Propping agent particles and preparation method thereof

A technology of proppant and particles, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., and can solve the problems of poor fracture-making conductivity, affecting fracture-making ability, affecting fracture conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

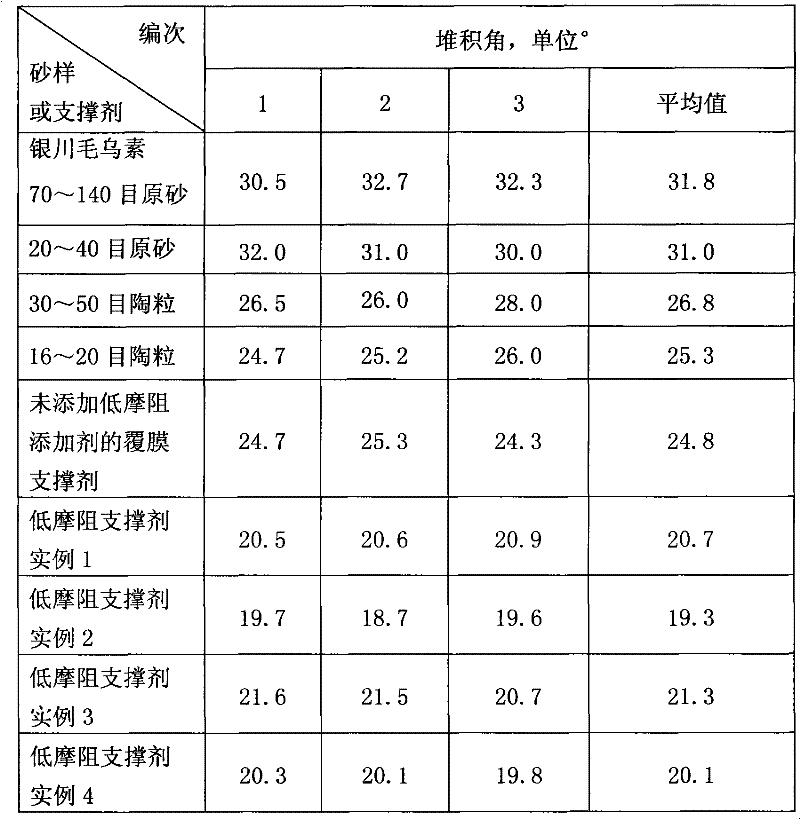

Examples

Embodiment 1

[0037] Heat 5% by mass of furan resin to its melting point, add 1% by mass of calcium fluoride to the molten furan resin, and stir evenly; add 0.1 to the 20 / 40 mesh quartz sand with 92% by mass % Silane coupling agent KH550, stir evenly; heat the quartz sand treated with silane coupling agent to 300℃, add the treated furan resin during heating and stir evenly; add 1% curing agent benzenesulfonate after cooling Acid chloride; adding 0.9% lubricant polyethylene wax and stirring uniformly; cooling the above mixture, crushing and sieving to obtain phenolic resin coated sand proppant, that is, low friction proppant.

Embodiment 2

[0039] Heat 30% by mass phenolic resin to its melting point, add 8% by mass calcium fluoride to the molten phenolic resin, and stir evenly; add 0.1 to 60% by mass 20 / 40 mesh quartz sand % Silane coupling agent KH550, stir evenly; heat the quartz sand treated with silane coupling agent to 100°C, add the treated phenolic resin during the heating process and stir evenly; add 1% curing agent imidazole after cooling; Adding 0.9% of lubricant polyethylene wax and mixing uniformly; cooling the above mixture, crushing and sieving to obtain phenolic resin coated sand proppant, that is, low friction proppant.

Embodiment 3

[0041] Heat 3% polystyrene to its melting point temperature, add 5% total mass percentage of polytetrafluoroethylene to the molten polystyrene, and stir evenly; for 20 / 40 mesh, 95% mass percentage of quartz Add 0.4% silane coupling agent KH550 to the sand and stir evenly; heat the quartz sand treated with the silane coupling agent to 400°C, add the treated polystyrene during the heating process and stir evenly; add 1% after cooling down The solidifying agent hexamethylenetetramine; adding 0.5% lubricant stearic acid amide and stirring uniformly; cooling the above mixture, crushing, and sieving to obtain polystyrene coated sand proppant, that is, low friction proppant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com