Method for manufacturing metal shell power supply nameplate based on laser technology

A technology of metal casing and laser technology, applied in printing, anodizing, etc., can solve the problems of cost loss, prolonging the production cycle, easy to fall off, etc., and achieve the effect of reducing direct cost, reducing management cost and simplifying the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

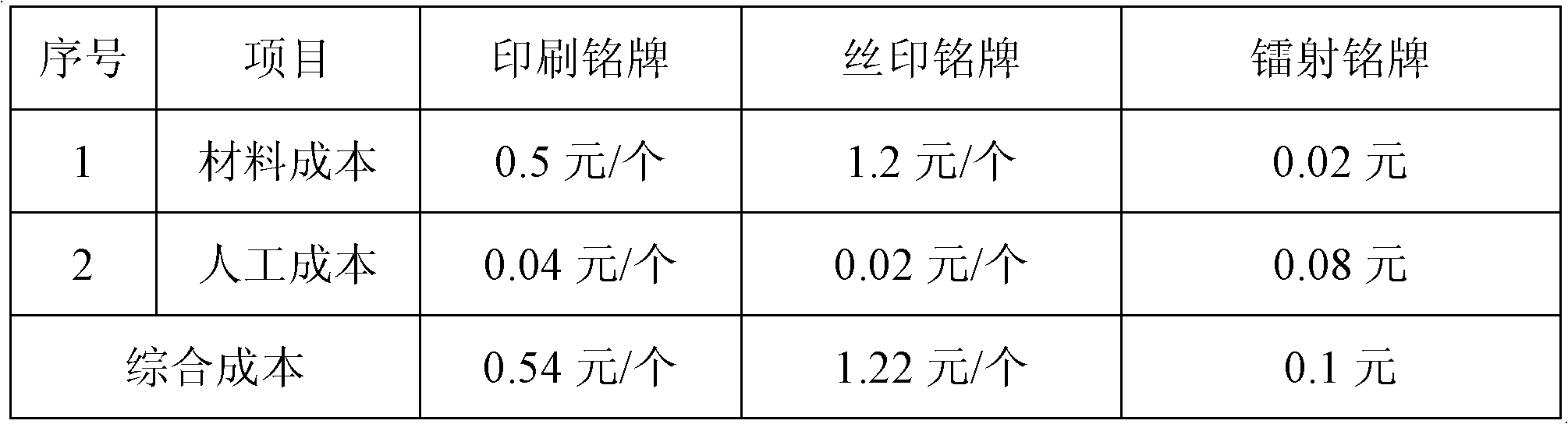

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] This embodiment is a preferred implementation mode of the present invention, and other principles and basic structures that are the same or similar to this embodiment are within the protection scope of the present invention.

