Epoxy resin base layer treating agent used for spraying polyurea and preparation method thereof

A base treatment agent and epoxy resin technology, applied in epoxy resin coatings, coatings, etc., can solve the problems of polyurea and concrete bonding attenuation, difficult bonding of polyurea waterproof layer, failure of polyurea waterproof layer, etc. , to achieve the effect of improving adhesion, easy control of product quality and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

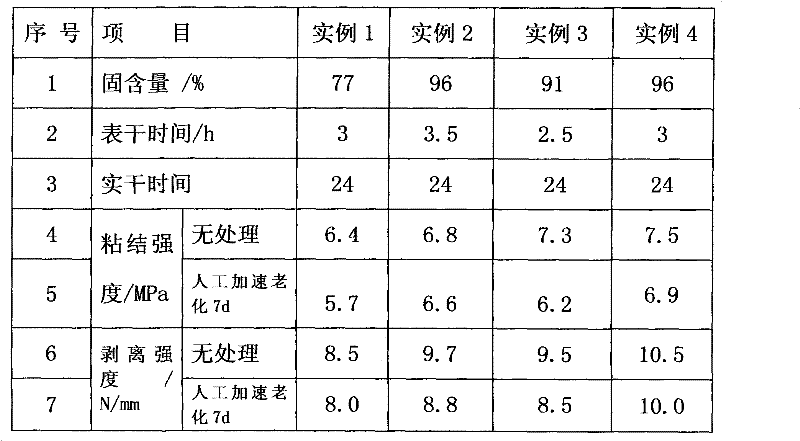

Examples

Embodiment 1

[0049] 1. Formula of two-component epoxy resin base treatment agent

[0050] The weight ratio of component A is:

[0051] Liquid Bisphenol A Epoxy Resin E-51 Wuxi Resin Factory 30g

[0052] Liquid Bisphenol A Epoxy Resin E-44 Wuxi Resin Factory 30g

[0053] Reactive diluent 501 Wuxi Resin Factory 5g

[0054] Leveling agent BYK-310 BYK Chemie 0.5g

[0055] Defoamer BYK-066 BYK Chemie 0.5g

[0056] Xylene Industrial Grade 24g

[0057] Butanol technical grade 9g

[0058] The weight ratio of component B is:

[0059] Modified amine curing agent 593 Miki Chemical Industry 10g

[0060] Toughening (curing) agent 650 Miki Chemical 15g

[0061] Accelerator DMP-30 Miki Chemical Industry 1g

[0062] Coupling agent KH-550 Jiangsu Chenguang 1g

[0063] Xylene Industrial grade 3g

[0064] Butanol technical grade 3g

[0065] 2. Preparation process of two-component epoxy resin base treatment agent

[0066] (1) Preparation of component A

[0067] First add the epoxy resin into the...

Embodiment 2

[0072] 1. Formula of multi-component epoxy resin base treatment agent

[0073] The weight ratio of component A is:

[0074] Liquid Bisphenol A Epoxy Resin E-51 Wuxi Resin Factory 30g

[0075] Liquid Bisphenol A Epoxy Resin E-44 Wuxi Resin Factory 30g

[0076] Reactive diluent 501 Wuxi Resin Factory 5g

[0077] Leveling agent BYK-310 BYK Chemie 0.5g

[0078] Defoamer BYK-066 BYK Chemie 0.5g

[0079] Xylene Industrial grade 3g

[0080] Butanol technical grade 1g

[0081] The weight ratio of component B is:

[0082] Modified amine curing agent 593 Miki Chemical Industry 10g

[0083] Toughening (curing) agent 650 Miki Chemical 15g

[0084] Accelerator DMP-30 Miki Chemical Industry 1g

[0085] Coupling agent KH-550 Jiangsu Chenguang 1g

[0086] Xylene industrial grade 2g

[0087] Butanol technical grade 1g

[0088] The weight ratio of component C:

[0089] Quartz sand (80 mesh) industrial grade 70g

[0090] Cement (PO42.5) Industrial Grade 30g

[0091] 2. Preparation...

Embodiment 3

[0100] 1. Formula of two-component epoxy resin base treatment agent

[0101] The weight ratio of component A is:

[0102] Liquid bisphenol A epoxy resin CYD-127 Baling Petrochemical Epoxy Resin Factory 80g

[0103] Reactive diluent 692 Wuxi Resin Factory 10g

[0104] Leveling agent BYK-310 BYK Chemie 0.5g

[0105] Defoamer BYK-066 BYK Chemie 0.5g

[0106] Xylene industrial grade 6g

[0107] Butanol technical grade 2g

[0108] The weight ratio of component B is:

[0109] Modified amine curing agent 593 Miki Chemical Industry 10g

[0110] Modified amine curing agent T-31 Miki Chemical Industry 10g

[0111] Toughening (curing) agent 650 Miki Chemical 10g

[0112] Accelerator DMP-30 Miki Chemical Industry 2g

[0113] Coupling agent Jiangsu Chenguang 1g

[0114] Preparation process is identical with example 1.

[0115] When in use, component A and component B are mixed in a weight ratio of component A: component B = 3:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com