Conductive probe liquid holdup gauge

A conductivity probe and liquid holdup technology, applied in the direction of material impedance, etc., can solve problems such as difficult to balance stable output and fast response speed, poor anti-interference ability of signal source and line, poor anti-interference signal processing circuit, etc. Achieve good stability and dynamic response speed, simplify the signal source and signal processing circuit, and suppress the effect of capacitive reactance components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

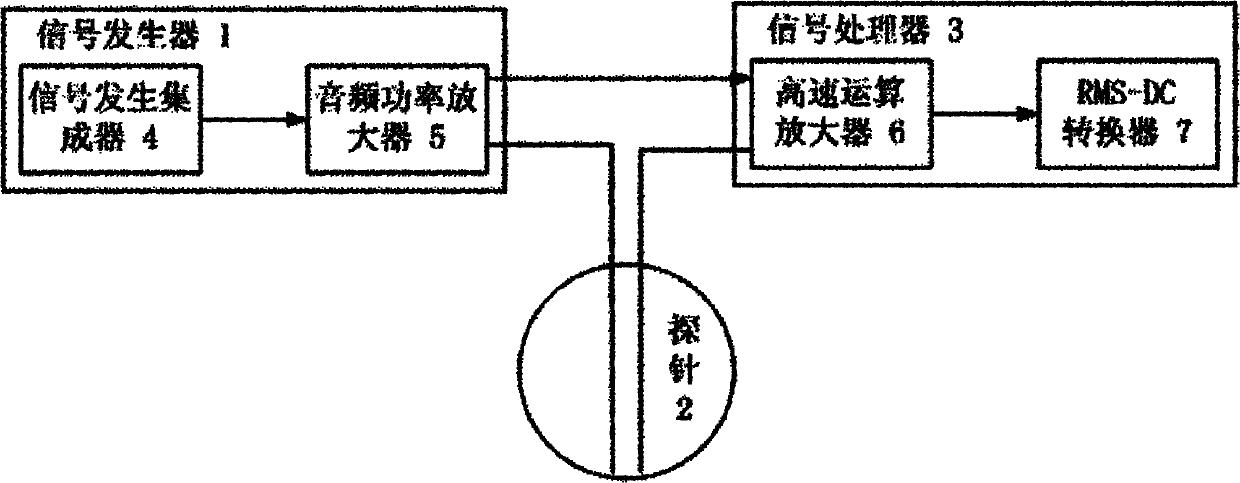

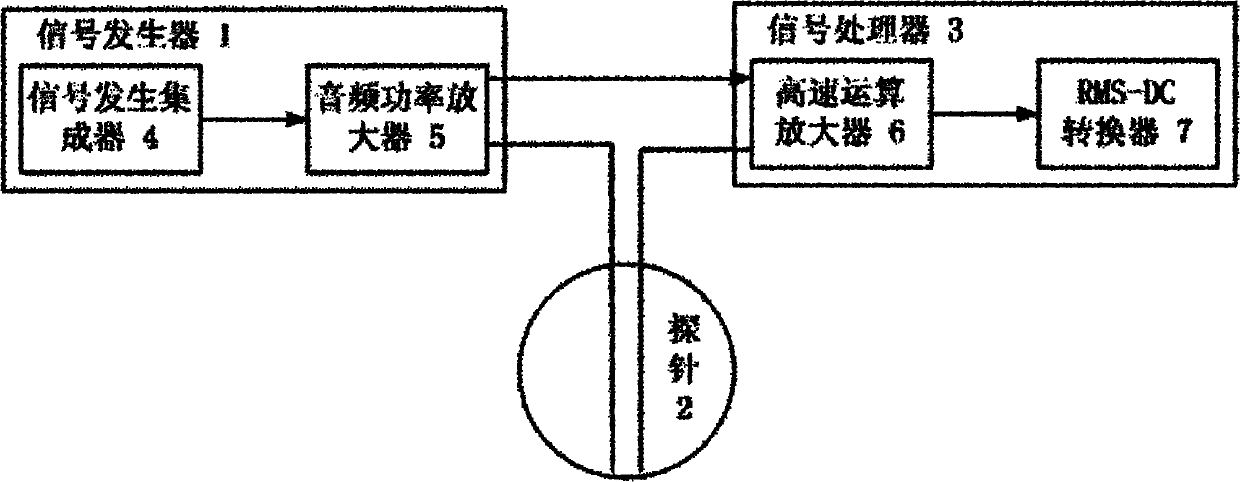

[0011] Such as figure 1 As shown, the present invention includes a signal generator 1, a probe 2 and a signal processor 3, wherein, the signal generator 1 contains a signal generation integrator 4 and an audio power amplifier 5; the signal processor 3 contains There is a high-speed operational amplifier 6 and an RMS-DC (AC voltage to DC effective value) converter 7 .

[0012] The signal generating integrated circuit 4 in the signal generator 1 outputs a high-frequency sine wave signal, which is amplified by the audio power amplifier 5 and used as the output signal source of the signal generator 1 to provide a high-frequency signal for the probe 2 Signal. In this way, the sine wave signal amplified by the audio power amplifier 5 can not only increase the load capacity of the signal generator 1 , but also increase the output frequency of the signal ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com