Low-voltage direct-current controlled continuous flow cell electrofusion chip

A technology of electrofusion and cells, which is applied in the direction of hybrid cell preparation, stress-stimulated microbial growth methods, biochemical equipment and methods, etc., which can solve the problems of low cell fusion efficiency, adverse effects of cell activity and aseptic operation, and complex fusion systems and other issues, to achieve the effect of improved anti-interference, reduced requirements for power signal equipment, and low system cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

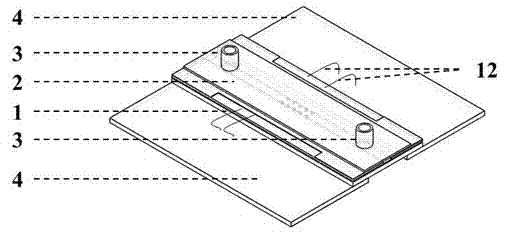

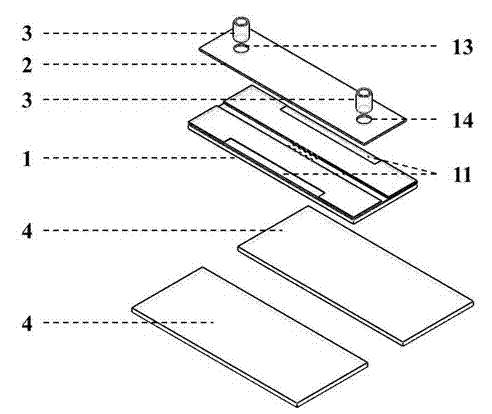

[0038] see figure 1 with figure 2 The continuous flow microelectrode array cell electrofusion chip is composed of a substrate 1 , a cover sheet 2 , a sample inlet and outlet conduit 3 connecting internal and external flow paths, and a metal support sheet 4 .

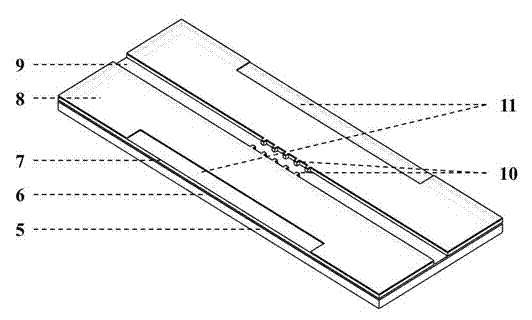

[0039] The structure of the substrate 1 of the chip is shown in image 3 , using silicon material, from bottom to top consists of silicon base layer 5, silicon dioxide insulating layer 6, low-resistance silicon electrode layer 7 and silicon dioxide protective film 8, using micro-processing technology on the low-resistance silicon electrode layer 7 Etching grooves to the silicon dioxide insulating layer 6 forms microchannels 9, the microchannels 9 on both sides are linear, and the microchannels in the middle area are distributed with a series of comb-shaped microelectrodes 10 on both sides of the channel. The micro-electrodes in the shape of a micro-electrode are formed by protruding from the low-resistance silicon ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com