry Colloidal Milk Beverage

[0113] Raw material standard:

[0114] Milk: protein ≥ 2.95%, fat ≥ 3.0%, non-fat milk solids ≥ 8.5%

[0115] White granulated sugar: in line with the national first-class standard.

[0116] Strawberry jam: solid content ≥ 45.0%;

[0117] making process:

[0118] 1) Take the material according to the following raw material formula (based on 1 ton):

[0119] a. Strawberry colloidal milk drink

[0120] 400.0 kg of milk, 20.0 kg of white sugar, 0.15 kg of acesulfame potassium,

[0121] Carboxymethylcellulose sodium 3.6 kg, citric acid 2.4 kg, lactic acid 1.8 kg,

[0122] 50 kg of strawberry gelatin, 0.5 kg of strawberry essence,

[0123] b. Strawberry colloidal part (calculated by mass percentage):

[0124] Konjac gum 0.2%, gelatin 0.25%, strawberry jam 25% g, white sugar 10.0%,

[0125] Purified water 69.55%;

[0126] 2) Ingredients 1: Put an appropriate amount of water into the sugar pot 1 to fully dissolve the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com