Power conversion device and induction heating device

A technology of power conversion device and induction heating device, which is applied in the direction of induction heating device, induction heating, electric heating device, etc., can solve the problems of reducing pulsating current, frequency and phase will not be correctly consistent, etc., to suppress heat generation and prolong life , to achieve the effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0064] figure 1 It is a figure which shows the structure of the motor drive apparatus 1 which is one Example of the power conversion apparatus of this invention.

[0065] Such as figure 1 As shown, the motor drive device 1 is composed of an inverter circuit 4 , a capacitor 5 , a current sensor 6 , an inverter circuit 7 , and a control unit 8 . The inverter circuit 4 of the motor drive device 1 is connected to the DC power supply 2 , and the inverter circuit 7 is connected to the motor 3 .

[0066] The converter circuit 4 is configured including an inductor, a switch, and the like. The converter circuit 4 switches on / off the switch according to the pulse width modulation (Pulse Width Modulation, hereinafter abbreviated as "PWM") control performed by the control unit 8, thereby boosting the DC voltage supplied from the DC power supply 2 to desired DC voltage. IGBT, MOSFET, etc. are used for the switch.

[0067]The inverter circuit 7 is a three-phase inverter for driving the...

Embodiment approach 2

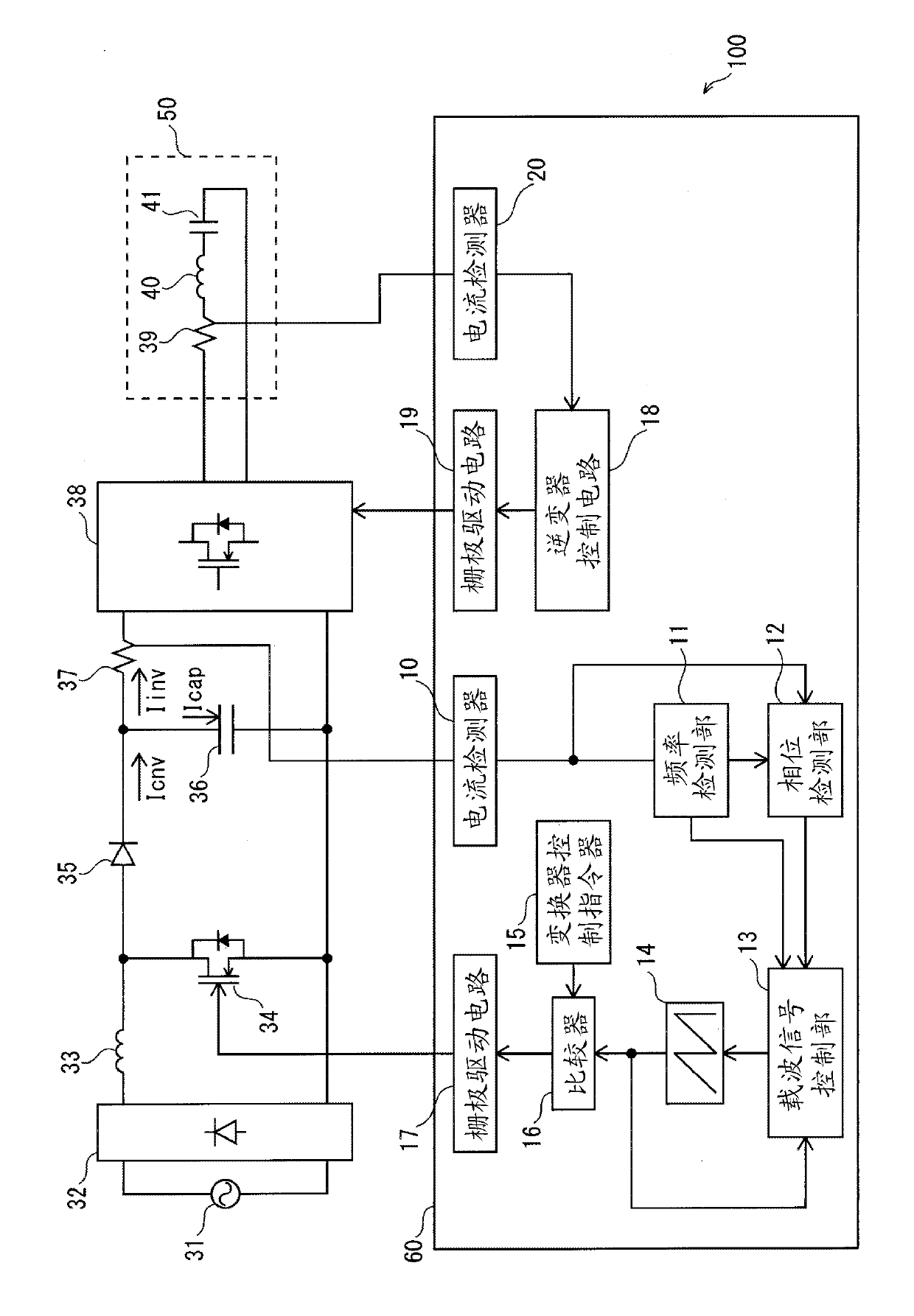

[0097] image 3 It is a figure which shows the structure of the induction heating apparatus 100 which is one Example of the induction heating apparatus of this invention.

