Method for manufacturing compound blade of agricultural harvester

A composite blade and manufacturing method technology, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of low service life, low hardness, low wear resistance, and affecting work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

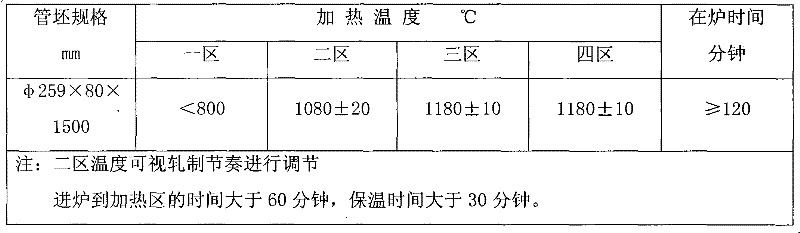

[0020] Production of 16MnV / 9Cr18MoV / 16MnV three-layer composite metal blades, the thickness of the outer, middle and inner layers are 38mm, 15mm, 35mm respectively, the diameter of the tube blank is 269.9mm, the length is 1605mm, the liquidus line of 16MnV is 1510 ℃, the liquidus of 9Cr18MoV The line is 1440°C.

[0021] 1. The material is selected according to the performance requirements of the finished product. The inner and outer base materials are selected from low-alloy high-strength structural steel 16MnV, and the middle layer is selected from high-hardness martensitic stainless steel 9Cr18MoV.

[0022] 2. Scrap steel can be used as the main raw material, smelted by electric arc furnace (intermediate frequency furnace) and refined by VOD furnace. The gas content and inclusion content are controlled during the steelmaking process; composition adjustment, slag removal and degassing treatment should be carried out after smelting. Refer to Table 1 for the smelting compositio...

Embodiment 2

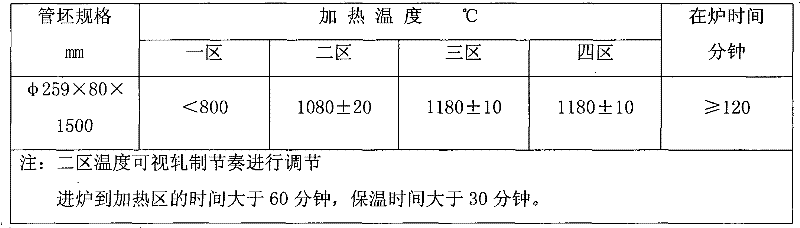

[0037] The production of 27SiMn / 9Cr18MoV / 27SiMn three-layer metal composite blades, the thickness of the outer, middle and inner layers are 38mm, 15mm, 35mm respectively, the diameter of the tube blank is 319.3mm, the length is 1655mm, the liquidus line of 27SiMn is 1497 ℃, 9Cr18MoV The liquidus is 1440°C.

[0038] 1. The material is selected according to the performance requirements of the finished product. The base material of the inner and outer layers is selected from high-strength steel 27SiMn, and the working layer of the middle layer is selected from high-hardness martensitic stainless steel 9Cr18MoV.

[0039] 2. Scrap steel is used as the main raw material, which is smelted by electric arc furnace (intermediate frequency furnace) and refined by VOD furnace. The gas content and inclusion content are controlled during the steelmaking process; composition adjustment, slag removal and degassing treatment should be carried out after smelting. Refer to Table 3 for the smelti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com