Biomacromolecule skin care product with flexible nanoliposome as carrier and preparation method of biomacromolecule skin care product

A technology of nano-liposomes and biomacromolecules, applied in cosmetic preparations, skin care preparations, medical preparations containing active ingredients, etc., can solve the problem of liposome vesicles entering deep skin cells and low encapsulation efficiency and other problems, to achieve the effect of good coating, stable shape of the finished product, and high encapsulation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

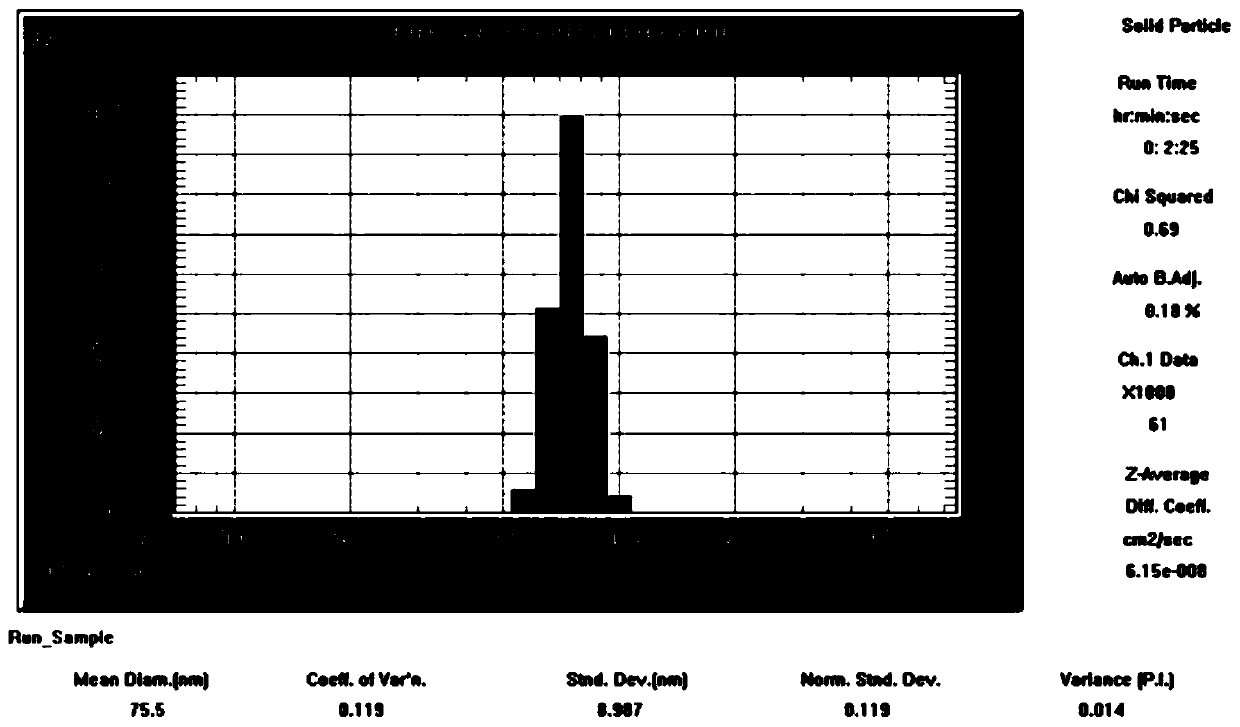

Method used

Image

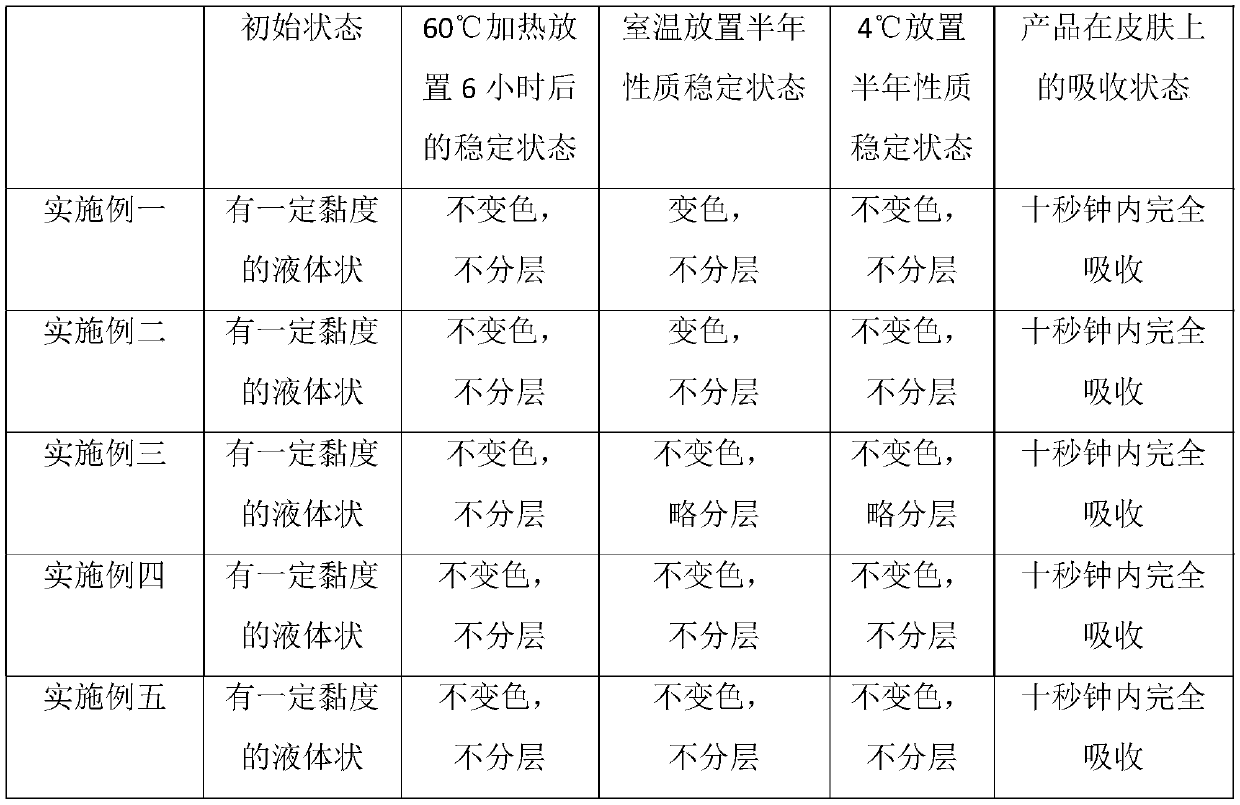

Examples

Embodiment 1

[0039] Weigh and mix 493g of deionized water, 20g of sodium cholate, 10g of Tween-60, 50g of ascorbic acid, 10g of hexapeptide, 2g of oligopeptide-1, 50g of allantoin, 10g of sodium hyaluronate, and 50g of licorice extract, Heat to 60°C and stir with 200r / min magnetic force until all components are completely dissolved. Continue to insulate and stir for 30 minutes to become the water phase.

[0040] Mix 50g of hydrogenated soybean lecithin, 20g of octadecylamine, 100g of ethanol, 10g of Span-60, 50g of tocopherol, and 50g of green tea extract, heat to 60°C, and stir with 100r / min magnetic force to dissolve completely. Continue to insulate and stir for 30 minutes to become the organic phase. Slowly inject the mixed organic phase into the water phase, while maintaining temperature control at 60°C, and quickly mix the two phases with 500r / min magnetic stirring to form a liposome system. Stir continuously at temperature control for 5 minutes to ensure the uniformity and stability...

Embodiment 2

