Jointed toothed V belt

A technology of tooth type and combination, applied in the direction of V-belt, belt/chain/gear, mechanical equipment, etc., can solve the problems of poor processability, poor dynamic fatigue resistance, poor tear resistance, etc., to achieve improved physical properties, cold resistance, etc. The effect of improved performance, reliable and stable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

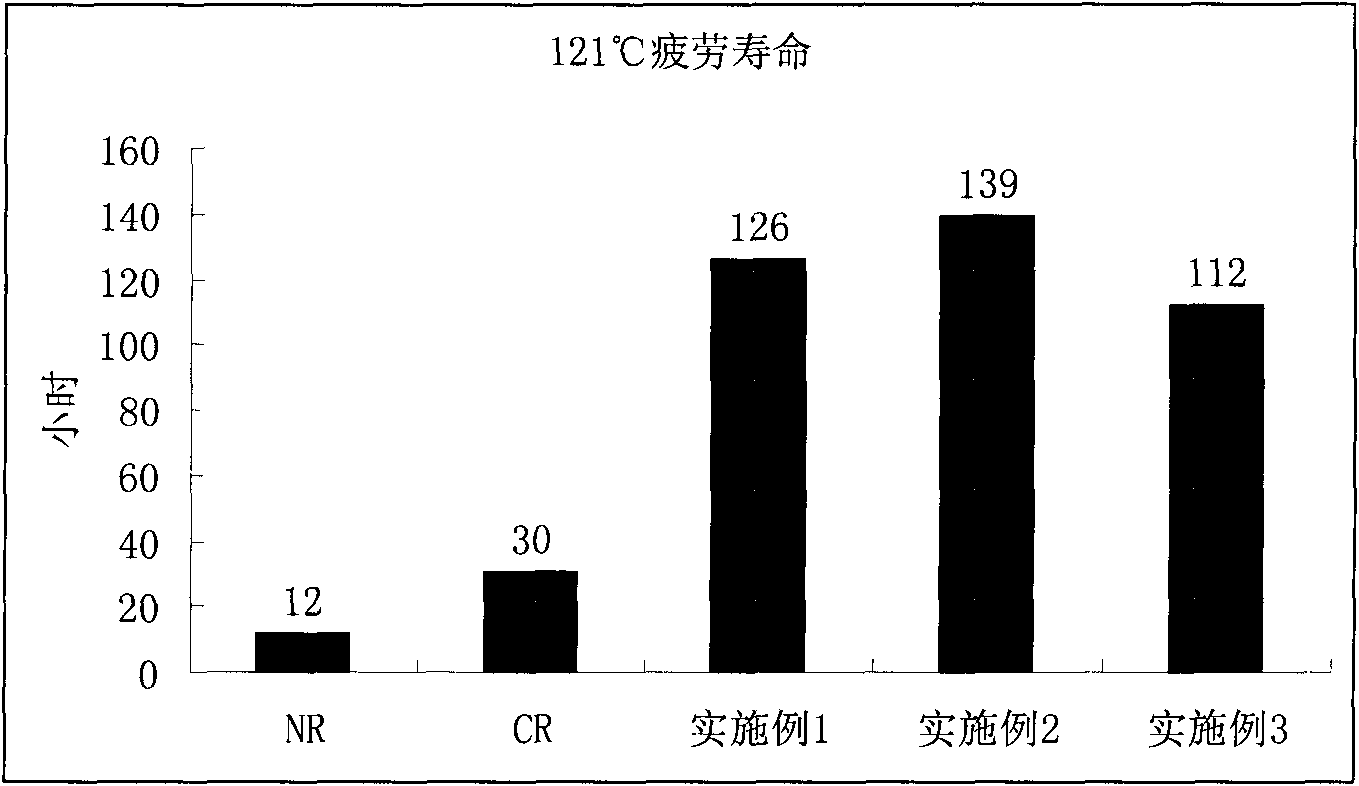

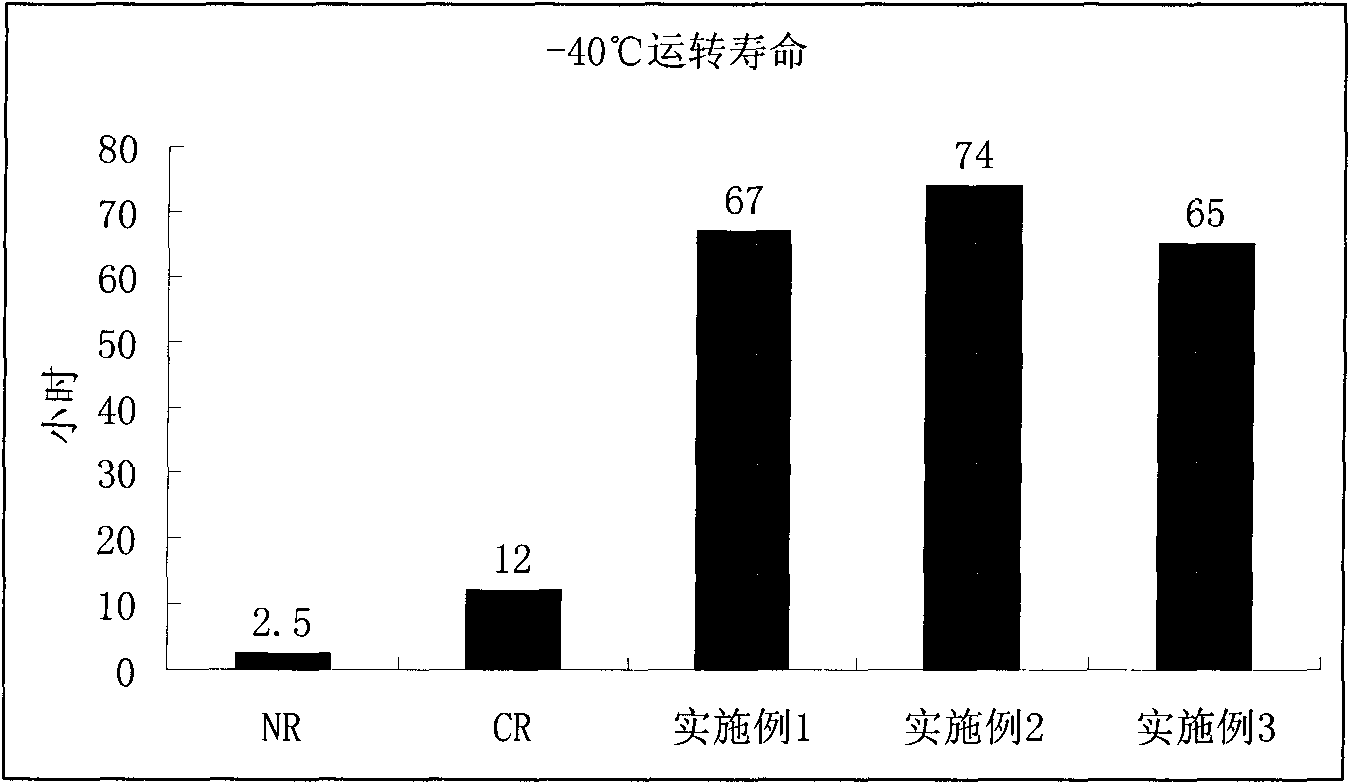

Embodiment 1

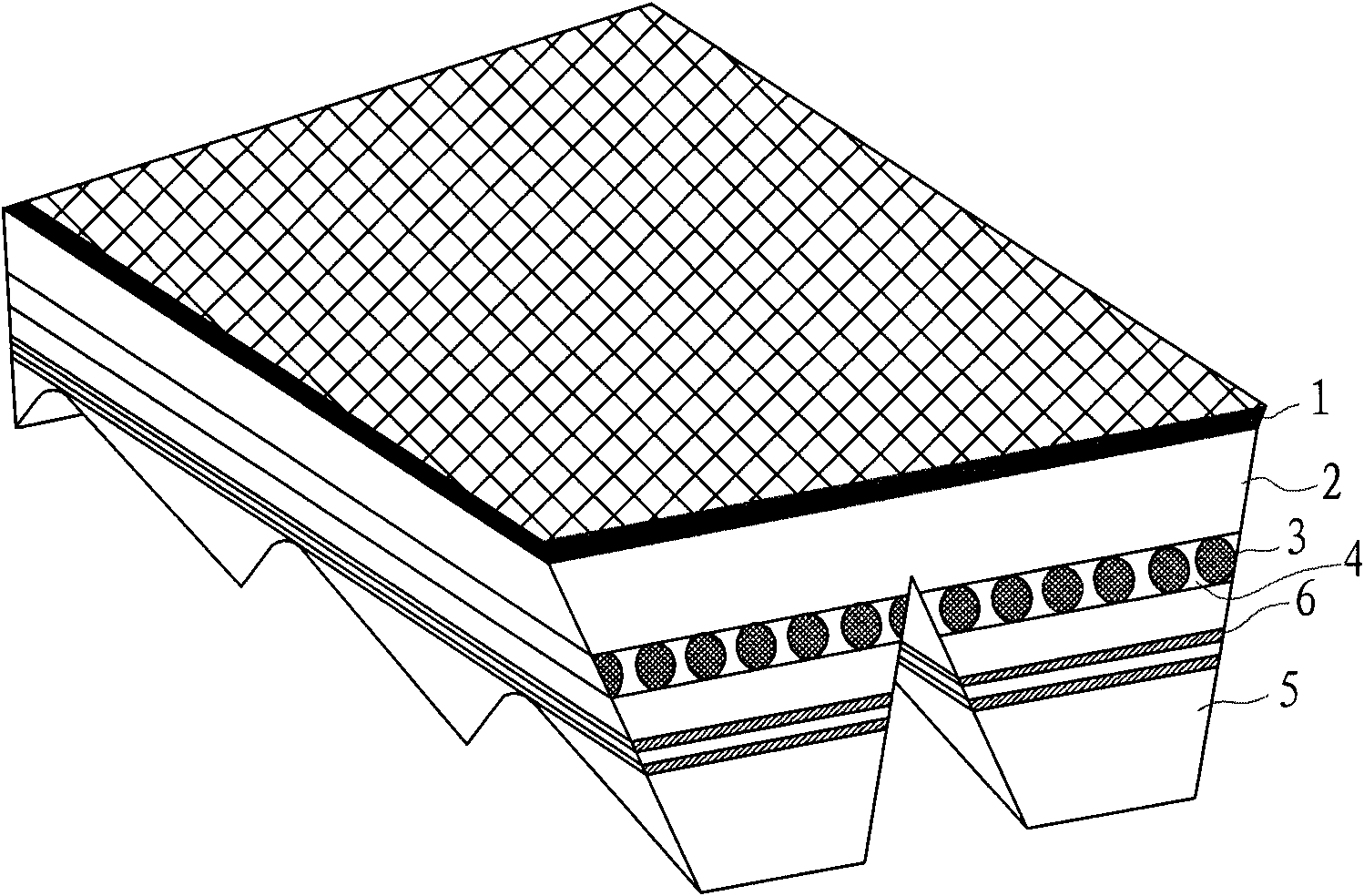

[0022] Embodiment 1: as figure 1 As shown, the combined toothed V-belt in this embodiment includes a top fabric layer 1, a stretch layer 2, an adhesive layer 4 and a compression layer 5 from the outside to the inside. The adhesive layer 4 has a strength layer and a compression layer 5 respectively. A pressure-resistant layer 6 is distributed in it. Among them, the main rubber of the stretching layer, adhesive layer and compression layer is EPDM; °Warp and weft woven canvas; the strength layer is polyester cord treated with EPDM latex; the compression layer is polyester cord treated with EPDM latex. The top fabric