[0098] Such as image 3 As shown, the induction heating device 100 is composed of a converter circuit, a capacitor 36, a current sensor 37, an inverter circuit 38, a heater 50 and a control unit 60, and the converter circuit is composed of a diode bridge 32, a coil 33, a switch 34 and a diode 35. As a configuration, the heater 50 is constituted by a current sensor 39 , a heating coil 40 , and a resonant capacitor 41 as a load circuit.

[0099] The induction heating device 100 is a heating conditioner. Specifically, it has a top plate (not shown) on the upper part of the heater 50. By supplying a high-frequency current from the inverter circuit 38 to the heating coil 40, the load pot placed on the top plate is for heating.

[0100] The inverter circuit is connected to the AC power supply 31 , and converts...

Embodiment approach 3

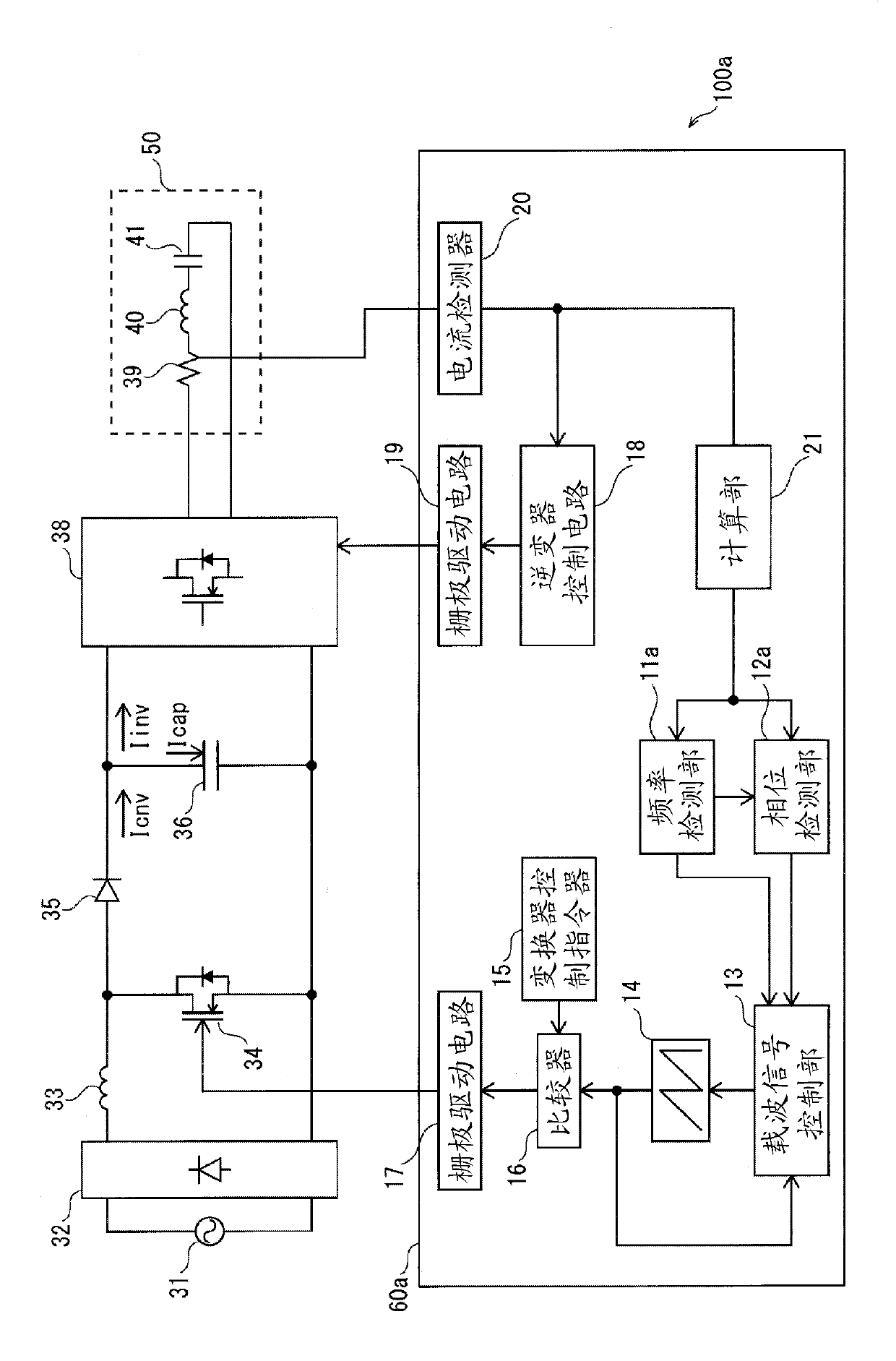

[0115] In Embodiment 2 above, an example was shown in which the current sensor 37 is inserted between the capacitor 36 and the inverter circuit 38 to directly detect the current Iinv flowing from the capacitor 36 to the inverter circuit 38 . Here, as Embodiment 3, an example in which a current sensor between the capacitor 36 and the inverter circuit 38 is not required by using the detection result of the load-side current sensor 39 will be described.

[0116] Figure 4 It is a figure which shows the structure of the induction heating apparatus 100a which concerns on one Embodiment of this invention.

[0117] Such as Figure 4 As shown, the induction heating device 100a is composed of a converter circuit, a capacitor 36, an inverter circuit 38, a heater 50 and a control unit 60a. The converter circuit is composed of a diode bridge 32, a coil 33, a switch 34 and a diode 35. The heater 50 is composed of a current sensor 39 , a heating coil 40 and a resonant capacitor 41 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com