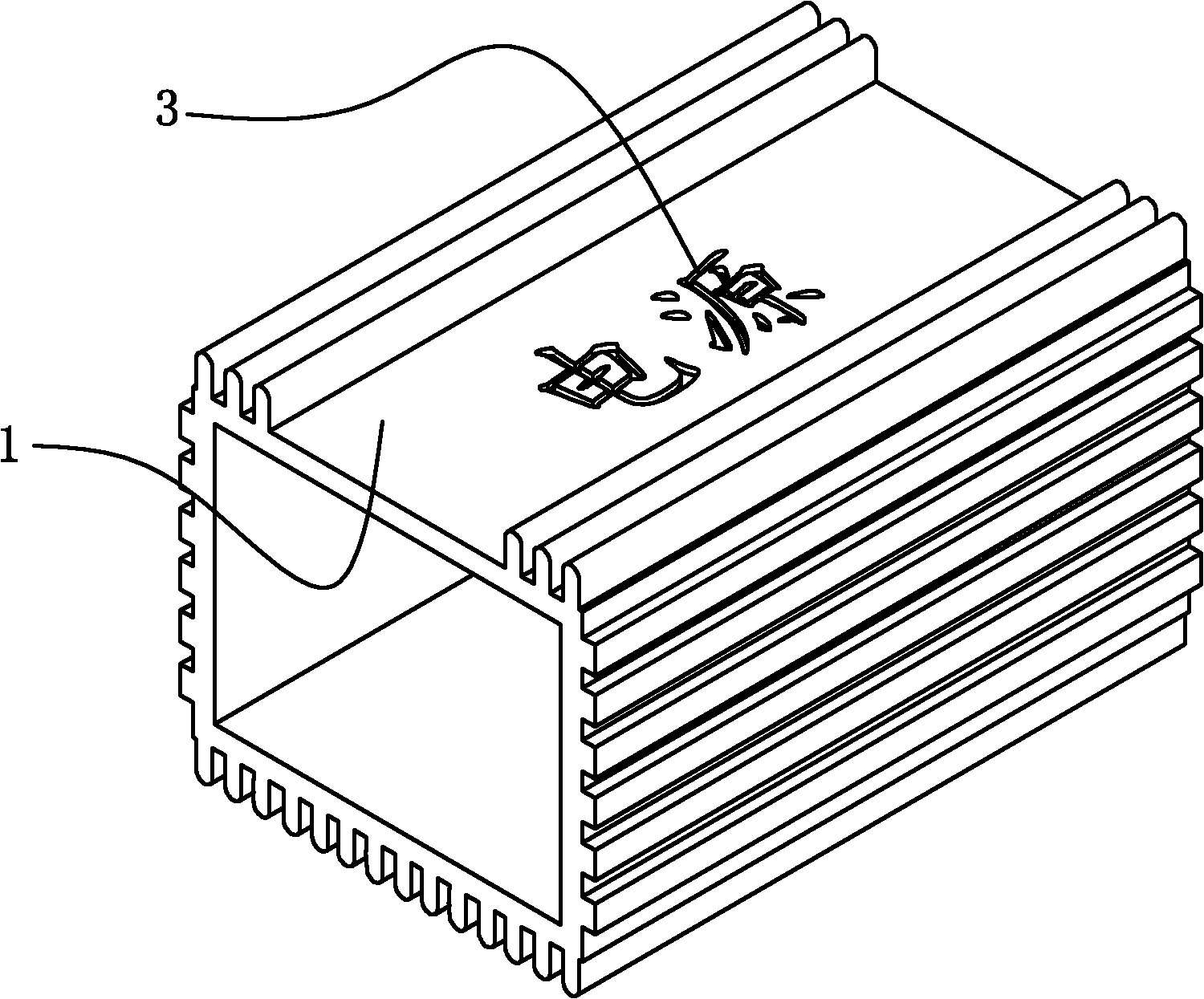

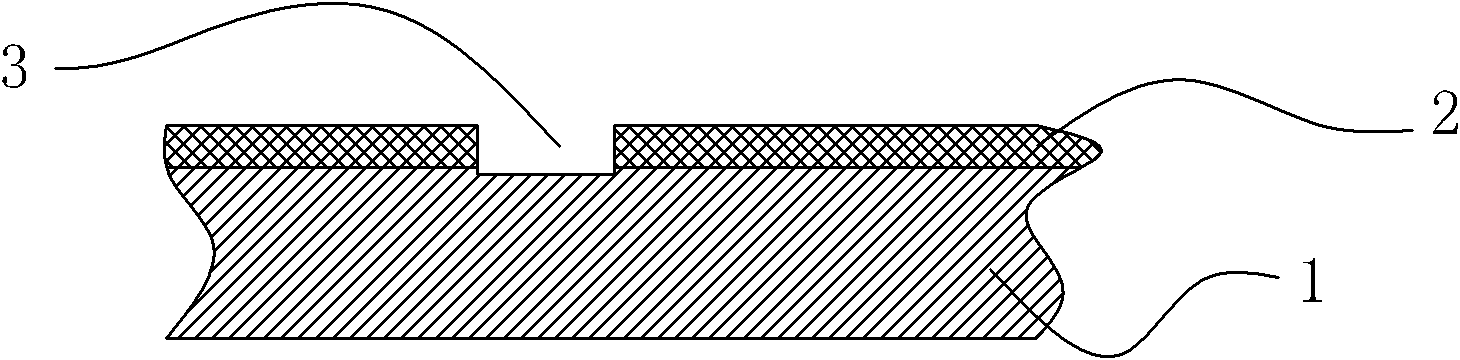

[0023] The present invention uses a laser marking machine to form a nameplate on the metal casing of the power supply by means of laser, which includes the following steps:

[0024] A. Form a layer of film with a color different from that of aluminum on the aluminum casing of the power supply. Since the aluminum casing itself is white, the text pattern formed directly on it by laser laser is not clear enough. In this embodiment, anodic plating is used. A layer of aluminum oxide film is formed on the aluminum casing of the power supply. The usual oxide film is silver gray, and the thickness of the aluminum oxide film is 10μm-18μm. During anodic plating, the plating voltage is 20V-22V, and the plating time is 20min. -40min, in this embodiment, anodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com