[0042] Weigh and mix 643g of deionized water, 16g of sodium cholate, 3g of ajirelin, 28g of Tween-80, 10g of ascorbic acid, 10g of carnosine, 10g of allantoin, and 20g of ectoine, and heat to 55°C, 600r / min Stir with a stirring paddle until the ingredients are completely dissolved. Continue to insulate and stir for 30 minutes to become the water phase. Weigh 50g of egg yolk lecithin, 100g of ethanol, 5g of stearylamine, 50g of chamomile extract, and 30g of green tea extract, and mix them, heat to 55°C, stir with 600r / min magnetic force to completely dissolve each component, and keep stirring for 10 minutes to become organic Mutually. Slowly inject the mixed organic phase into the water phase, while maintaining temperature control at 55°C, and quickly mix the two phases to form a liposome system with a high-speed shear of 7000r / min. After the organic phase is completely injected, continue to shear for 2 minutes to ensure uniformity of the system. Stable and become emulsified...

Embodiment 3

[0044] Mix 435g of deionized water, 11g of sodium cholate, 100g of yeast fermentation filtrate (containing about 10g of biological macromolecules, and the rest is water), 5g of glutathione, 50g of glycerin, 2g of phloretin, 10g of dipotassium glycyrrhizinate, rose 10g of eggplant extract was weighed and mixed, heated to 40°C, stirred magnetically at 500r / min until each component was completely dissolved, and kept stirring for 10 minutes to form a water phase. Mix 100g of hydrogenated soybean lecithin, 30g of octadecylamine, 200g of ethanol, 5g of retinyl propionate, and 20g of hydrogenated castor oil polyoxyethylene-40, heat to 40°C, and stir magnetically at 100r / min until all ingredients are completely dissolved Continue to insulate and stir for 10 minutes to become an organic phase. Slowly inject the mixed organic phase into the water phase, while maintaining temperature control at 50°C, and quickly mix the two phases at a high speed of 12000r / min to form a liposome system. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com