Catalyst for using C4 olefin to prepare ethylene and propylene by catalytic pyrolysis and application method thereof

A catalytic cracking and ethylene propylene technology, which is applied in the direction of carbon compound catalysts, physical/chemical process catalysts, catalysts, etc., can solve the problems of low ethylene propylene yield and poor thermal stability of catalysts, and achieve high hydrothermal stability and high temperature water Thermal stability, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

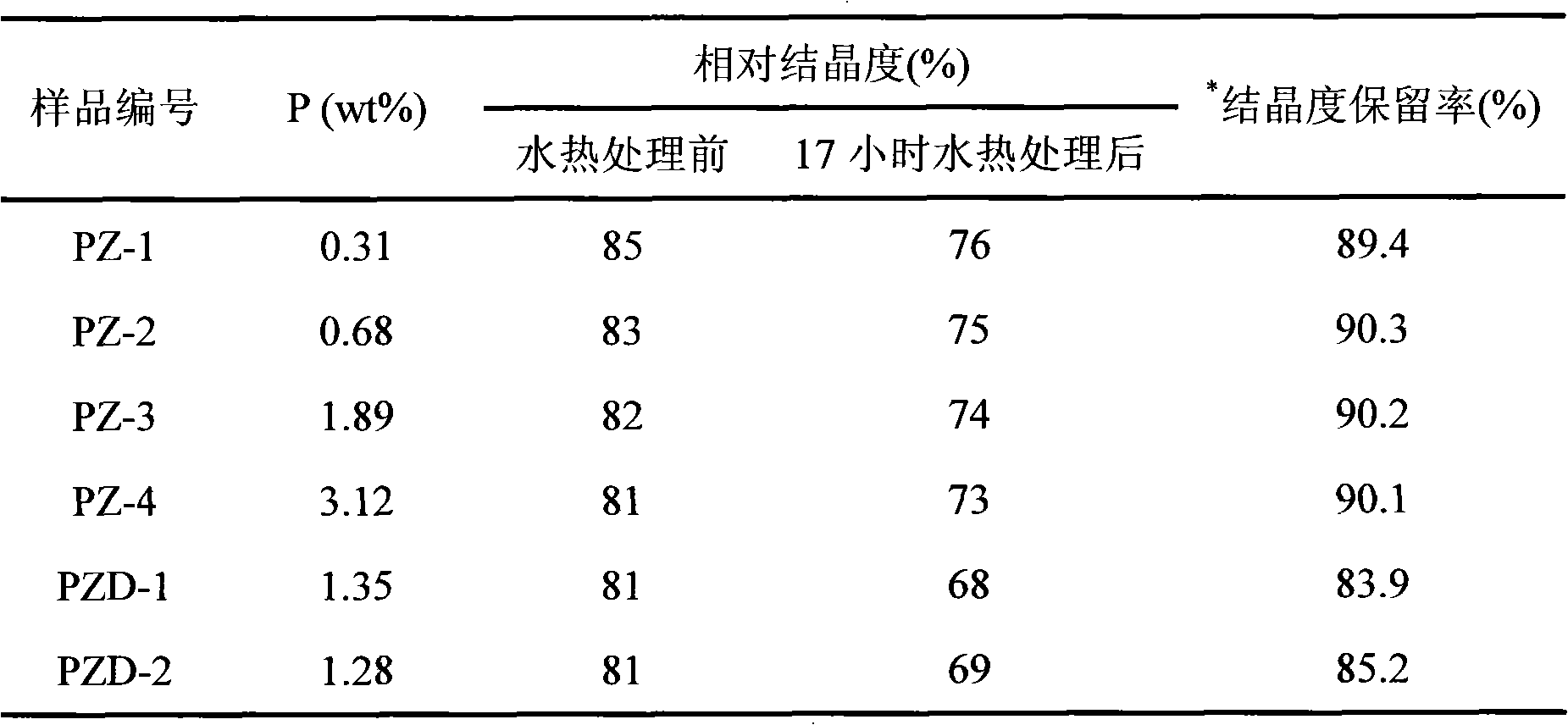

[0036] Take 23.3 grams (NH 4 ) 2 HPO 4 Dissolve in 1000 grams of distilled water, add 270 grams of ZSM-5 molecular sieve sample to the solution with stirring, and adjust the pH to 4. At a reaction temperature of 100°C and a reaction pressure of 0.2MPa, the reaction was stirred for 60 minutes, filtered, dried, and then calcined at 500°C for 4 hours. The resulting molecular sieve sample was designated as PZ-1. The composition of the sample and the crystallinity before and after aging are shown in Table 1.

