Method for quickly carbonizing lignite at high temperature and equipment thereof

A high-temperature carbonization, high-temperature rapid technology, used in coke cooling, special forms of dry distillation, petroleum industry and other directions, can solve the problem of low utilization rate of lignite, and achieve the effect of strengthening the carbonization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

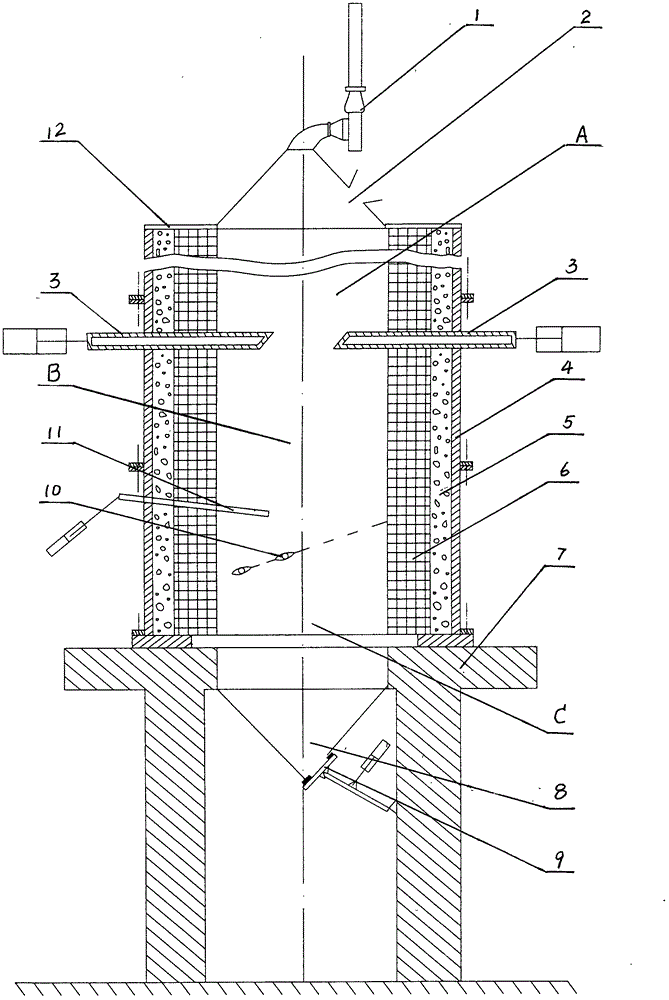

[0013] combine figure 1 , full-automatic lignite high-temperature carbonization vertical kiln, including 12 circular kiln bodies, the kiln height and diameter are determined according to the actual production volume, the general kiln height is 3-50 meters, the kiln body diameter is 1-10 meters, and it is designed to feed 25 tons at a time , the height of the kiln body used is 15 meters, the diameter of the kiln body is 2 meters, and the wall of the kiln body is composed of a refractory brick layer 6, an insulation layer 5 and a kiln body shell 4, which have the functions of heat preservation and preventing heat loss; the kiln body 12 is placed on the concrete base 7, there is a discharge space under the base 7, so as to facilitate the discharge and placement of the charging device; the upper part of the kiln body is the feed port 2 and the air induction port connected with the induced draft fan 1, and the lower part has a discharge port 8. The mouth 8 has an automatic control ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat | aaaaa | aaaaa |

| volatile matter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com