Preparation method and application of cracking catalyst for biomass gasification tar

A tar cracking and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxides/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of catalyst tar cracking ability decline and increase gasification gas ash content , low mechanical strength of dolomite, etc., to achieve the effect of improving the ability to resist H2S poisoning, improve the degree of dispersion, and improve the ability to resist carbon deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

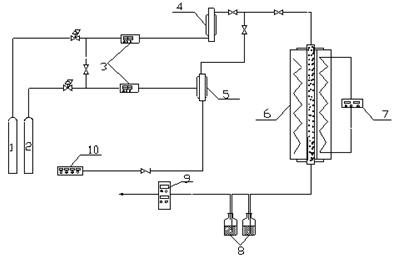

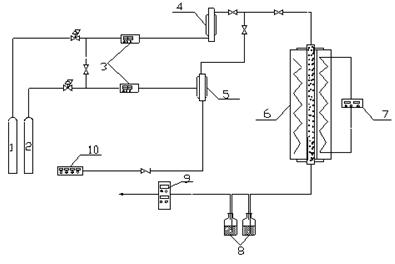

Image

Examples

Embodiment 1

[0031] A kind of preparation method of biomass gasification tar cracking catalyst is as follows:

[0032] ① Carrier pretreatment: Put 20 g olivine into a crucible, then place it in a muffle furnace, and calcinate it at 900°C for 8 hours, then sieve the calcined olivine to prepare 30-mesh olivine carrier particles .

[0033] ②Introduction of the main active component: mix 10 g of 30 mesh olivine carrier particles with 100 mL of 0.1 g / mL Ni(NO 3 ) 2 ·6H 2 O aqueous solution was mixed, stirred at 50°C for 6 hours, after impregnation, dried at 110°C for 12 hours, the obtained sample was placed in a muffle furnace, calcined at 800°C for 12 hours, and the calcined catalyst was placed in Cool to room temperature in a desiccator, then grind.

[0034] ③Introduction of functional co-active components: Mix 10 g of ground loaded olivine particles with 100 mL of 0.08 g / mL Ce(NO 3 ) 3 ·6H 2 O aqueous solution was mixed, stirred at 60°C for 10 hours, after impregnation, dried at 110°C...

Embodiment 2

[0041] A preparation method of a biomass gasification tar cracking catalyst is the same as Example 1. The difference is that the concentration of active components is different, and the prepared biomass gasification tar cracking catalyst consists of NiO (2%) , MgO (15%), CeO 2 (7%), WO 3 (10%), peridot (66%).

[0042] The catalyst was evaluated under the same conditions as in Example 1, and it was found that the conversion rate of tar was only 72%, and the carbon formation on the surface of the catalyst was not obvious.

Embodiment 3

[0044] A preparation method of a biomass gasification tar cracking catalyst is the same as Example 1. The difference is that the concentration of the active component is different, and the prepared biomass gasification tar cracking catalyst is composed of NiO (9%) , MgO (15%), CeO 2 (2%), WO 3 (10%), peridot (64%).

[0045] The catalyst was evaluated under the same conditions as in Example 1, and it was found that the tar conversion rate was 94% after continuous operation for 8 hours, the surface of the catalyst was seriously carbonized, and the catalyst bed was blocked.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com