Mesoporous carbon supported Pt nano catalyst and preparation method thereof

A nano-catalyst, mesoporous carbon technology, applied in the field of materials, can solve the problem of small Pt nanoparticles, and achieve the effects of inhibiting agglomeration, good resistance to CO poisoning, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

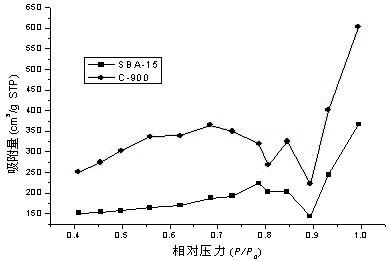

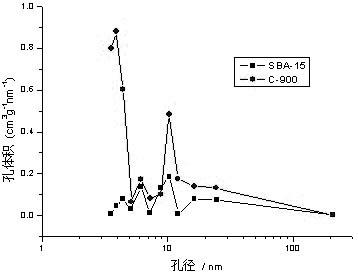

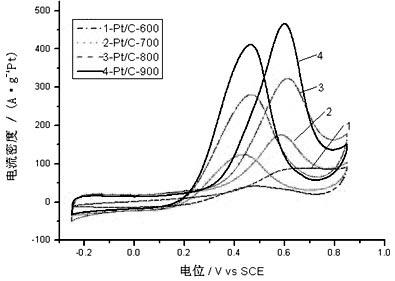

[0047] 1g SBA-15, 1.25g sucrose, 0.14g sulfuric acid, 5g water, strong ultrasonic for 20min, first bake at 100°C for 6h, then at 160°C for 6h. Grind the dark brown substance obtained, then add 0.8g sucrose, 0.09g sulfuric acid and 5g water in the same proportion, repeat baking at 100°C and 160°C for 6h, and grind again, then put it in the quartz tube In the furnace, the temperature was controlled at 600°C, 700°C, 800°C, and 900°C for 6 hours under a nitrogen atmosphere. Finally, infiltrate 30 mL of 10% hydrofluoric acid (HF) for 24 hours, suction filter, dry, grind and sieve with 200 meshes to obtain the corresponding media at temperatures of 600°C, 700°C, 800°C, and 900°C. Pore carbon is C-600, C-700, C-800, C-900;

[0048] Dissolve 30.0mg of mesoporous carbon corresponding to the above-mentioned different temperatures in 20mL of aqueous solution, raise the temperature to 40°C, stir magnetically (stirring rate 500 r / min), form a carbon slurry after 30min, and slowly add 7....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com