layer is used to protect the belt surface and improve the wear resistance and scratch resistance of the belt surface; the strength layer is used to bear the longitudinal tension of the V-belt; the stretch layer is used to improve the transverse rigidity of the V-belt and ensure the stress position of the center of the strength layer ;The adhesive layer can enhance t...

Embodiment 2

[0031] The formula of the adhesive layer material is: EPDM: 55 kg; modified glue: 2.0 kg; zinc oxide: 2.7 kg; stearic acid: 0.5 kg; anti-aging agent RD (2,2,4-trimethyl-1,2 -dihydroquinoline polymer): 1.1 kg; antiaging agent BLE-W: 1.2 kg; adhesive: 5.6 kg; carbon black: 15 kg; paraffin oil: 3.0 kg; white carbon black: 12.5 kg; crosslinking agent DCP (Dicumyl Peroxide, dicumyl peroxide): 4.9 kg; co-crosslinking agent TAIC (Trially isocyanurate, triallyl isocyanurate): 0.3 kg.

[0032] The formulations for both the tensile and compressive layers are:

[0033] EPDM: 53 kg; modified rubber: 1.5 kg; zinc oxide: 2.5 kg; stearic acid: 0.4 kg; old agent RD: 1.0 kg; anti-aging agent BLE-W: 1.1 kg; adhesive: 4.6 kg; carbon black : 13 kg; paraffin oil: 2.6 kg; white carbon black: 10.0 kg; polyester staple fiber (after EPDM latex treatment, length 2-3mm): 13 kg; crosslinking agent DCP: 3.7 kg; co-crosslinking agent TAIC : 0.2 kg.

