LiZn ferrite material for Ka-band phase shifter and preparation method thereof

A technology for ferrite materials and phase shifters, which is applied in the field of LiZn ferrite materials and preparations for Ka-band phase shifters, can solve the problems of increased dielectric loss, composition segregation, low coercive force, etc., and achieve low ferromagnetism Effects of Resonant Linewidth, High Saturation Magnetization, and Low Dielectric Loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

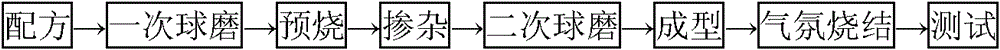

Method used

Image

Examples

Embodiment 1

[0033] 1) Main formula: with Li 0.35+x Zn 0.3 Fe 2.28 mn 0.07 o 4+δ Molecular formula calculation, x=0.05, x=2δ; main material is Fe 2 o 3 , ZnO, Li 2 CO 3 , Mn 3 o 4 ;

[0034] 2) Primary ball milling: mill the raw materials used in step 1) in a ball mill for 2 hours to make the powder mix evenly;

[0035] 3) Pre-burning: Pre-burning the ball abrasive obtained in step 2) in a furnace at 810°C for 2 hours;

[0036] 4) Doping: Add additive 1.2wt% Bi to the powder obtained in step 3) by weight 2 o 3 , 0.4wt% NiO, 0.2wt% V 2 o 5 , milling the powder in a planetary ball mill for 3 hours;

[0037] 5) molding: adding 15wt% organic binder to the powder obtained in step 4) according to the weight ratio, mixing evenly, and after granulating, pressing the granular powder into a blank on a press;

[0038] 6) Atmosphere sintering: the blank obtained in step 5) was sintered in an atmosphere sintering furnace at a temperature of 1000° C. for 3 hours in an oxygen atmosphere. ...

Embodiment 2

[0049] 1) with Li 0.35+x Zn 0.3 Fe 2.28 mn 0.07 o 4+δ Molecular formula calculation, x=0.10, x=2δ; main material is Fe 2 o 3 , ZnO, Li 2 CO 3 , Mn 3 o 4 ;

[0050] 2) Primary ball milling: mill the raw materials used in step 1) in a ball mill for 2 hours to make the powder mix evenly;

[0051] 3) Pre-burning: Pre-burning the ball abrasive obtained in step 2) in a furnace at 810°C for 2 hours;

[0052] 4) Doping: Add additive 1.0wt% Bi to the powder obtained in step 3) by weight 2 o 3 , 0.3wt% NiO, 0.3wt% V 2 o 5 , milling the powder in a planetary ball mill for 3 hours;

[0053] 5) molding: adding 15wt% organic binder to the powder obtained in step 4) according to the weight ratio, mixing evenly, and after granulating, pressing the granular powder into a blank on a press;

[0054] 6) Atmosphere sintering: the blank obtained in step 5) was sintered at 1030° C. for 2.5 hours in an atmosphere sintering furnace in an oxygen atmosphere.

[0055] The LiZn ferrite ma...

Embodiment 3

[0065] 1) with Li 0.35+x Zn 0.3 Fe 2.28 mn 0.07 o 4+δ Molecular formula calculation, x=0.15, x=2δ; main material is Fe 2 o 3 , ZnO, Li 2 CO 3 , Mn 3 o 4 ;

[0066] 2) Primary ball milling: mill the raw materials used in step 1) in a ball mill for 2 hours to make the powder mix evenly;

[0067] 3) Pre-burning: Pre-burning the ball abrasive obtained in step 2) in a furnace at 810°C for 2 hours;

[0068] 4) Doping: Add additive 1.2wt% Bi to the powder obtained in step 3) by weight 2 o 3 , 0.3wt% NiO, 0.25wt% V 2 o 5 , milling the powder in a planetary ball mill for 3 hours;

[0069]5) molding: adding 15wt% organic binder to the powder obtained in step 4) according to the weight ratio, mixing evenly, and after granulating, pressing the granular powder into a blank on a press;

[0070] 6) Atmosphere sintering: the blank obtained in step 5) is sintered in an atmosphere sintering furnace at a temperature of 1000° C. for 2 hours in an oxygen atmosphere.

[0071] The L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com