High-mutual viscosity lustered yellowing-resistance bleached sole rubber and preparation method thereof

A mutual-adhesion and yellowing-resistant technology, applied in shoe soles, footwear, applications, etc., can solve problems such as difficulty in meeting the needs of use, and achieve the effects of simple method, strong pattern retention, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

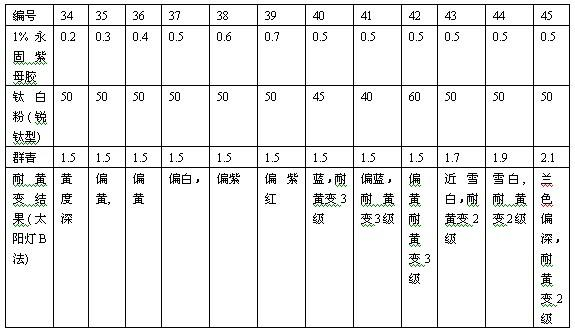

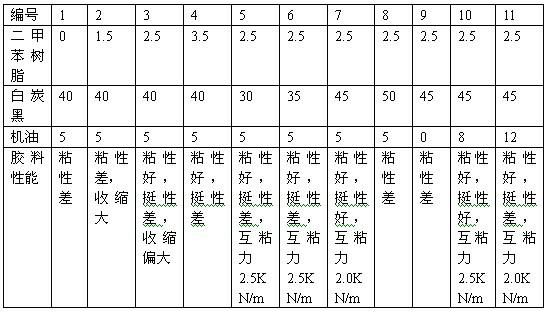

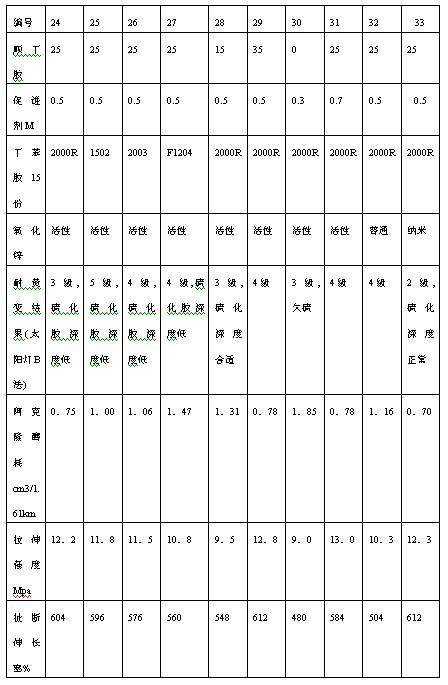

[0043] Embodiment 1 of the present invention: high mutual stickiness luster type anti-yellowing bleaching white shoe sole rubber, calculates by weight, it comprises 65 parts of 1# standard glues, 15 parts of 2000R solution polymerized styrene-butadiene rubbers, 20 parts of butadiene rubbers, 2 parts of sulfur, 2.6 parts of microcrystalline wax, 0.5 parts of accelerator M, 1.9 parts of accelerator DM, 5.6 parts of tertiary stearic acid, 2.5 parts of nano-zinc oxide; 4.3 parts of polyethylene glycol 4000, 1.7 parts of anti-aging agent KY- 405L, 1.9 parts of ultramarine blue, 50 parts of titanium dioxide (R930), 45 parts of white carbon black, 25 parts of nano-calcium carbonate, 0.50 parts of 1% permanent purple mother gum, 8.6 parts of 5# white machine oil and 2.5 parts of RX-80 xylene resin.

[0044] The preparation method of the high mutual-adhesive gloss type anti-yellowing bleaching white shoe sole rubber is characterized in that: plasticizing first, pressing the 1# standard...

Embodiment 2

[0045] Embodiment 2 of the present invention: high mutual stickiness luster type anti-yellowing bleaching white shoe sole rubber, calculates by weight, it comprises 60 parts of 1# standard glues, 20 parts of 2000R solution polymerized styrene-butadiene rubbers, 15 parts of butadiene rubbers, 1 part of sulfur, 2.4 parts of microcrystalline wax, 0.4 parts of accelerator M, 2.0 parts of accelerator DM, 5 parts of tertiary stearic acid, 2 parts of nano-zinc oxide; 4 parts of polyethylene glycol 4000#, 12 parts of anti-aging agent KY -405L, 1.7 parts of ultramarine blue, 55 parts of titanium dioxide (R930), 40 parts of white carbon black, 30 parts of nano calcium carbonate, 0.1 part of 1% permanent purple mother gum, 8 parts of 5# white machine oil and 2 parts of RX-80 toluene resin.

[0046] The preparation method of the high mutual-adhesive gloss type anti-yellowing bleaching white shoe sole rubber is characterized in that: plasticizing first, pressing the 1# standard rubber in t...

Embodiment 3

[0047] Embodiment 3 of the present invention: high mutual tack gloss type anti-yellowing bleaching white shoe sole rubber, is characterized in that: by weight, it comprises 70 parts of 1# standard glue, 10 parts of 2000R solution polystyrene butadiene rubber, 25 parts Butadiene gum, 3 parts of sulfur, 2.8 parts of microcrystalline wax, 0.6 parts of accelerator M, 1.8 parts of accelerator DM, 6 parts of tertiary stearic acid, 3 parts of nano-zinc oxide; 5 parts of polyethylene glycol 4000#, 2 parts 1 part of anti-aging agent KY-405L, 2.1 parts of ultramarine blue, 45 parts of titanium dioxide (R930), 50 parts of white carbon black, 20 parts of nano-calcium carbonate, 0.15 parts of 1% permanent purple mother gum, 9 parts of 5# white machine oil and 2~ 3 parts RX-80 xylene resin.

[0048] The preparation method of the high mutual-adhesive gloss type anti-yellowing bleaching white shoe sole rubber is characterized in that: plasticating first, pressing the 1# standard rubber in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com