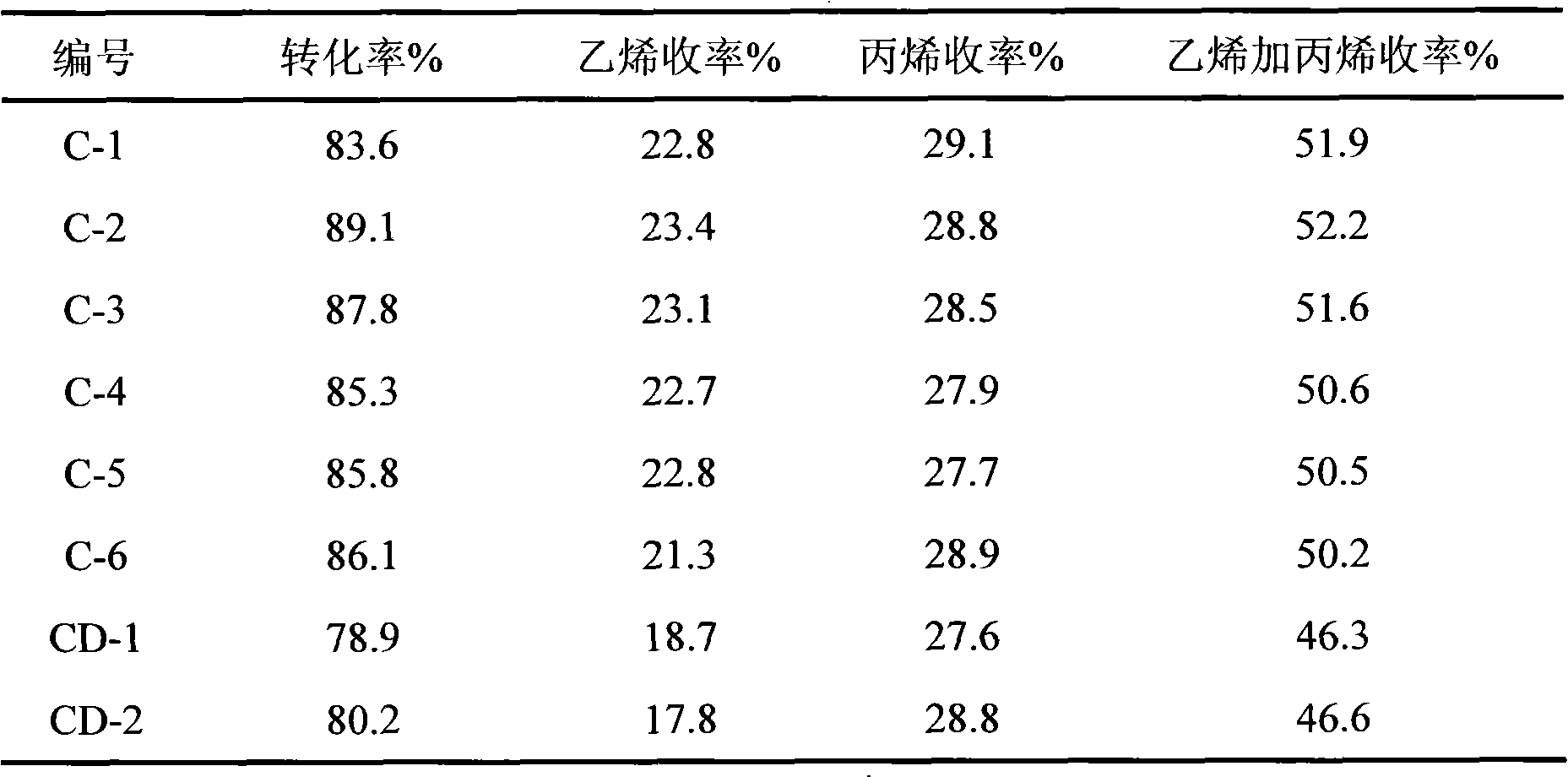

[0037] The catalyst is prepared by the tablet method, and the PZ-1 and α-Al 2 O 3 After the carrier is evenly mixed, use a tablet press to press tablets at 20MPa, PZ-1 and Al 2 O 3 The carrier weight ratio is 90:10, and 20-40 mesh particles are taken. The catalyst is designated as C-1.

[0038] Reaction conditions: take heavy carbon four in the east zone of Lanzhou Petrochemical Company as raw material, water / carbon four olefin volume ratio is 0.01, weight hourly space velocity i...

Embodiment 2

[0040] Take 69.7 grams (NH 4 )H 2 PO 4 Dissolve in 1000 grams of distilled water, add 270 grams of ZSM-11 molecular sieve sample to the solution with stirring, and adjust the pH to 2. At a reaction temperature of 140°C and a reaction pressure of 0.6 MPa, the reaction was stirred for 200 minutes, filtered, dried, and then calcined at 450°C for 6 hours. The resulting molecular sieve sample was designated as PZ-2. The composition of the sample and the crystallinity before and after aging are shown in Table 1.

[0041] The catalyst is prepared by extrusion method, PZ-2 and β-Al 2 O 3 The carrier weight ratio is 90:10, and the catalyst is extruded into a strip shape. The catalyst is designated as C-2.

[0042] Reaction conditions: Taking heavy carbon four in the east zone of Lanzhou Petrochemical Company as raw material, water / carbon four olefin volume ratio of 0.1, weight hourly space velocity of 3h -1 , The reaction temperature is 450°C, and the reaction pressure is 0.1 MPa. The cat...

Embodiment 3

[0044] Take 70 grams (NH 4 ) 2 HPO 4 And 69.4 grams (NH 4 )H 2 PO 4 The mixture was dissolved in 1000 grams of distilled water, 270 grams of ZSM-18 molecular sieve sample was added to the solution under stirring, and the pH value was adjusted to 3. At a reaction temperature of 160°C and a reaction pressure of 0.8MPa, the reaction was stirred for 200 minutes, filtered, dried, and then calcined at 550°C for 4 hours. The resulting molecular sieve sample was designated as PZ-3. The composition of the sample and the crystallinity before and after aging are shown in Table 1.

[0045] The catalyst is prepared by extrusion method, PZ-3 and γ-Al 2 O 3 The carrier weight ratio is 70:30, and the catalyst is extruded into a strip shape. The catalyst is designated as C-3.

[0046] Reaction conditions: take the mixed carbon four in the east zone of Lanzhou Petrochemical Company as raw material, the volume ratio of water / carbon four olefin is 0.6, and the weight hourly space velocity is 6h -1 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com