Preparation method of Sn-doped ZnO nanocrystalline

A nanocrystal and tin doping technology, applied in the field of preparation of ZnO nanocrystals, can solve the problem of high calcination temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: Accurately weigh 4.4g Zn(NO 3 ) 2 ·6H 2 O, 0.053gSnCl 4 ·5H 2 O and 4.0 g NaOH. These three reagents were added to a ball mill, and ball milled for 10 minutes. Add 1.53 g of cationic surfactant cetyltrimethylammonium bromide and continue ball milling for 50 minutes. Before the material was dried, the material was washed with deionized water and absolute ethanol until no impurity ions existed. The obtained white powder was dried at 60° C. for 10 h in a blast drying oven. After drying and grinding to obtain a fine white powder, the fine white powder was calcined in a muffle furnace at 500° C. for 3 hours to obtain tin-doped ZnO nanocrystals.

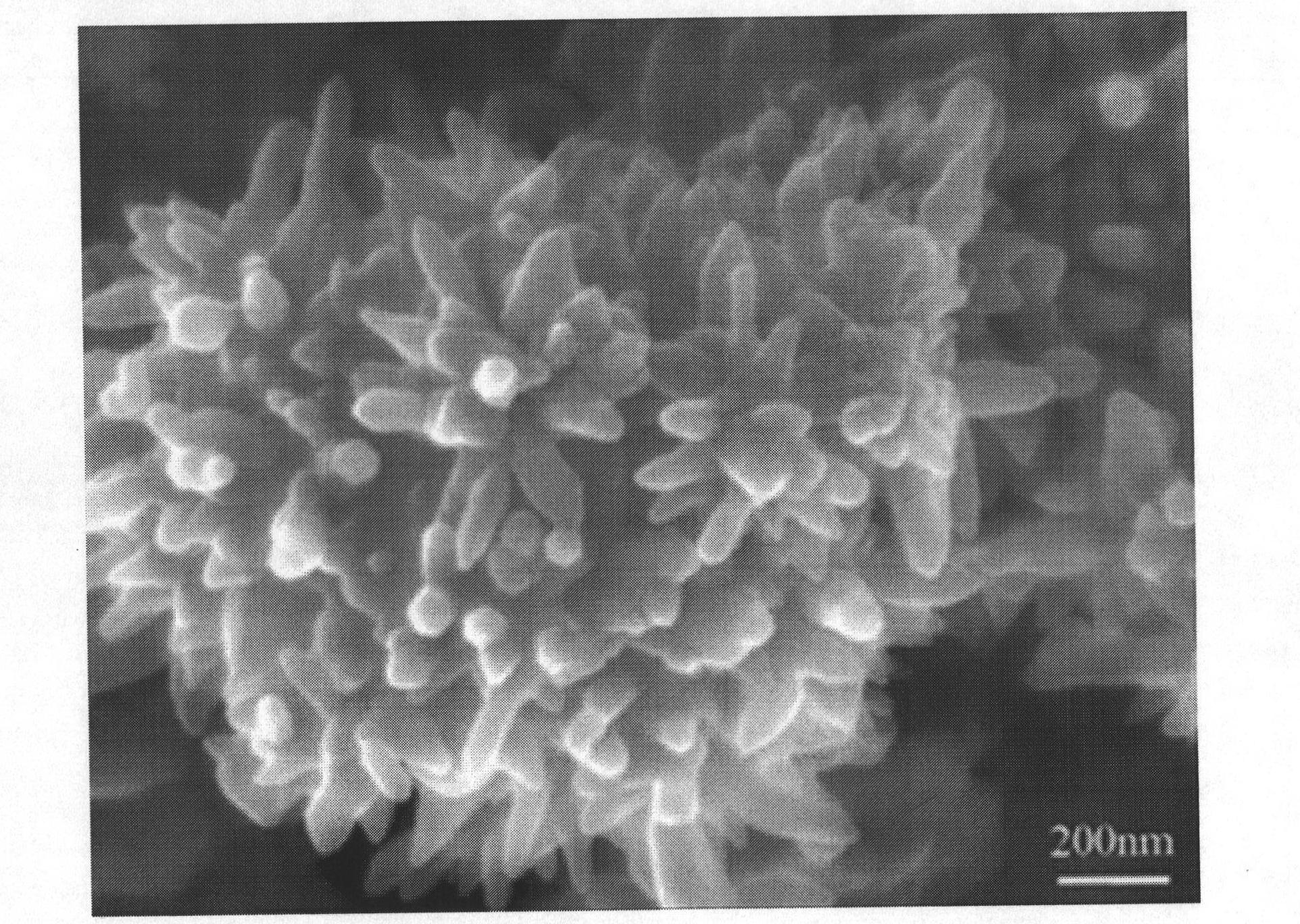

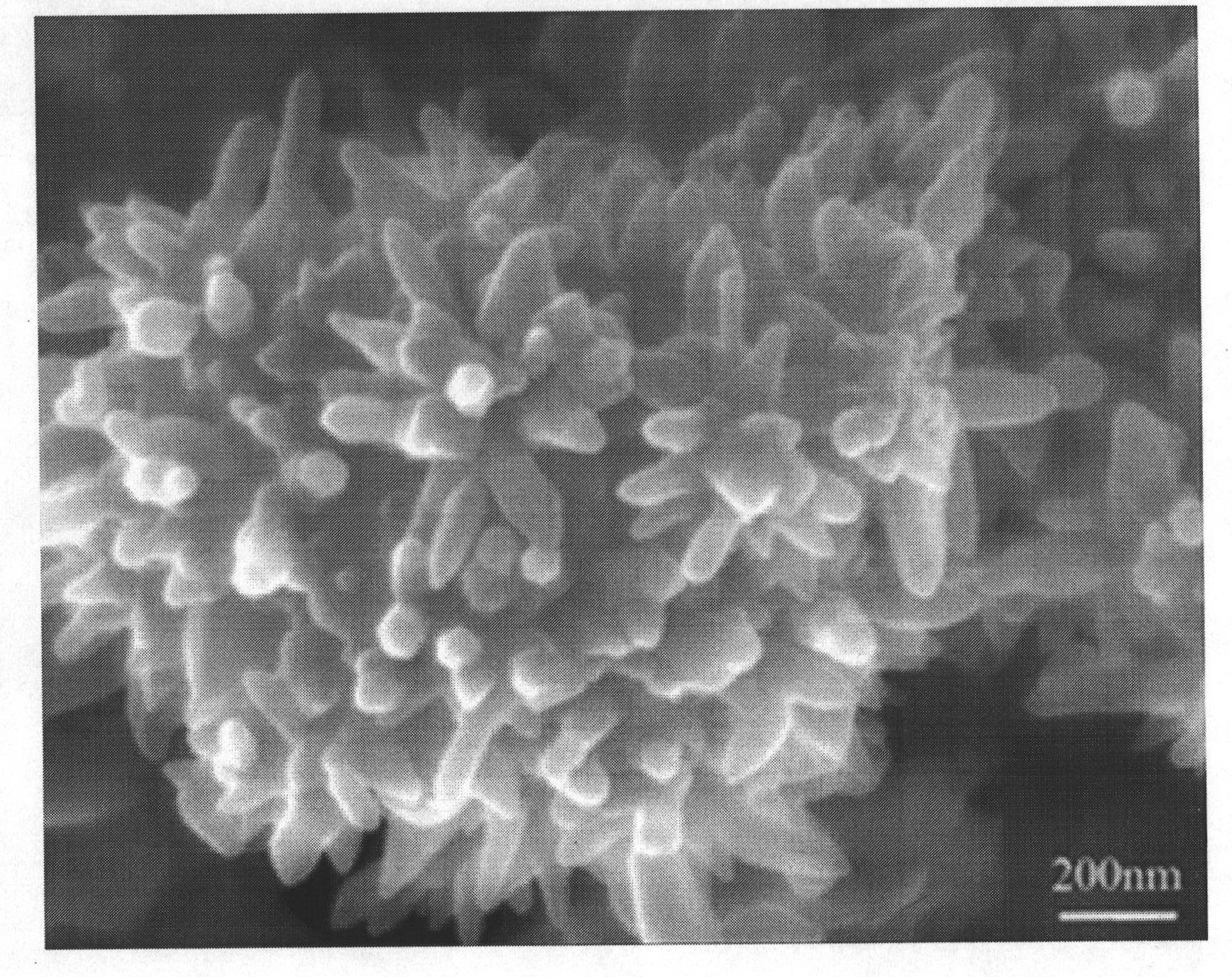

[0016] from figure 1 It can be seen that the surface of the tin-doped ZnO nanocrystal prepared in Example 1 is assembled by short nanorods to form a spherical product similar to a hedgehog.

Embodiment 2

