Fluorine-containing easily processed acrylate rubber and preparation method thereof

A technology of acrylate and ethyl acrylate, which is applied in the field of fluorine-containing easy-to-process acrylate rubber and its preparation, can solve the problems of expensive external mold release agent, corrosion of containers, easy to leave mold scale, etc., and achieve good durability High temperature performance, good processing performance, and the effect of improving processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

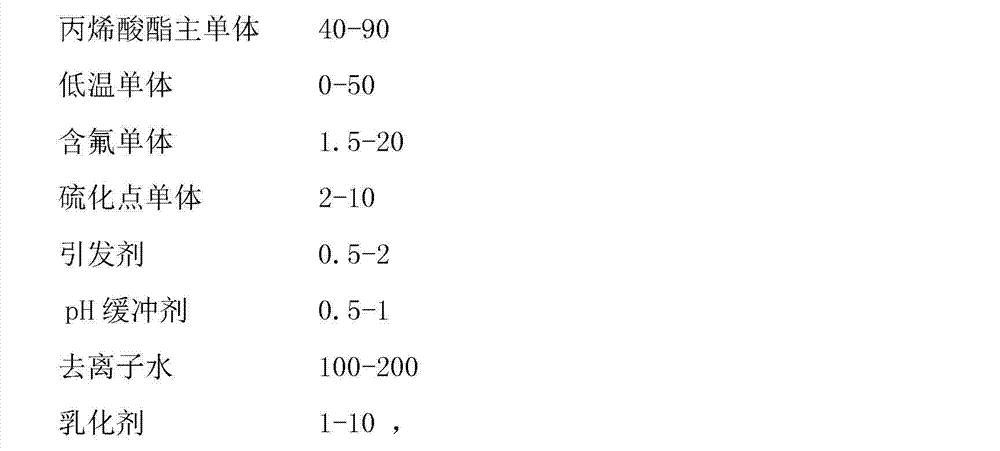

Method used

Image

Examples

Embodiment 1

[0029] Example 1 10g methyl acrylate, 80g ethyl acrylate, 5g hexafluorobutyl acrylate, 5g vinyl chloroacetate, 1g potassium persulfate, 1g ammonium bicarbonate, 200g deionized water, 2g sodium lauryl sulfate, 4g OP-10.

[0030] First, add 2g sodium lauryl sulfate, 4g OP-10, and part of deionized water into the emulsification tank and stir to dissolve; then add 10g methyl acrylate, 80g ethyl acrylate, 5g hexafluorobutyl acrylate, 5g vinyl chloroacetate After the ester is mixed, add 1 / 3 of it to the emulsification tank and emulsify it at high speed for 30 minutes under the protection of nitrogen to form an emulsion; then add 1g potassium persulfate, 1g ammonium bicarbonate and part of deionized water into the mixing tank and stir to dissolve ; The emulsified emulsion and 1 / 3 of the initiator system solution were transferred to the reactor in turn, and the polymerization reaction was initiated at 65°C. During the reaction, the temperature was controlled at 65°C-70°C, and the remain...

Embodiment 2

[0032] Example 2 Methyl acrylate 10g, ethyl acrylate 75g, dodecafluoroheptyl acrylate 10g, vinyl chloroacetate 5g, potassium persulfate 1g, ammonium bicarbonate 1g, deionized water 150g, sodium lauryl sulfate 2g, OP-10 4g.

[0033] First add sodium lauryl sulfate, OP-10 and part of deionized water into the emulsification tank and stir to dissolve; then mix acrylate monomer, fluorine-containing monomer, and vulcanization point monomer, and add 1 / 3 to In the emulsification tank, emulsify at high speed for 30 minutes under the protection of nitrogen to form an emulsion; then add the initiator potassium persulfate, pH buffer ammonium bicarbonate and deionized water into the mixing tank and stir to dissolve; add the emulsified emulsion and 1 / 3 initiator system solution was transferred to the reactor in turn, and the polymerization reaction was initiated at 65℃. During the reaction, the temperature was controlled at 65℃-70℃, and the remaining monomer and initiator system were added dr...

Embodiment 3

[0035] Example 3 Ethyl acrylate 60g, butyl acrylate 30g, dodecafluoroheptyl acrylate 5g, vinyl chloroacetate 5g, potassium persulfate 1g, ammonium bicarbonate 1g, deionized water 150g, sodium dodecylbenzene sulfonate 1 part, OP-10 2g, polyoxyethylene cetyl ether 2g.

[0036] First add sodium lauryl sulfate, OP-10, polyoxyethylene cetyl ether and deionized water into the emulsification tank and stir to dissolve; then add the acrylate monomer, low temperature monomer, fluorine-containing monomer, vulcanized After the monomer is mixed, add 1 / 2 into the emulsification tank and emulsify at high speed for 30 minutes under the protection of nitrogen; then add the initiator potassium persulfate, pH buffer ammonium bicarbonate and deionized water to the mixing tank and stir to dissolve ; The emulsified emulsion and 1 / 2 initiator system solution were transferred to the reactor in turn, and the polymerization reaction was initiated at 65°C. During the reaction, the temperature was controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com