Double-power liquid stream battery electric pile structure and liquid stream battery containing electric pile

A liquid flow battery and electric stack technology, which is applied to fuel cell components, fuel cells, regenerative fuel cells, etc., can solve problems such as increasing electrolyte flow resistance, increasing battery polarization, and power scale constraints, achieving Effects of reducing polarization, reducing potential difference, and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

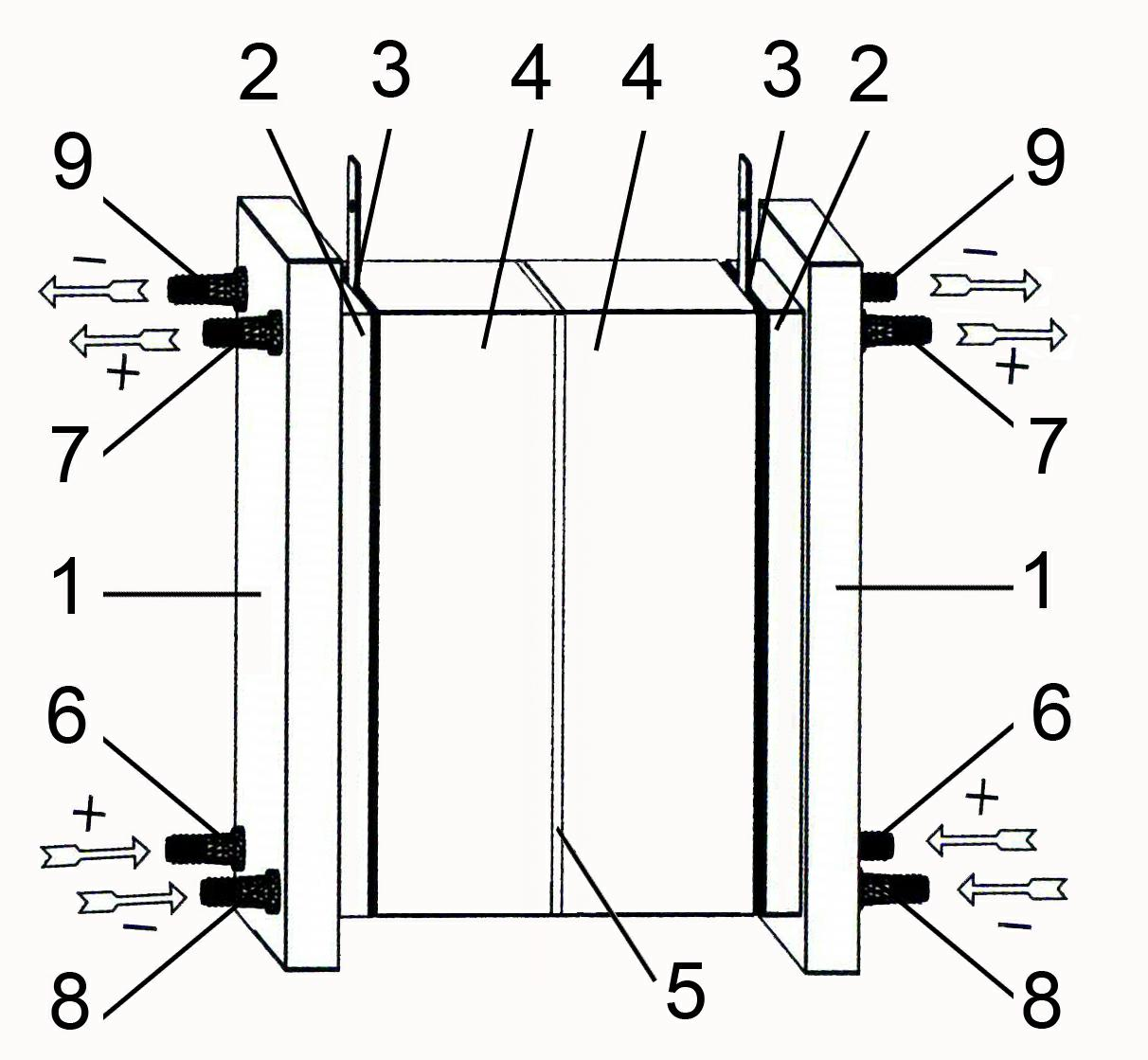

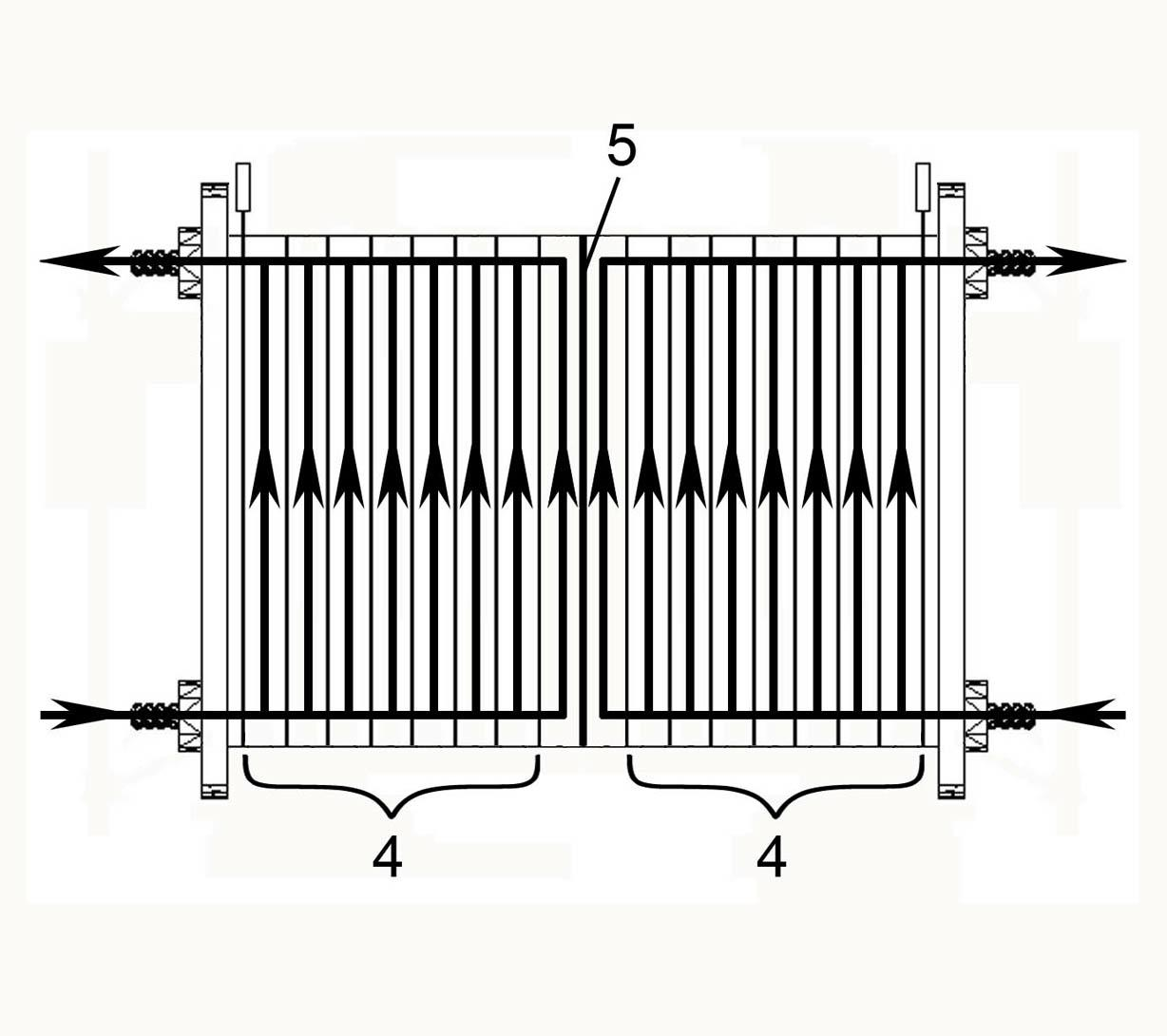

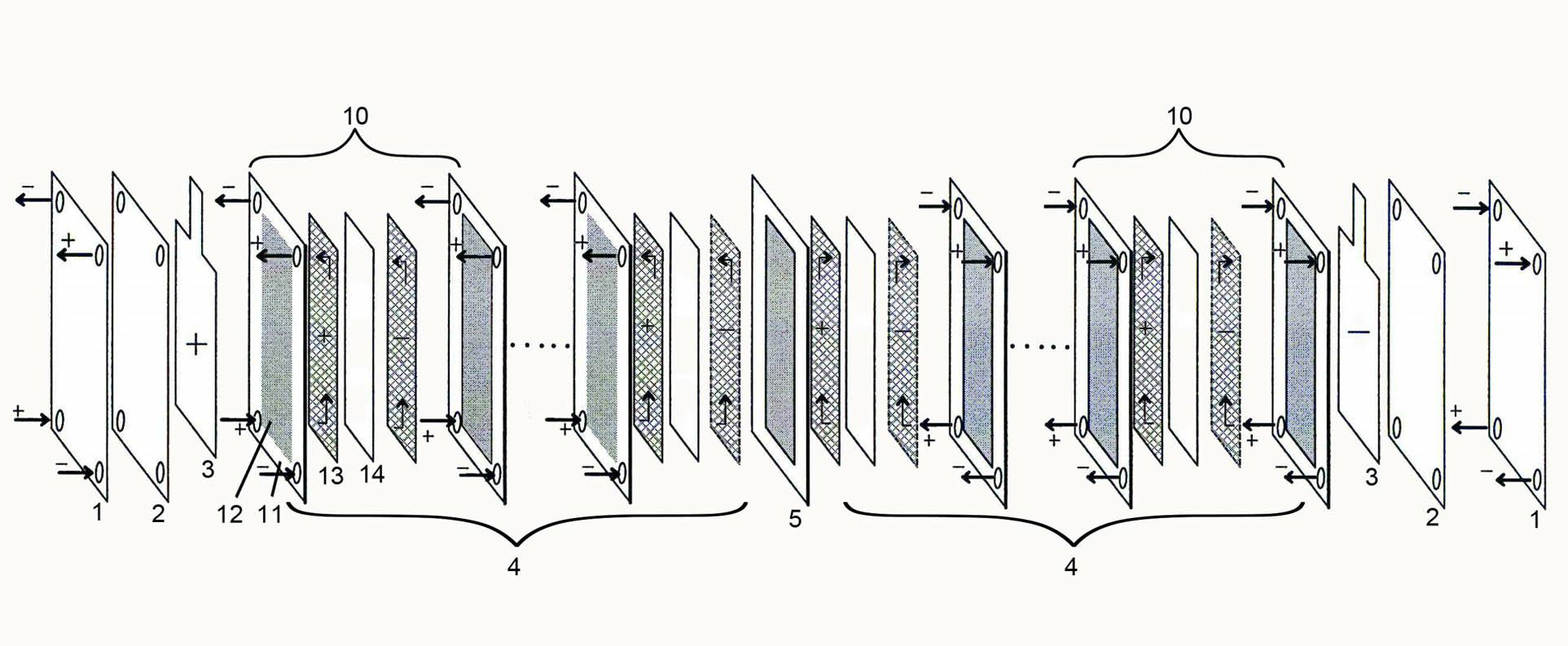

[0029] The multi-channel end plate is a steel plate with a thickness of 3cm, and the diameter of the electrolyte inlet and outlet is 2cm; the multi-channel insulating plate is a PE plate, and the diameter of the electrolyte channel hole is 2cm; The battery electrode area is the same; the number of single cells in the sub-stack is 10, the electrolyte guide frame is made of PE, the bipolar plate is a conductive plastic plate, and the electrolyte guide frame and the bipolar plate are laser welded. It is graphite felt with an area of 5000cm 2 , The diaphragm uses a cation exchange membrane, the