Technology for extracting amino acids from residual medicine dregs generated in production of erythromycin

A technology of erythromycin and amino acids, which is applied in the direction of sugar derivatives, sugar derivatives, sugar derivatives preparation, etc., can solve the problems of resource waste, environmental pollution, and failure to meet national requirements, and achieve the effect of solving pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

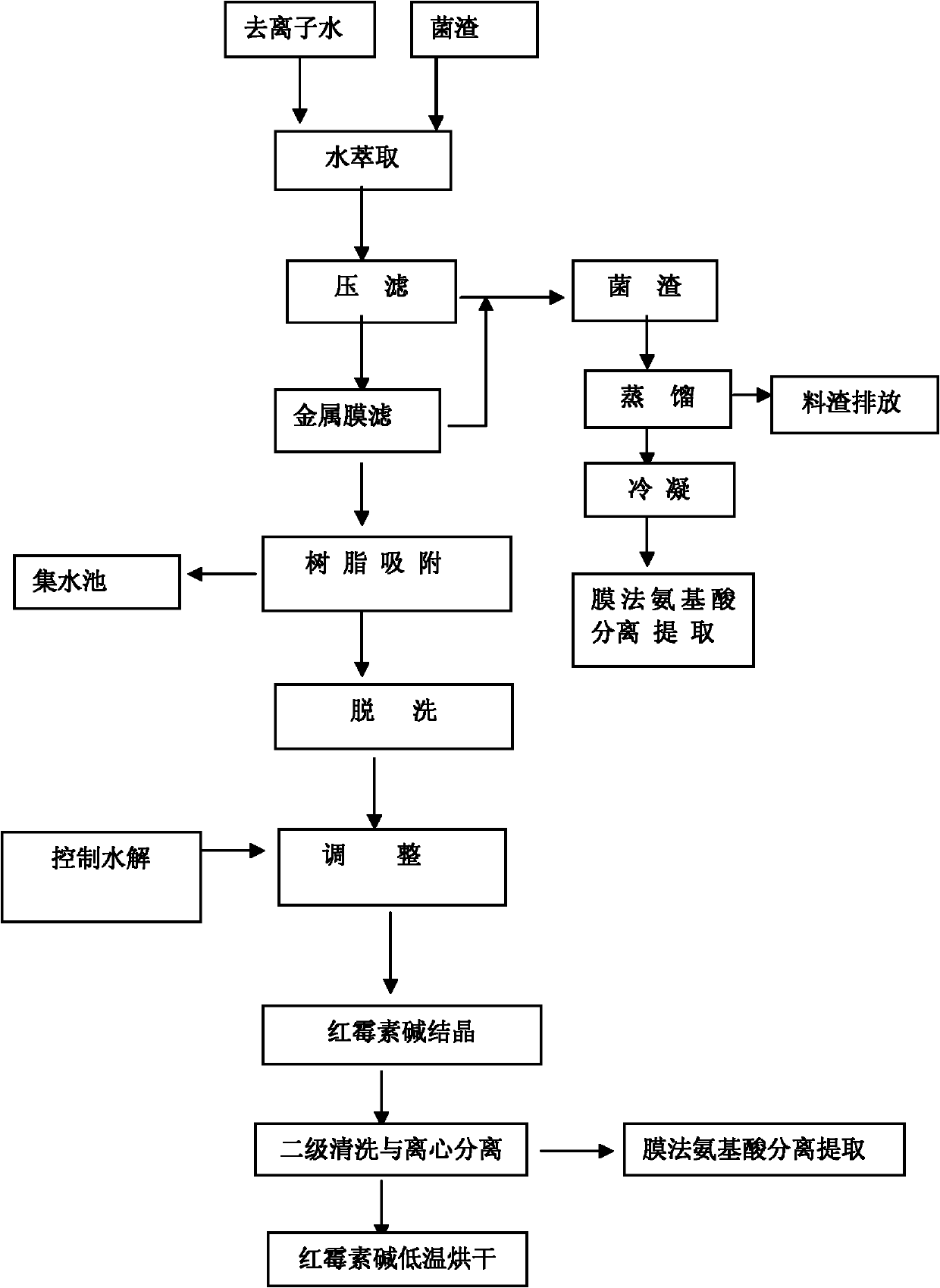

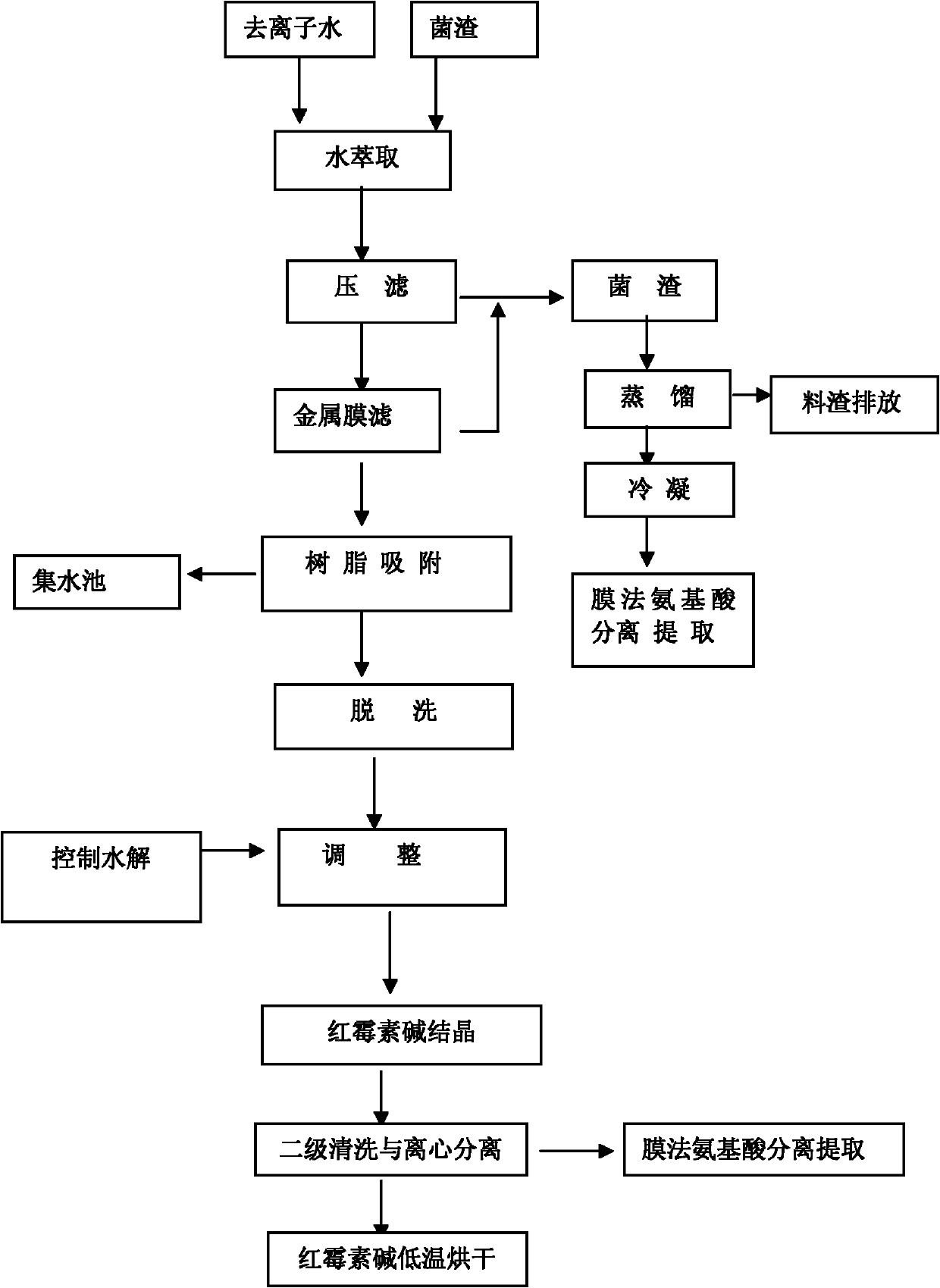

[0017] A kind of technology for extracting amino acid from erythromycin residual dregs, carried out according to the following steps:

[0018] a. Adjust the pH of 1000 tons (in terms of dry matter) of the residual medicinal residues produced by fermentation of erythromycin to 8, extract with deionized water under normal pressure, control the stirring speed to be 220rpm, and press filter under 20-35Mpa;

[0019] b. Distill the solids obtained by pressure filtration at 180-190°C at a low temperature, and the gas generated by the distillation is condensed and then separated and extracted by membrane method to extract amino acids; the separation and extraction of amino acids by membrane method is carried out under the condition of 0.2-0.3 MPa;

[0020] c. The filtrate obtained by pressure filtration is first filtered through titanium membrane or stainless steel membrane, and the solid obtained by metal membrane filtration is mixed with the solid obtained by press filtration to carr...

Embodiment 2

[0023] A kind of technology for extracting amino acid from erythromycin residual dregs, carried out according to the following steps:

[0024] a. Adjust the pH of 1000 tons (calculated as dry matter) of the residue of erythromycin by fermentation to 9, extract with deionized water under normal pressure, control the stirring speed to be 290rpm, and press filter under 2~17Mpa;

[0025] b. Distilling the solids obtained by pressure filtration at a low temperature of 165-170° C., and the gas generated by the distillation is condensed and then separated and extracted by a membrane method to extract amino acids; the separation and extraction of amino acids by the membrane method is carried out under the condition of 0.1-0.2 MPa;

[0026] c. The filtrate obtained by pressure filtration is first filtered through titanium membrane or stainless steel membrane, and the solid obtained by metal membrane filtration is mixed with the solid obtained by press filtration to carry out the treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com