Method for compounding nano ceramic silane composite film before spraying aluminum product

A silane composite film, nano-ceramic technology, applied in the direction of metal material coating process, can solve the problems of coating peeling, affecting the adhesion of aluminum materials, etc., and achieve the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

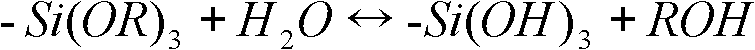

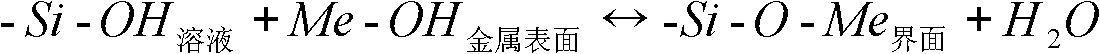

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with embodiment:

[0036] A method for composite nano-ceramic silane composite film before aluminum material spraying comprises the following steps:

[0037] 1. Acid degreasing: immerse the aluminum material in a sulfuric acid tank, in which the free acid content is 130g-200g / L, the temperature is normal temperature, and the time is 1min-3min;

[0038] 2. Water washing: immerse the degreased aluminum material in water, the water should keep overflowing, the pH value is ≥ 2, the temperature is normal temperature, and the time is 1min to 2min;

[0039] 3. Alkali etching: immerse the aluminum material in the lye tank, in which the free alkali content is 40-60g / L, the temperature is normal temperature, the time is 1min-3min, and the amount of alkali etching is at least 1.5g / m 2 above;

[0040] 4. Water washing: immerse the aluminum material after alkali etching in water, the water should keep overflowing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com