Method for recovering scandium and titanium in titanium white wastewater

A technology of titanium dioxide waste water and recovery method, which is applied in the direction of improving process efficiency, can solve the problems of neglecting the recovery of titanium element and not taking it into consideration, and achieves the effects of environmental protection technology, improved yield and reduced scandium cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

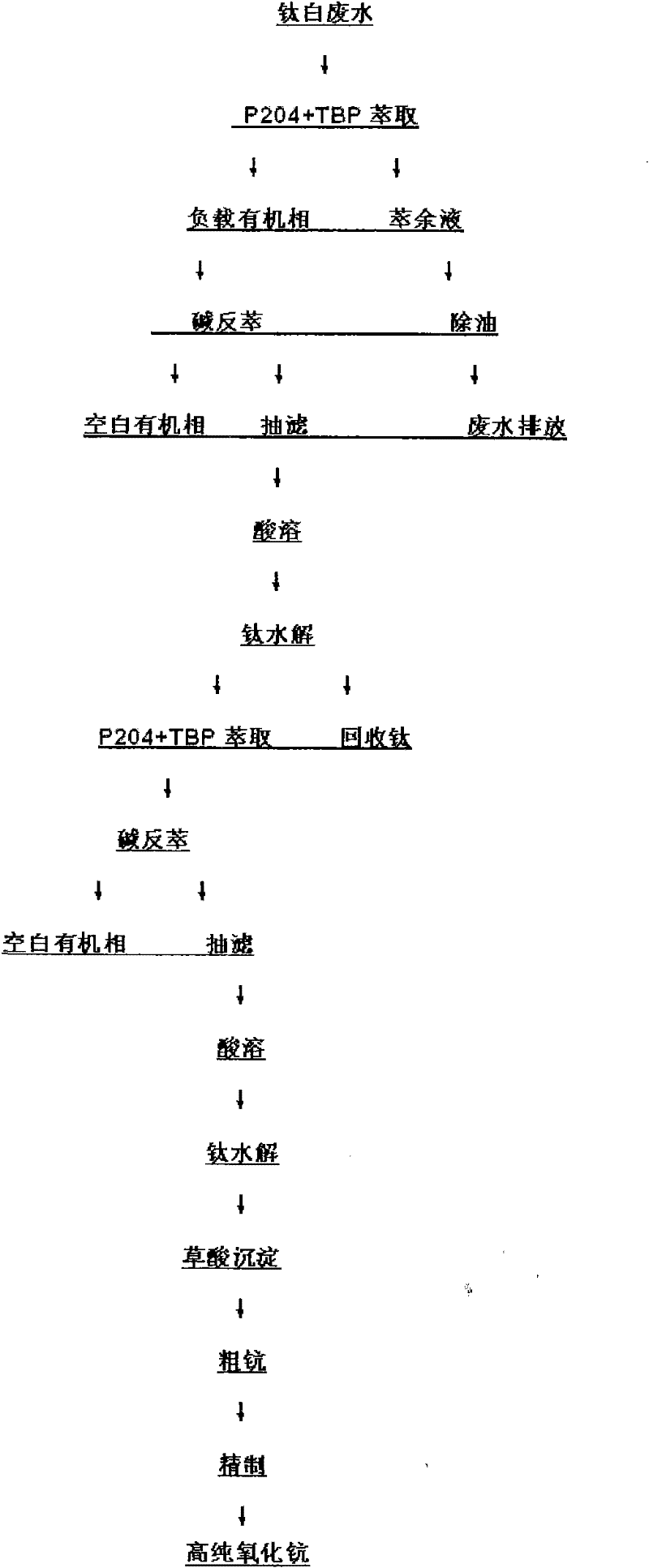

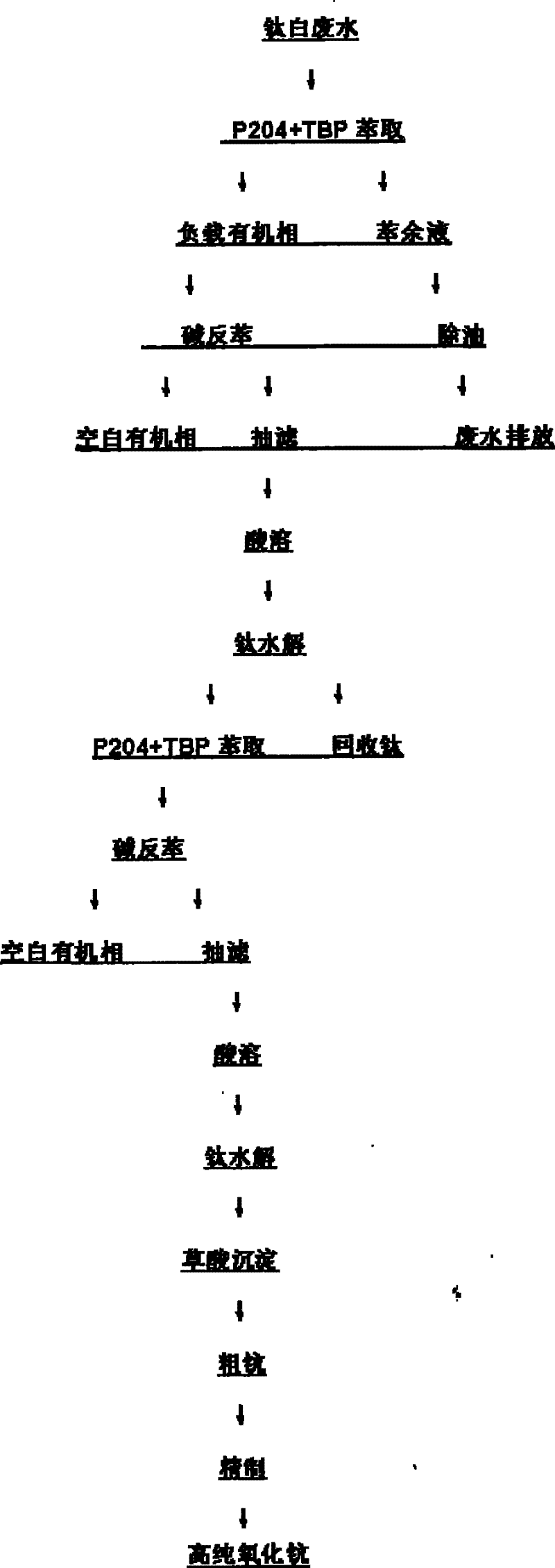

Method used

Image

Examples

Embodiment 1

[0019] 1000 liters of titanium dioxide wastewater in the 2M3 reactor, (acidity 5Mol H 2 SO 4 , containing scandium 16mg / liter, titanium 6g / liter, iron 30g / liter), add 50 liters of P2O4 and 4% TBP and the kerosene of remaining volume by volume fraction, carry out single-stage extraction, stir 20 minutes, stir The speed is 100 rpm, and the equilibrium time is 15 minutes; static stratification, the extraction rate of scandium is 90%, and the extraction rate of titanium is 40%. After linoleum treatment, the organic phase content in the water phase is 50mg / L, and it is discharged.

Embodiment 2

[0021] 500 liters of the organic phase after extraction in Example 1 was put into a 1.5M3 reaction kettle, and 500 liters of single-stage back-extraction with 1molNaOH and 0.7molNaCl lye were used, at a temperature of 70°C, stirred for 15 minutes, and the stirring speed was 120 rpm ;Static stratification, the stripping rate of scandium is 98%, and the stripping rate of titanium is 98%. Dissolve the stripped alkali cake with 9molH2SO4, adjust the pH to 0.5 with Na2CO3, heat to boiling for 10 minutes, hydrolyze titanium, and recover titanium by filtration; the hydrolysis rate of titanium is more than 90%, and the loss of scandium is 1%, Ti / Sc= 50:1.

Embodiment 3

[0023] 500 liters of mother liquor after hydrolysis in embodiment 2, put into 1.5M3 Reactor, first use H2SO4Adjust acidity 5mol and carry out second extraction and back extraction again, condition is the same as embodiment 1, embodiment 2. After the second hydrolysis, Ti / Sc=1:1, control pH=2, precipitate scandium with oxalic acid, and burn at 800C° for 1 hour to obtain 95% crude scandium oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com