Method for preparing carbon nano tube loaded nano nickel powder material by liquid-phase reduction method

A technology of carbon nanotubes and nano-nickel powder, which is applied in the field of preparing carbon nanotube-loaded nano-nickel powder materials, to achieve stable chemical properties, uniform dispersion, and prevent agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

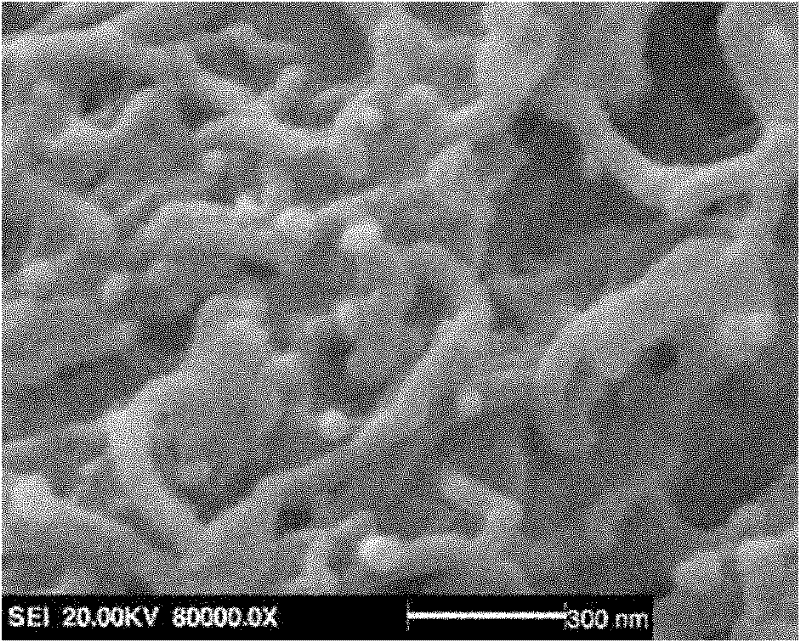

Image

Examples

specific Embodiment approach 1

[0007] Specific embodiment 1: In the present invention, without adding a polymer modifier, a carbon nanotube-loaded nano-nickel powder material with nickel dispersed uniformly on carbon nanotubes and stable chemical properties is obtained by a liquid phase reduction method, and its specific steps as follows:

[0008] Step 1: Acidizing the carbon nanotubes

[0009] Take 1g of carbon nanotubes, add 50-200ml of concentrated nitric acid, reflux and stir at 50-200°C for 1-10 hours, after the acidification is completed, dilute and wash with distilled water until neutral, then vacuum dry at 20-100°C for 12-36 hours Hour;

[0010] Step 2: Acid treatment of carbon nanotube-loaded nano-nickel powder

[0011] First, prepare 0.05~0.5mol / L NiSO 4 ·6H 2 O solution 5-50ml, 0.5-5.0mol / L hydrazine hydrate solution 10-100ml, 0.1-1.0mol / L NaOH solution 5-50ml; secondly, add hydrazine hydrate solution and NaOH solution to NiSO 4 ·6H 2 O solution; finally add 0.1~0.5g acidified carbon nanotu...

specific Embodiment approach 2

[0012] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step one: add the concentrated nitric acid of 70~150ml, reflux and stir at 70~170 ℃ for 1~10 hours, other steps and specific embodiment One is the same.

specific Embodiment approach 3

[0013] Specific embodiment three: the difference between this embodiment and specific embodiment two is: in step one: add the concentrated nitric acid of 80~120ml, reflux and stir at 100~150 ℃ for 2~8 hours, other steps and specific embodiment The first is the same, and the other steps are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com