System for measuring temperature in thyristor in real time

A technology of real-time measurement and thyristor, applied in thermometers, measuring devices, measuring heat, etc., can solve problems such as blank measurement methods, and achieve the effects of fast demodulation speed, high reliability, and good linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The measuring system of the present invention will be further described in detail below in conjunction with the accompanying drawings.

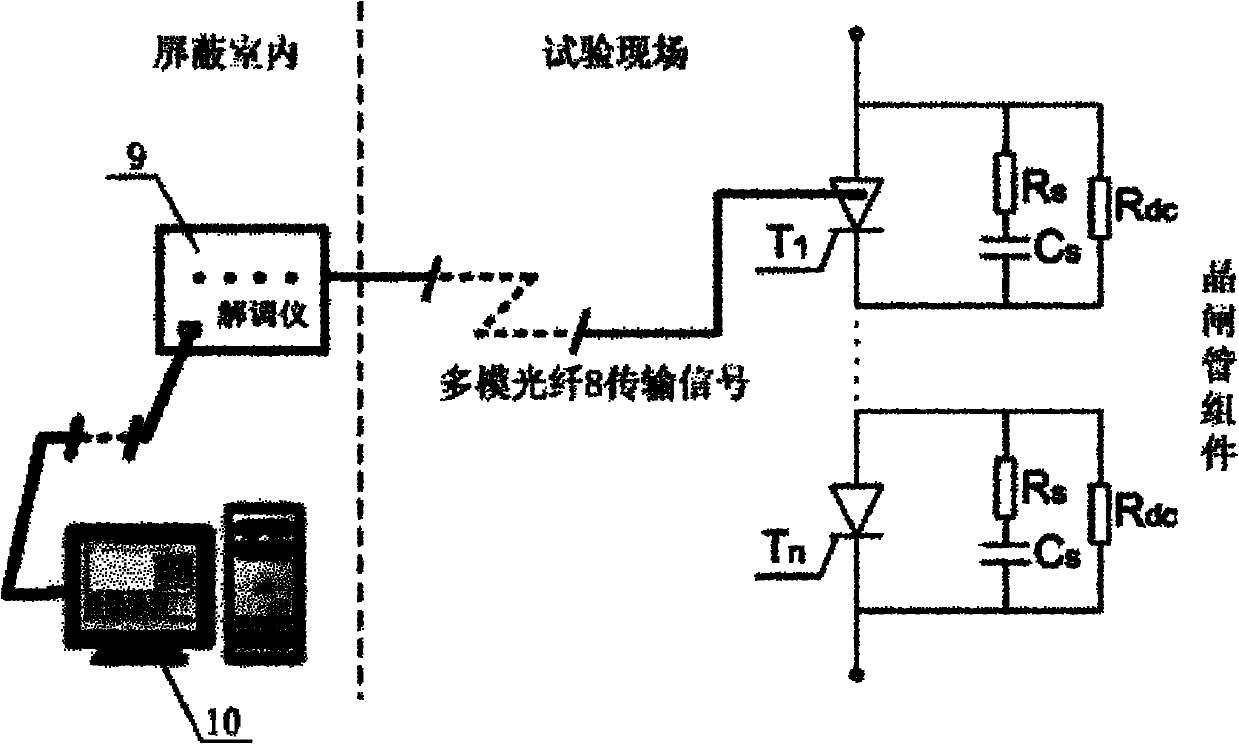

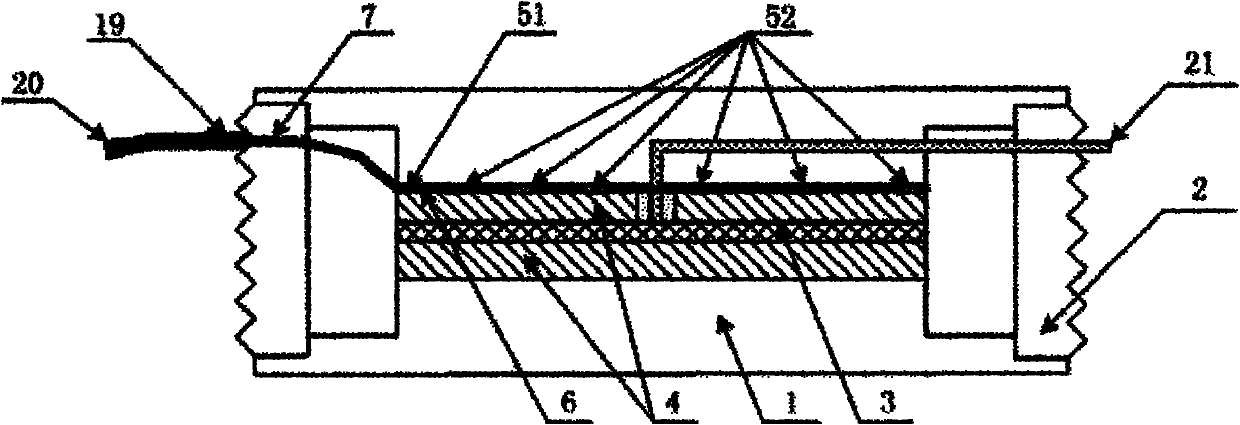

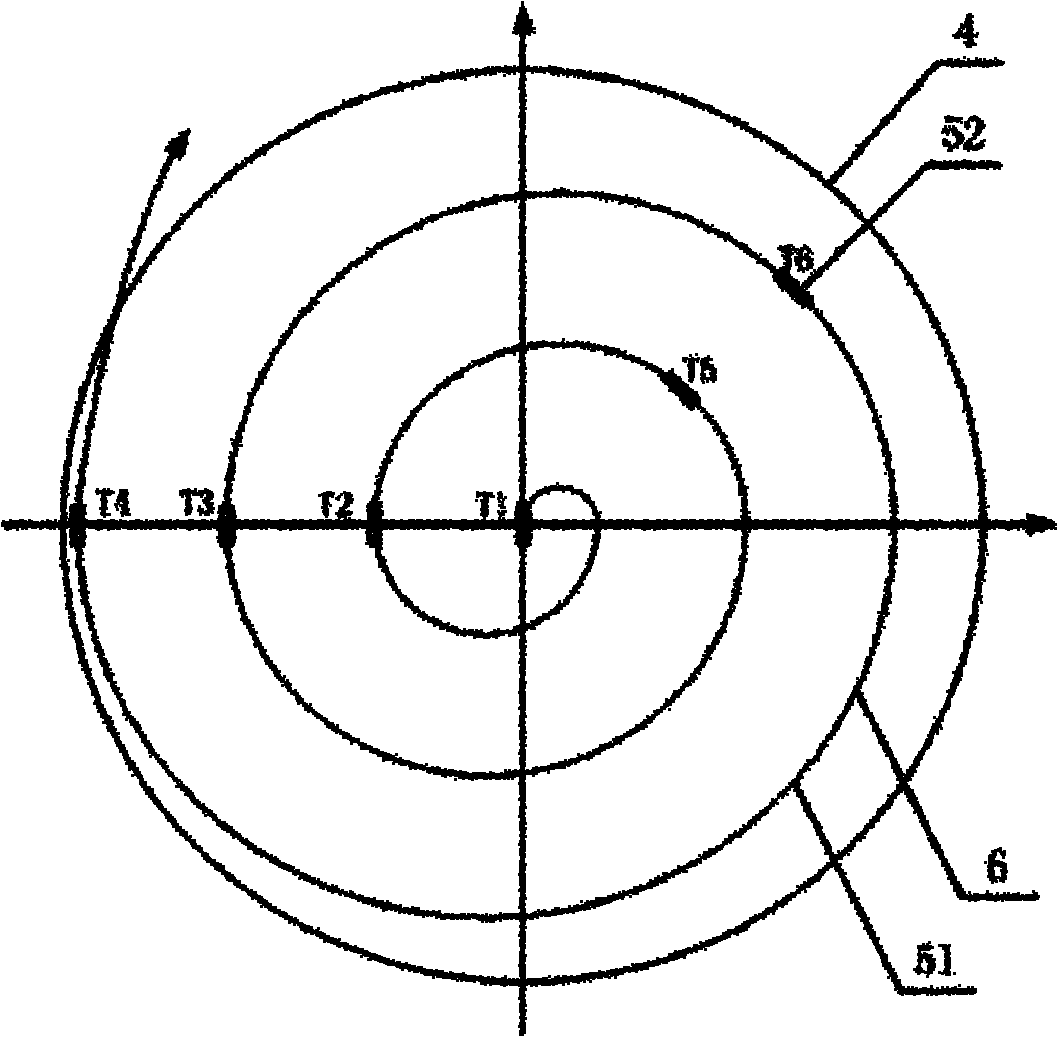

[0024] The thyristor converter valve is the core component of the system operation. The junction temperature of the thyristor changes with the external working conditions. The series voltage equalization mechanism of the converter valve, internal and external overvoltage, overcurrent, thyristor reverse recovery process, trigger control system, protection system, etc. All aspects of characteristics play a decisive role. Such as figure 1 As shown, the measurement system of the present invention is mainly composed of a fiber grating temperature sensor 5 located in the thyristor, a demodulator 9 and a background computer 10. In the figure, the capacitor and resistor connected to the thyristor form a thyristor assembly together with the thyristor. The fiber Bragg grating temperature sensor 5 is connected to the demodulator 9 through the mu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com