[0017] Embodiment 2: Accurately weigh 4.46g Zn(NO 3 ) 2 ·6H 2 O, 0.159g SnCl 4 ·5H 2 O and 4.2g NaOH. These three reagents were added into a ball mill, and ball milled and mixed for 12 minutes. Add 1.536 g of cationic surfactant cetyltrimethylammonium bromide and continue ball milling for 48 minutes. Before the material was dried, the material was washed with deionized water and absolute ethanol until no impurity ions existed. The obtained white powder was dried at 63° C. for 9 h in a blast drying oven. After drying, it was ground to obtain a fine white powder, which was calcined in a muffle furnace at 530° C. for 2.7 hours to obtain tin-doped ZnO nanocrystals.

Embodiment 3

[0018] Embodiment 3: Accurately weigh 4.48g Zn(NO 3 ) 2 ·6H 2 O, 0.465g SnCl 4 ·5H 2 O and 4.4g NaOH. These three reagents were added into a ball mill, and ball milled and mixed for 14 minutes. Add 1.538 g of cationic surfactant cetyltrimethylammonium bromide and continue ball milling for 46 minutes. Before the material was dried, the material was washed with deionized water and absolute ethanol until no impurity ions existed. The obtained white powder was dried at 66° C. for 9 h in a blast drying oven. After drying and grinding, a fine white powder was obtained, which was calcined in a muffle furnace at 560° C. for 2.3 hours to obtain tin-doped ZnO nanocrystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com