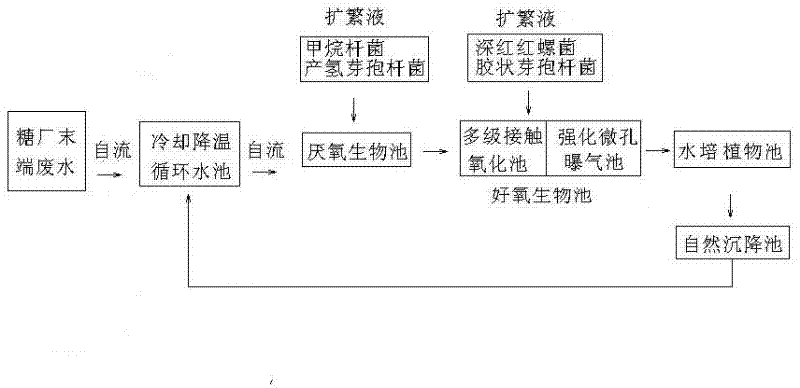

Three-level biological purification process for disposing terminal waste water from sugar refinery

A biological purification and wastewater technology, applied in biological water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of substandard drainage COD, long cultivation or restoration period, and high equipment investment problems, to achieve the effect of fast film hanging, short construction period and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

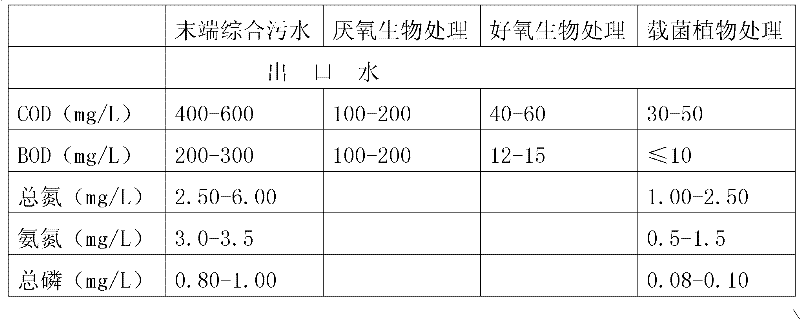

[0017] Daily sewage 1500~2000m 3 Sugar factory, according to 600 ~ 800m 3 / h treatment capacity, then add the anaerobic heterotrophic bacteria and Methanobacteria mixed propagation solution 0.6 in the anaerobic biological treatment tank 3 , add 0.8m in the aerobic biological treatment pool 3 Rhodospirillum and colloidal bacillus are mixed to expand the propagation liquid, and 70% of the floating plate plants with the compound bacterial liquid are loaded in the plant hydroponic tank to occupy the water surface. The purified water COD<40mg / L and BOD<10mg / L after this three-stage biological treatment, all the purified water is recycled and reused.

[0018] Table 1: Results of three-stage biological purification treatment of sugar factory wastewater

[0019]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com