Mechanized discharging and concentrating device for small-sized movable sedimentation tank

A settling tank, mobile technology, used in dewatering/drying/concentrating sludge treatment, chemical instruments and methods, cleaning hollow objects, etc. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

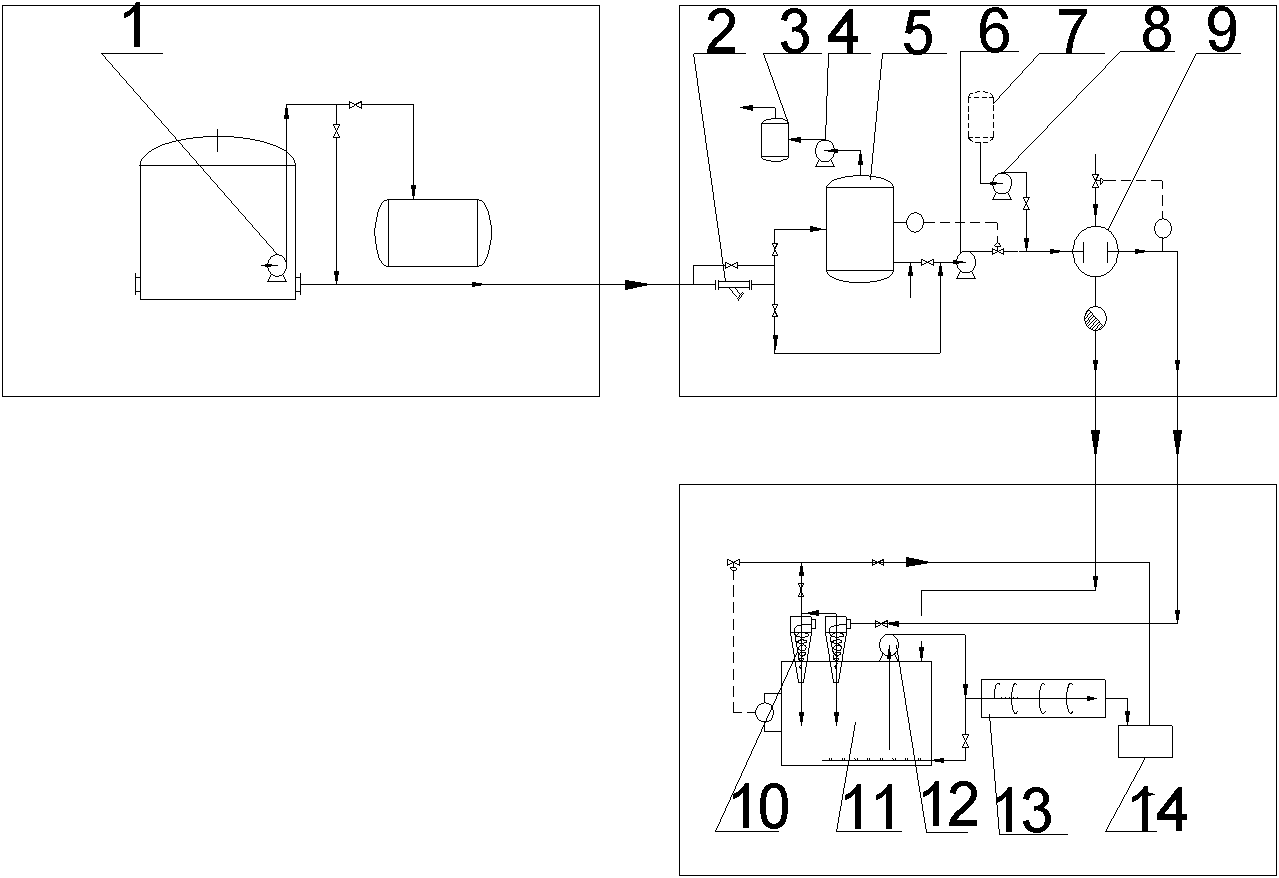

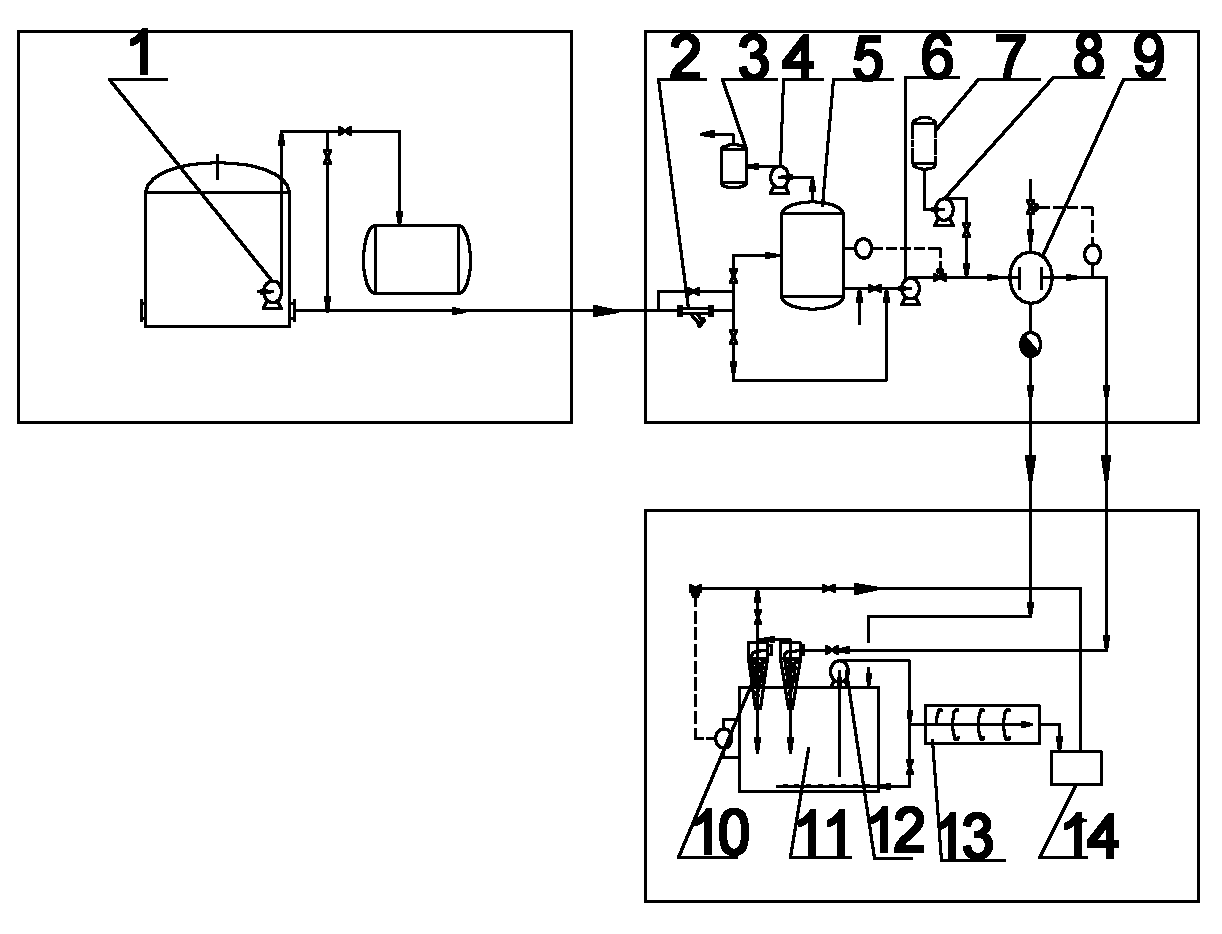

[0016] A small mobile settling tank cleaning and desilting mechanized device is composed of an automatic sludge discharge device A for an oil storage tank and a sludge thickening device B. The device can simultaneously realize the purpose of increasing the capacity of the oil tank by discharging sludge and concentrating the sludge in the tank.

[0017] Its specific structure consists of a submersible submersible pump (1), a filter (2), a gas-liquid separation tank (3), a vacuum pump (4), a vacuum tank (5), a sewage recovery pump (6), a dosing tank (7 ), dosing pump (8), spiral plate heat exchanger (9), cyclone desilter (10), sludge conditioning box (11), sludge lifting pump (12), horizontal centrifuge (13 ), buffer tank (14) and other components.

[0018] The specific connection method is that the outlet of the submersible submersible pump (1) is connected with the oil tank and the inlet of the filter (2), and the outlet of the filter (2) is connected with the vacuum tank (5)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com