Side chain type sulfonated polyphenyl ether and preparation method thereof

A technology of sulfonated polyphenylene ether and polyphenylene ether, which is applied in the field of side-chain sulfonated polyphenylene ether, can solve the problems of long synthesis route and high temperature polymerization, and achieve the effects of good mechanical properties, high electrical conductivity and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

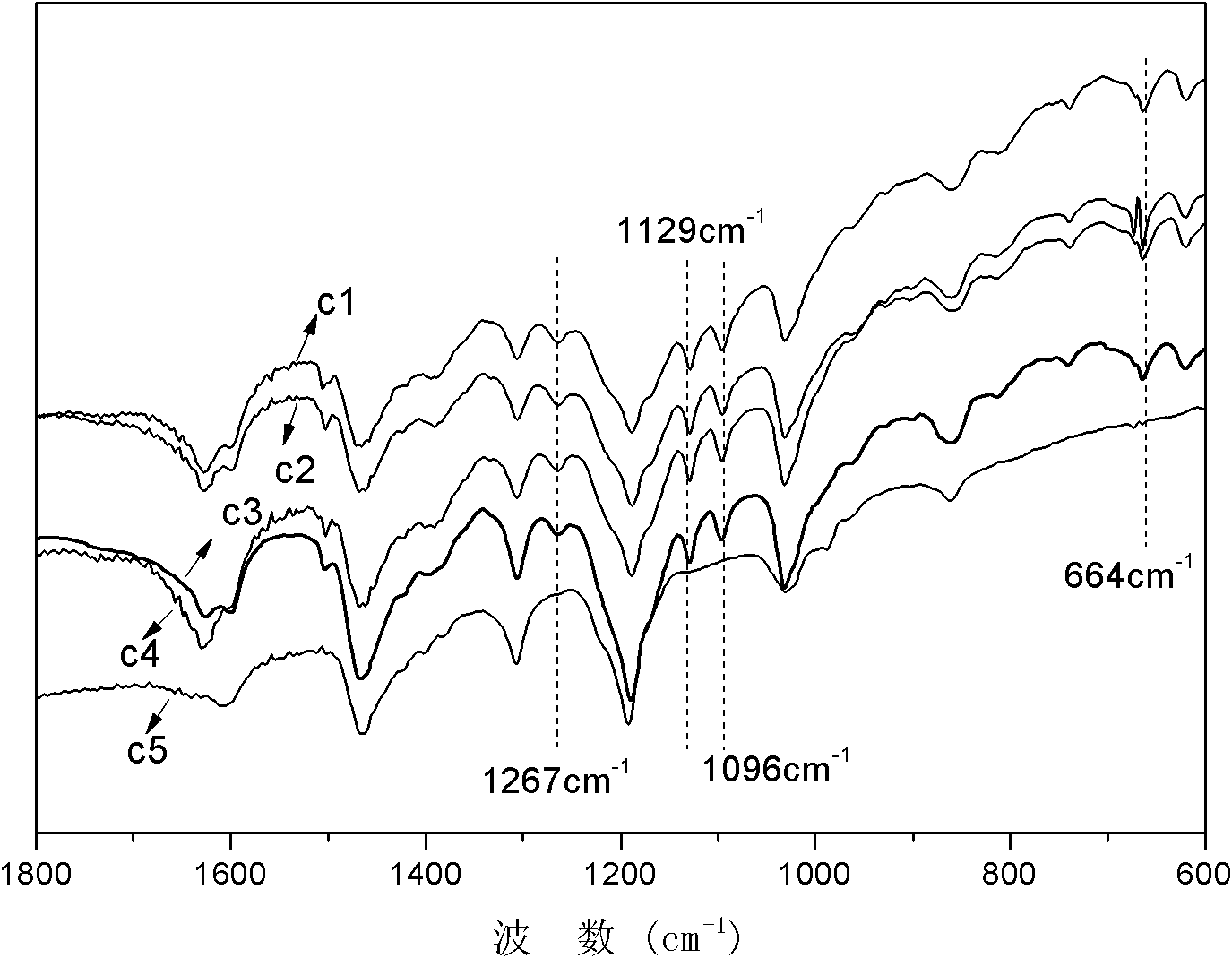

[0025] Example 1: Synthesis of side-chain sulfonated polyphenylene ether with theoretical side-chain sulfonic acid substitution degree of 40%

[0026] Bromomethylated polyphenylene ether with a bromomethyl content of 10 mmol, 4 mmol of 2-naphthol-6-sodium sulfonate, 5.2 mmol of anhydrous potassium carbonate, and 120 mL of 1-methyl-2-pyrrolidone (NMP ) into a 250mL three-necked round-bottomed flask, ventilated with nitrogen, stirred and reacted at 65°C for 24 hours, then poured the reaction solution into water, and the resulting precipitate was filtered, washed, and dried to obtain the product of the present invention.

Embodiment 2

[0027] Example 2: Synthesis of side-chain sulfonated polyphenylene ether with theoretical side-chain sulfonic acid substitution degree of 65%

[0028] Add bromomethylated polyphenylene ether with a bromomethyl content of 10 mmol, 6.5 mmol of sodium 2-naphthol-6-sulfonate, 6.7 mmol of anhydrous potassium carbonate, and 120 mL of NMP into a 250 mL three-necked round-bottomed flask in sequence , Nitrogen, stirring and reacting at 65°C for 24 hours, then pouring the reaction solution into water, and filtering, washing and drying the resulting precipitate to obtain the product of the present invention.

Embodiment 3

[0029] Example 3: Synthesis of side-chain sulfonated polyphenylene ether with theoretical side-chain sulfonic acid substitution degree of 80%

[0030] Add bromomethylated polyphenylene ether with a bromomethyl content of 10 mmol, 8 mmol of sodium 2-naphthol-6-sulfonate, 10.4 mmol of anhydrous potassium carbonate, and 120 mL of NMP into a 250 mL three-necked round-bottomed flask in sequence, Nitrogen is blown, the reaction solution is poured into water after stirring and reacting at 65°C for 24 hours, and the resulting precipitate is filtered, washed and dried to obtain the product of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sub-conductivity | aaaaa | aaaaa |

| Proton conductivity | aaaaa | aaaaa |

| Proton conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com