System and method for detecting leakage of high-temperature gas in high-temperature high-pressure guide pipe of airplane

A high-temperature, high-pressure, and high-temperature gas technology, applied in the field of high-temperature gas leakage detection systems, can solve problems such as false alarms on the insulation layer, complicated lines, and difficulty in judging leakage, and achieve the effects of ensuring flight safety, improving dispatch rates, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

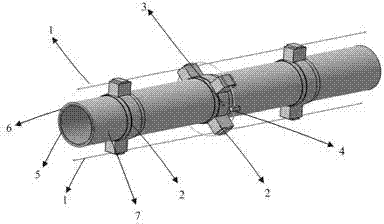

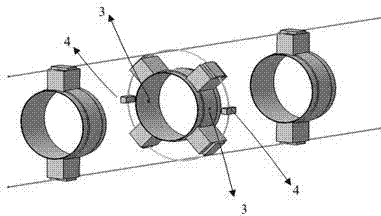

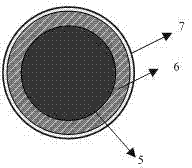

[0021] according to figure 1 As shown, the aircraft high-temperature gas conduit leakage detection system and method of the present invention are composed of two axial thermistor detection lines 1 , a wire mounting frame 2 , a diversion hole 3 and a temperature trigger 4 . The thermistor detection line 1 is divided into several detection units by using the lead mounting frame 2 . Each measuring unit is composed of a section of axial wire of line AB and a section of axial wire of line CD, and a circumferential thermistor detection loop connected in series between the sections. Each measuring unit is responsible for monitoring an area.

[0022] The thermal thermistor wire in the measurement unit has a high temperature coefficient of resistance. According to the relationship between resistance and temperature, it is divided into a positive temperature system thermistor and a negative temperature coefficient thermistor. The resistance of the former increases sharply with the incr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com