thickness of the single cell is 1.5cm, and the power of the sub-stack is 5kW. The liquid flow separation frame is made of the same material as the electrolyte guide frame, and it is welded with the bipolar plate by laser. The capacity of the prepared all-vanadium ion redox flow battery is 20kWh. at 80mA / cm 2 Under the charging and discharging conditions of the battery, the voltage effi...

Embodiment 2

[0031] The multi-channel end plate is a steel plate with a thickness of 3cm, and the diameter of the electrolyte inlet and outlet is 2cm; the multi-channel insulating plate is a PE plate, and the diameter of the electrolyte channel hole is 2cm; The battery electrode area is the same; the number of single cells in the sub-stack is 20, the electrolyte guide frame is made of PE, the bipolar plate is a conductive plastic plate, the electrolyte guide frame and the bipolar plate are laser welded, and the electrodes It is graphite felt with an area of 8000cm 2 , The diaphragm is a cation exchange membrane, the thickness of the single cell is 1.5cm, and the power of the sub-stack is 10kW. The liquid flow separation frame is made of the same material as the electrolyte guide frame, and it is welded with the bipolar plate by laser. The capacity of the prepared all-vanadium ion redox flow battery is 40kWh. at 80mA / cm 2 Under the charging and discharging conditions of the battery, th...

Embodiment 3

[0033] The multi-channel end plate is a steel plate with a thickness of 3cm, and the diameter of the electrolyte inlet and outlet is 2cm; the multi-channel insulating plate is a PE plate, and the diameter of the electrolyte channel hole is 2cm; The battery electrode area is the same; the number of single cells in the sub-stack is 30, the electrolyte guide frame is made of PE, the bipolar plate is a conductive plastic plate, and the electrolyte guide frame and the bipolar plate are laser welded. It is graphite felt with an area of 4000cm 2 , The diaphragm is a cation exchange membrane, the thickness of the single cell is 1.5cm, and the power of the sub-stack is 10kW. The liquid flow separation frame is made of the same material as the electrolyte guide frame, and it is welded with the bipolar plate by laser. The capacity of the prepared all-vanadium ion redox flow battery is 40kWh. at 80mA / cm 2 Under the charging and discharging conditions of the battery, the voltage effic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com