Embodiment 3

[0035] The formula of the adhesive layer material is: EPDM: 54 kg; modified glue: 1.5 kg; zinc oxide: 2.7 kg; stearic acid: 0.5 kg; anti-aging agent RD (2,2,4-trimethyl-1,2 -dihydroquinoline polymer): 1.1 kg; antiaging agent BLE-W: 1.2 kg; binder: 5.6 kg; carbon black: 15 kg; paraffin oil: 3.5 kg; white carbon black: 12.5 kg; crosslinking agent DCP (Dicumyl Peroxide, dicumyl peroxide): 4.8 kg; co-crosslinking agent TAIC (Trially isocyanurate, triallyl isocyanurate): 0.3 kg.

[0036] The formulations for both the tensile and compressive layers are:

[0037] EPDM: 51 kg; modified rubber: 0.7 kg; zinc oxide: 2.5 kg; stearic acid: 0.4 kg; old agent RD: 1.0 kg; anti-aging agent BLE-W: 1.1 kg; adhesive: 4.6 kg; : 13 kg; paraffin oil: 2.6 kg; white carbon black: 10.0 kg; polyester staple fiber (after EPDM latex treatment, length 2-3mm): 10 kg; crosslinking agent DCP: 3.7 kg; co-crosslinking agent TAIC : 0.2 kg.

[0038] In order to ensure that the length of the combined toothed V-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com