Liquid crystal alignment agent, liquid crystal alignment film and liquid crystal display element

A liquid crystal alignment agent and liquid crystal alignment technology, applied in liquid crystal materials, instruments, optics, etc., can solve the problems of decreased brightness or contrast, inversion of brightness, and narrow viewing angle of visual images, and achieve improved black level and good alignment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0142] Hereinafter, the present invention will be explained through examples and comparative examples.

[0143] The evaluation method of the liquid crystal display element in the example is as follows.

[0144]

[0145] It is determined using an ellipsometer M-2000U (manufactured by J.A. Woollam Co. Inc.). In the case of this example, the retardation value of the film increases in proportion to the degree of alignment of the polymer main chain. That is, a film with a large retardation value has a large degree of alignment.

[0146]

[0147] Use the method described in "Mizushima, the 14th Liquid Crystal Seminar Preliminary Collection p78 (1988)". The measurement was performed by applying a rectangular wave with a wave height of ±5V to the liquid crystal cell. The measurement is performed at 60°C. This value is an index indicating how much the applied voltage is maintained after the frame period. If the value is 100%, it means that all electric charges are maintained.

[0148]

[0...

Synthetic example 1

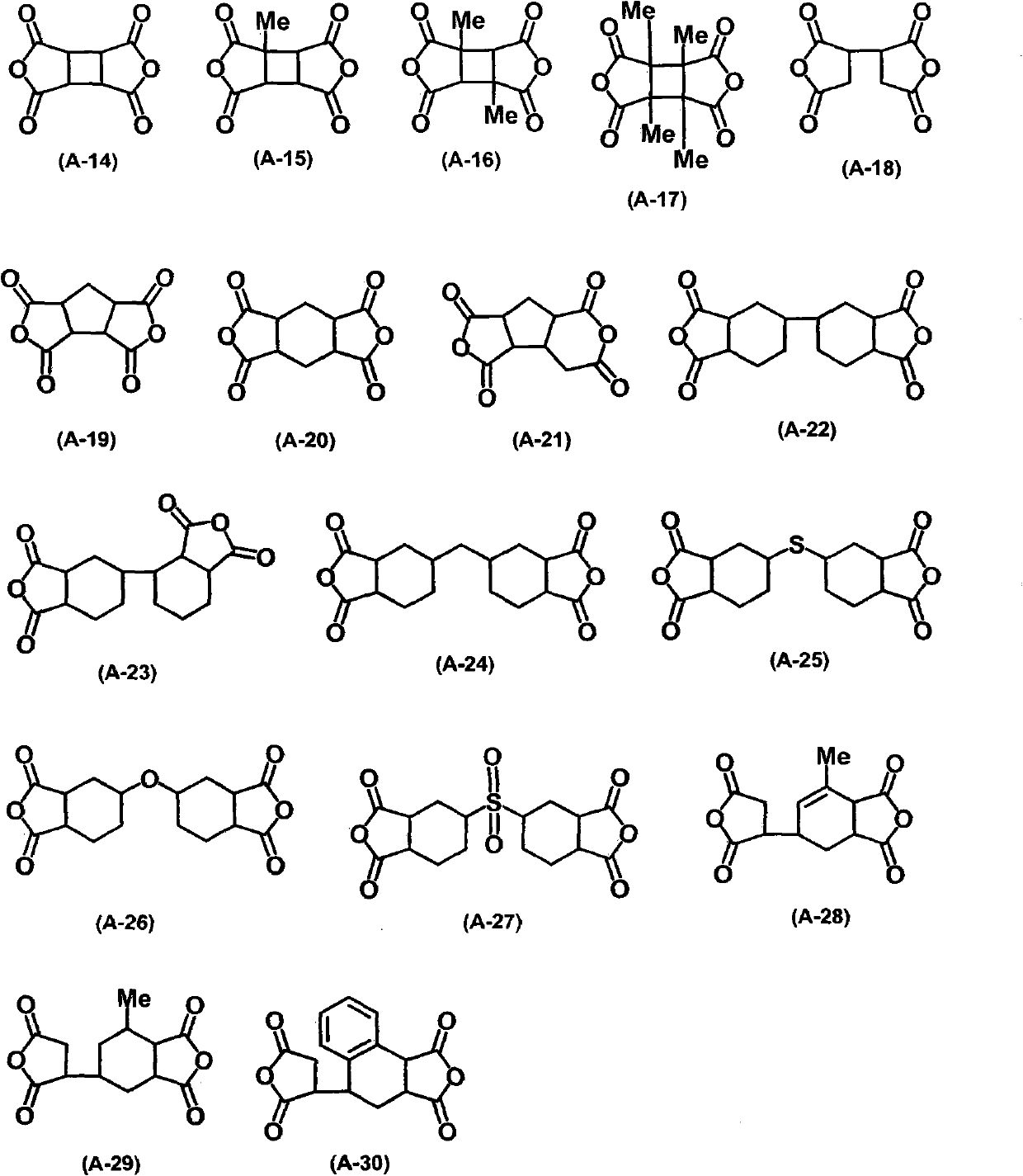

[0185] (Preparation of polyamic acid varnish A>

[0186] DDM (2.2611g, 11.405mmol) was dissolved in NMP (22.5g), the anhydride (I-1) (0.9988g, 2.851mmol), PMDA (0.6219g, 2.851mmol), and CBDA (1.1183g, 5.702mmol) ) Add while keeping below room temperature. After stirring for 2 hours, NMP (10.0 g) and BC (12.5 g) were added. The viscosity of this solution was 83 mPa·s. This solution was stirred at 70°C for about 4 hours to obtain varnish A with a viscosity of 34 mPa·s. The weight average molecular weight of the polyamic acid of this varnish was 52,000.

[0187] [Synthesis example 2~Synthesis example 23]

[0188]

[0189] With the raw material compositions shown in Table 1 and Table 2, the polyamic acid varnishes B to W were prepared by the same method as Synthesis Example 1, and physical properties were measured in the same manner as Synthesis Example 1. In addition, the parentheses indicate mole percentage.

[0190]

[0191]

[0192]

[0193]

example 1

[0195]

[0196] 1.0 g of varnish A was weighed into a sample bottle, and a mixed solvent of NMP / BC=1 / 1 (weight ratio) was added to obtain 1.67 g. Next, a polyamic acid solution with a polymer concentration of about 3% by weight was dropped on the transparent glass substrate, and coating was performed by the spinner method (2,000 rpm, 15 seconds). After coating, the substrate was heated at 80°C for 3 minutes to evaporate the solvent, and then heat treated in an oven at 230°C for 20 minutes. The polyimide film with a film thickness of about 70 nm was subjected to rubbing treatment (extrusion: 0.3 mm, table feed speed: 60 m / s, rotation speed: 1000 rpm, rubbing cloth: YA-18-R (ray of rayon)). Then, the glass substrate formed with the alignment film was ultrasonically cleaned in ultrapure water for 5 minutes, and then dried in an oven at 120°C for 30 minutes.

[0197] The surface on which the alignment film is formed is the inner side, and the rubbing direction becomes anti-parallel,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Delay value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com