Method for preparing porous carbon material by utilizing waste in leather making with aldehyde-plant combined tanning method

A porous carbon material combined with tanning technology, which is applied in the field of preparation of porous carbon materials, can solve problems such as solid waste generation, achieve the effects of reducing the application ratio, improving resource allocation, and solving the problem of chromium pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

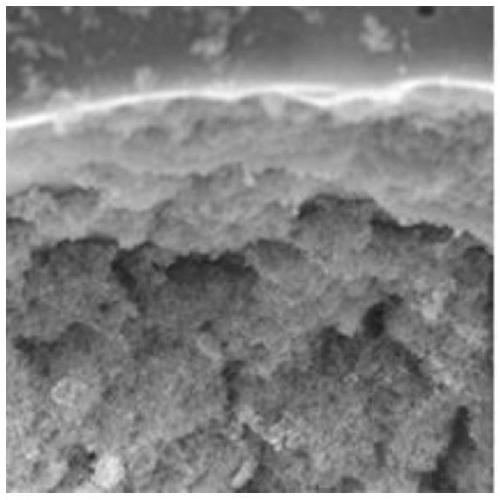

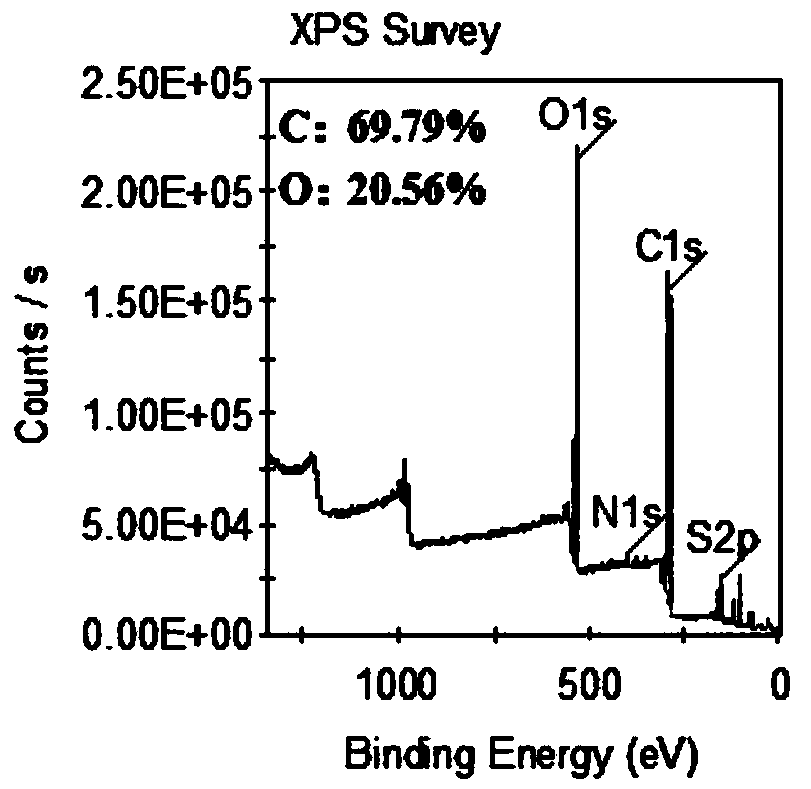

[0061] Example 1, a method for preparing porous carbon materials from wastes in the aldehyde-vegetable combined tanning process,

[0062] Including the following steps,

[0063] Firstly, use alkaline protease preparation to pretreat the waste produced in the process of aldehyde-vegetable combined tanning. The pretreatment steps are as follows:

[0064] (1) Enzyme treatment step: carry out in the drum, after the aldehyde-plant waste is collected and weighed dry weight (about 1 kg), the water consumption is 150% of the dry weight; rotate for 15 minutes to completely soak the water; then add alkali Sodium salt or calcium salt, make the pH of the solution reach 10, add 1% alkaline protease, the activity is 5000 U-10000 U, after reacting for 1 hour, the temperature is 40 ℃ - 60 ℃, wash, dry and pulverize;

[0065] Above-mentioned basic sodium salt can adopt sodium chloride or sodium sulfate or sodium carbonate or sodium hydroxide or sodium bicarbonate or sodium acetate.

[0066] ...

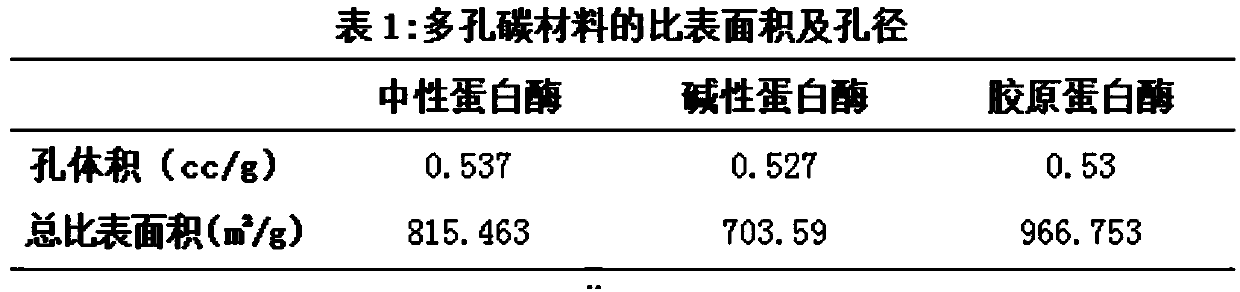

Embodiment 2

[0072] Example 2, a method for preparing porous carbon materials using wastes in aldehyde-vegetable combined tanning process,

[0073] Including the following steps,

[0074] Firstly, neutral protease preparation is used to pretreat the waste generated in the aldehyde-vegetable tanning process, and the pretreatment steps are as follows:

[0075] (1) Enzyme treatment: carry out in the drum, after the aldehyde-plant waste is collected and weighed dry weight (about 1 kg), the water consumption is 150% of the dry weight; rotate for 15 minutes to completely soak the water; then add a small amount Sodium bicarbonate, make the pH of the solution reach 7, add 8% neutral protease, activity (5000 U-10000 U), temperature at 40°C-60°C, react for 1.5 h, wash, dry and pulverize;

[0076] (2) Preliminary carbonization step: the pulverized product was reacted at 350 °C for 1.5 h under nitrogen atmosphere, and then heated at 600 °C for 2 h;

[0077] (3) Advanced treatment step: Grind and pul...

Embodiment 3

[0082] Embodiment 3, a kind of method that utilizes the waste in the aldehyde-vegetable combined tanning method to prepare porous carbon material, comprises the following steps:

[0083] (1) Enzyme treatment: carry out in the drum, after the aldehyde-plant waste is collected and weighed dry weight (about 1 kg), the water consumption is 150% of the dry weight; rotate for 15 minutes to completely soak the water; then add a small amount Sodium bicarbonate, make the pH of the solution reach 10, add 0.3% collagenase, activity (50000 U-80000 U), temperature at 40°C-60°C, react for 1.5 h, wash, dry and pulverize;

[0084] (2) Preliminary carbonization step: react the pulverized product at 350 °C for 1.5 h in a nitrogen atmosphere, then raise the temperature to 600 °C for 2 h;

[0085] (3) Advanced treatment step: Grind and pulverize the product after preliminary carbonization, mix it with potassium salt at a mass ratio of 1:2, soak it in water, keep stirring and reacting at 45°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com