Air-conditioning system of closed artificial light plant factory

An air-conditioning system and artificial light technology, applied in air-conditioning systems, botany equipment and methods, heating and ventilation control systems, etc., can solve the problem of unbalanced air-conditioning running time, large capacity of air-conditioning systems, and large difference in cooling load between day and night, etc. problem, to achieve the effect of reducing installed capacity, low ambient temperature at night, and increasing cooling load at night

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

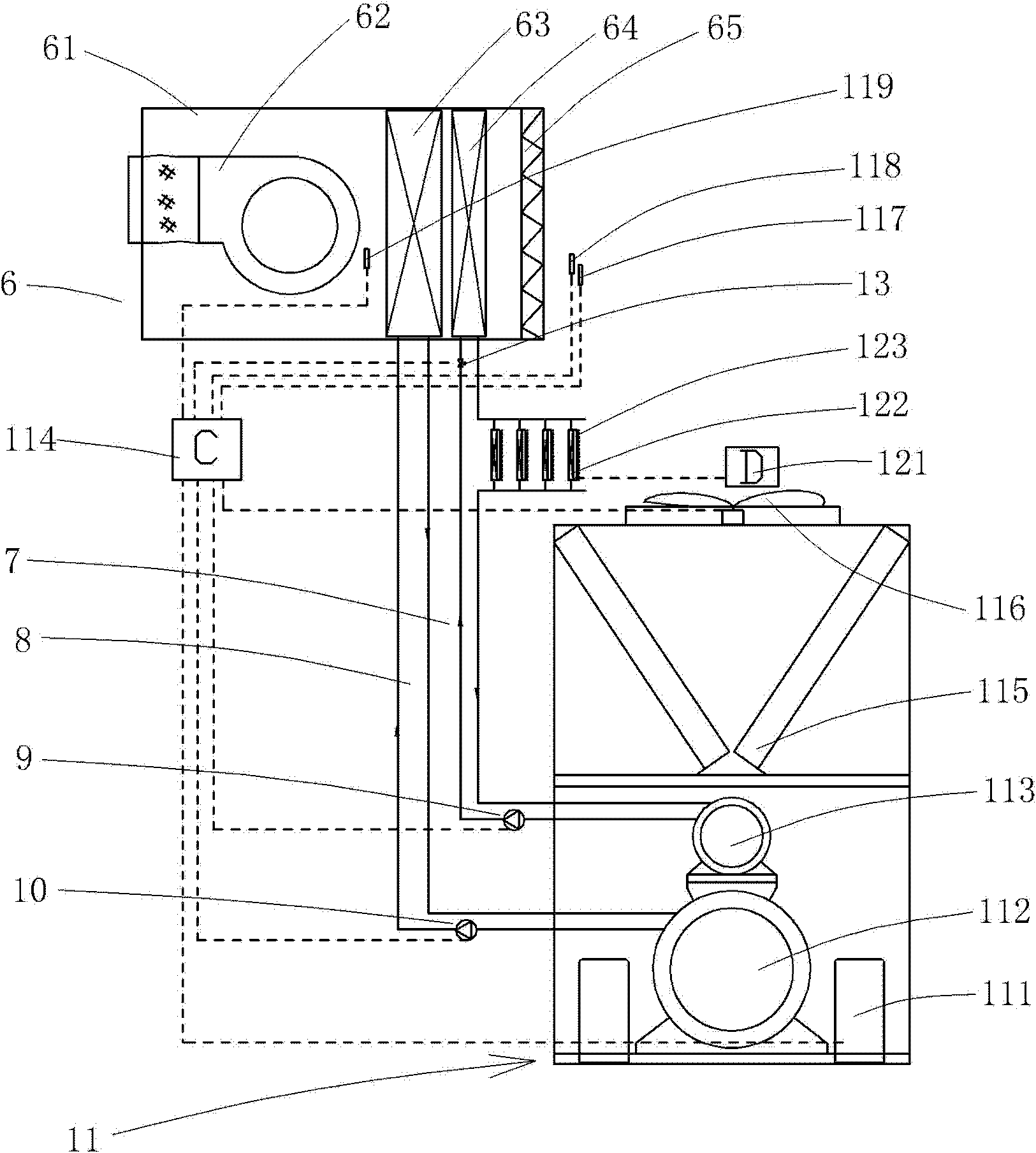

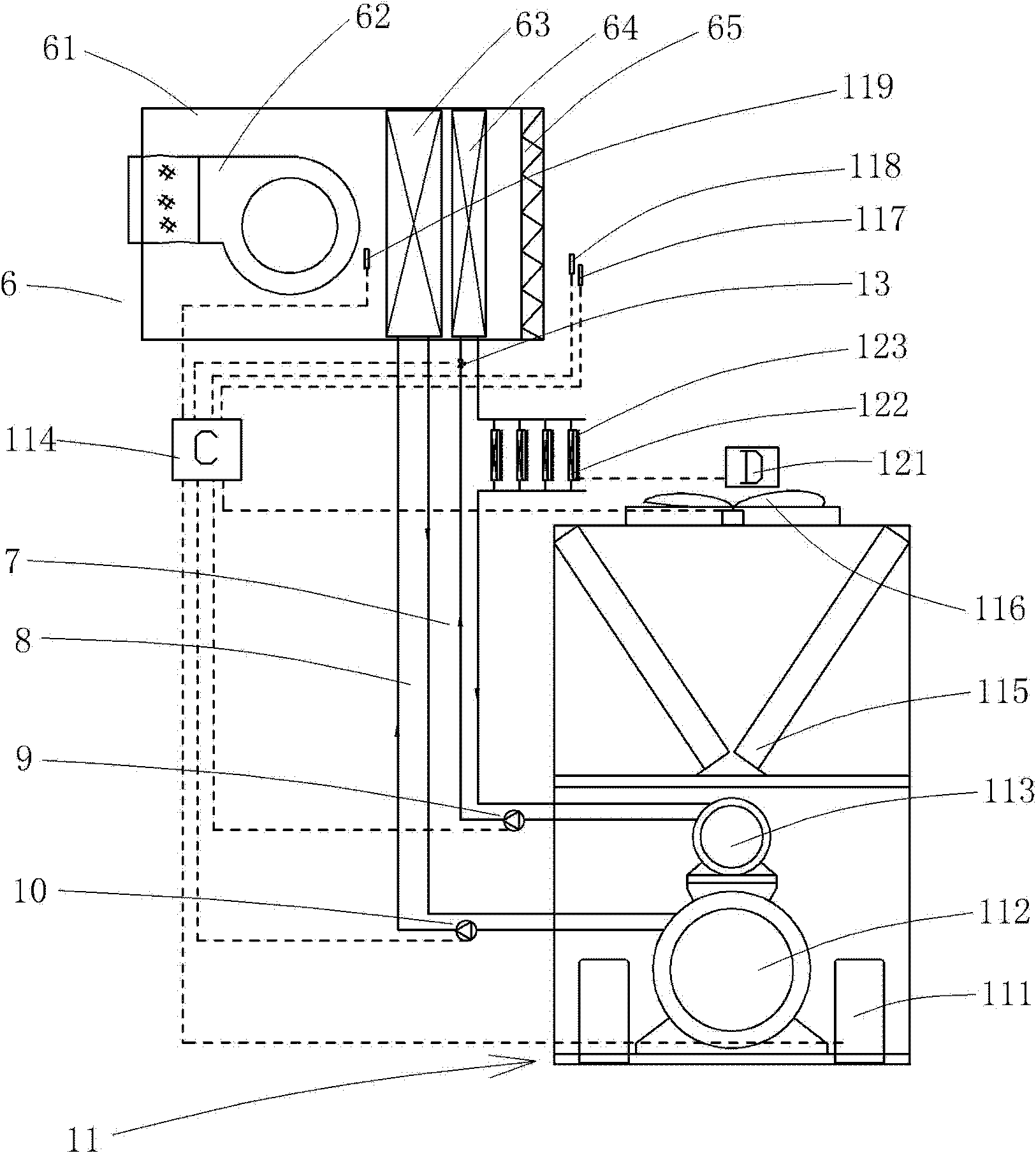

[0025] Example: see figure 1 , the air-conditioning system of the closed artificial light plant factory of the present embodiment,

[0026] Including air handling unit 6, artificial light source, 123 artificial light source heat recovery device 122, timing controller 121, heat recovery type air conditioning unit 11;

[0027] The air handling unit casing 61, fan 62 and air filter 65 form a public air duct. The surface cooler 63 and the heating coil 64 are connected in series in the common air duct, and the air flow first flows through the heating coil 64 and then flows through the surface cooler 63 . The heat recovery heat exchanger 113 utilizes the heat of condensation discharged from the compressor 111 during the cooling of the heat recovery type air-cooled heat pump chiller and hot water unit or the heat dissipation of the artificial light source heat dissipation recovery device 122 to produce hot water, and passes through the hot water circulation pump 9 and the hot water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com