Preparation method of asterias amurensis polysaccharide extract and medical applications thereof

A technology for extracting polysaccharides from the spiny sea of thorns is applied in the research and development field of pharmaceutical products, and can solve the problems of less research on polysaccharides.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

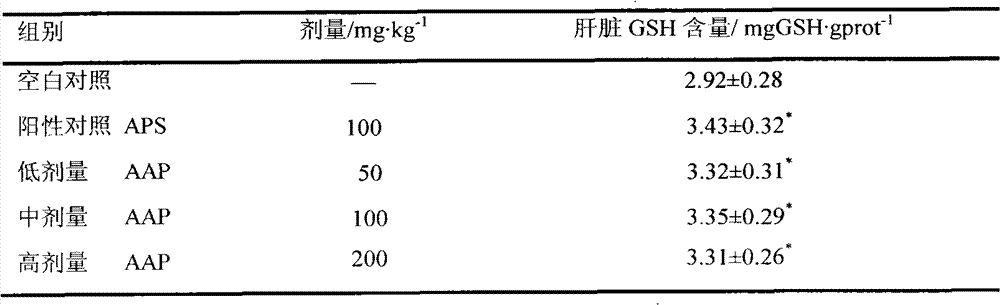

Image

Examples

Embodiment 1

[0014] Step (1): get rid of the internal organs of the spiny sea, the body wall is dried, pulverized and passed through a 60-mesh sieve, and 1000g of powder is percolated with 4000mL of ethanol in a percolation device to obtain a filter residue;

[0015] Step (2): add the filter residue in step (1) into 5000mL 0.1mol / L NaOH solution, stir at room temperature overnight, and centrifuge to obtain a supernatant;

[0016] Step (3): adjust the pH of the supernatant in step (2) to 7.0, add 1% Bacillus subtilis neutral protease for enzymatic hydrolysis overnight, and centrifuge to obtain the supernatant;

[0017] Step (4): adjust the pH of the supernatant in step (3) to 8.0, add 5% hydrogen peroxide, decolorize to light yellow at 50 ° C, and concentrate under reduced pressure to obtain a concentrated solution;

[0018] Step (5): deproteinize the concentrated solution in step (4) with Sevage reagent twice, then add 5 times the amount of absolute ethanol, and centrifuge to obtain precip...

Embodiment 2

[0022] Step (1): get rid of the internal organs of the spiny sea, the body wall is dried, pulverized and passed through a 60-mesh sieve, and 800g of powder is percolated with 3200mL of ethanol in a percolation device to obtain a filter residue;

[0023] Step (2): add the filter residue in step (1) into 4000mL 0.1mol / L NaOH solution, stir at room temperature overnight, and centrifuge to obtain a supernatant;

[0024] Step (3): adjust the pH of the supernatant in step (2) to 7.0, add 1% Bacillus subtilis neutral protease for enzymatic hydrolysis overnight, and centrifuge to obtain the supernatant;

[0025] Step (4): adjust the pH of the supernatant in step (3) to 8.0, add 5% hydrogen peroxide, decolorize to light yellow at 50 ° C, and concentrate under reduced pressure to obtain a concentrated solution;

[0026] Step (5): deproteinize the concentrated solution in step (4) with Sevage reagent twice, then add 4 times the amount of absolute ethanol, centrifuge to obtain precipitati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com