Method for increasing sugar-to-acid conversion rate during fermentation of L-glutamic acid

A technology for fermenting sugar and glutamic acid, which is applied in the direction of fermentation, etc., can solve the problems of unfavorable utilization of glutamic acid sugar solution, slow sugar consumption rate of strains, and reduced conversion rate of sugar and acid, so as to improve the concentration of sugar solution and dissolved oxygen The effect of uneven distribution, overall uniform distribution of sugar solution concentration, and improvement of sugar-acid conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

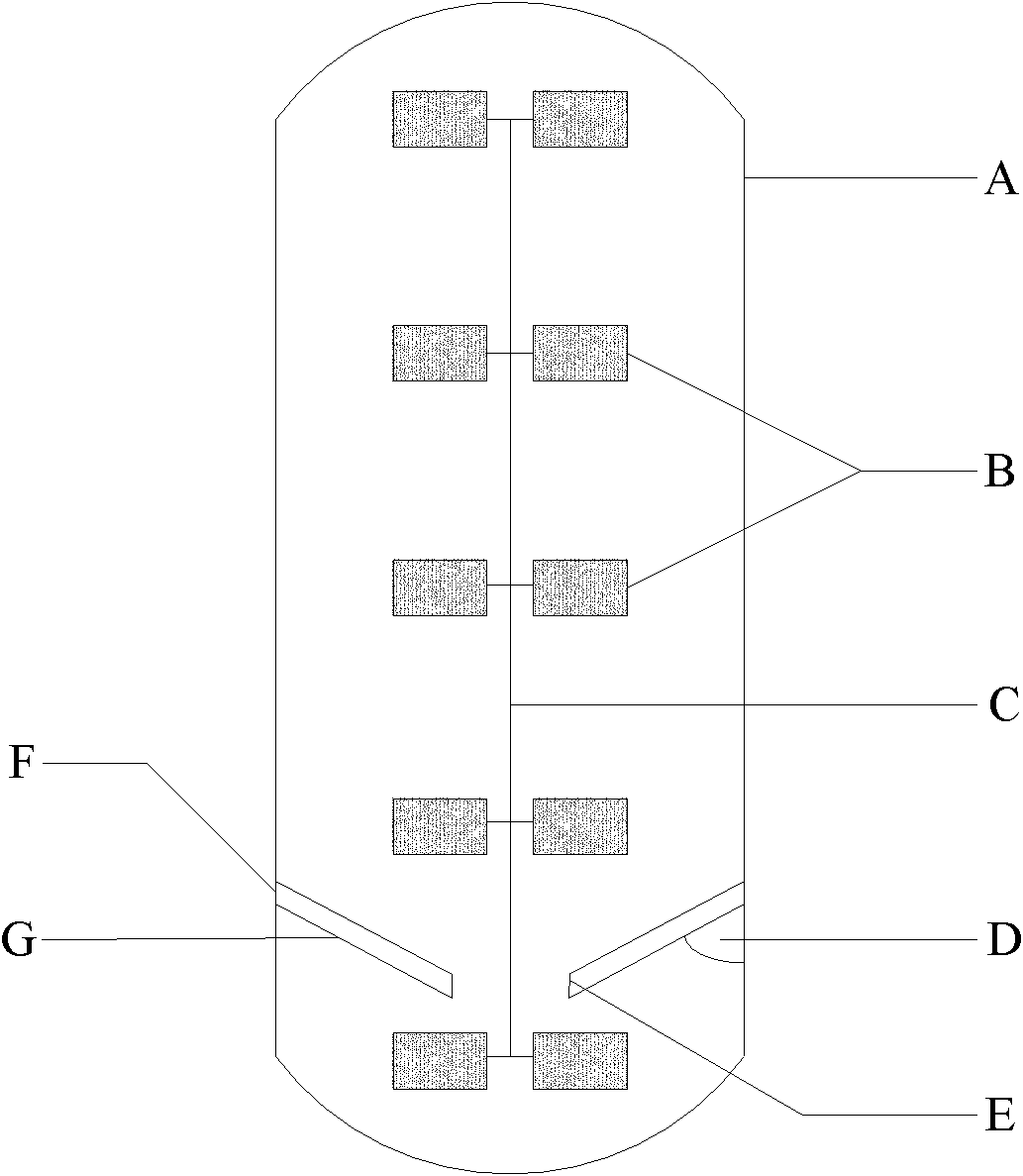

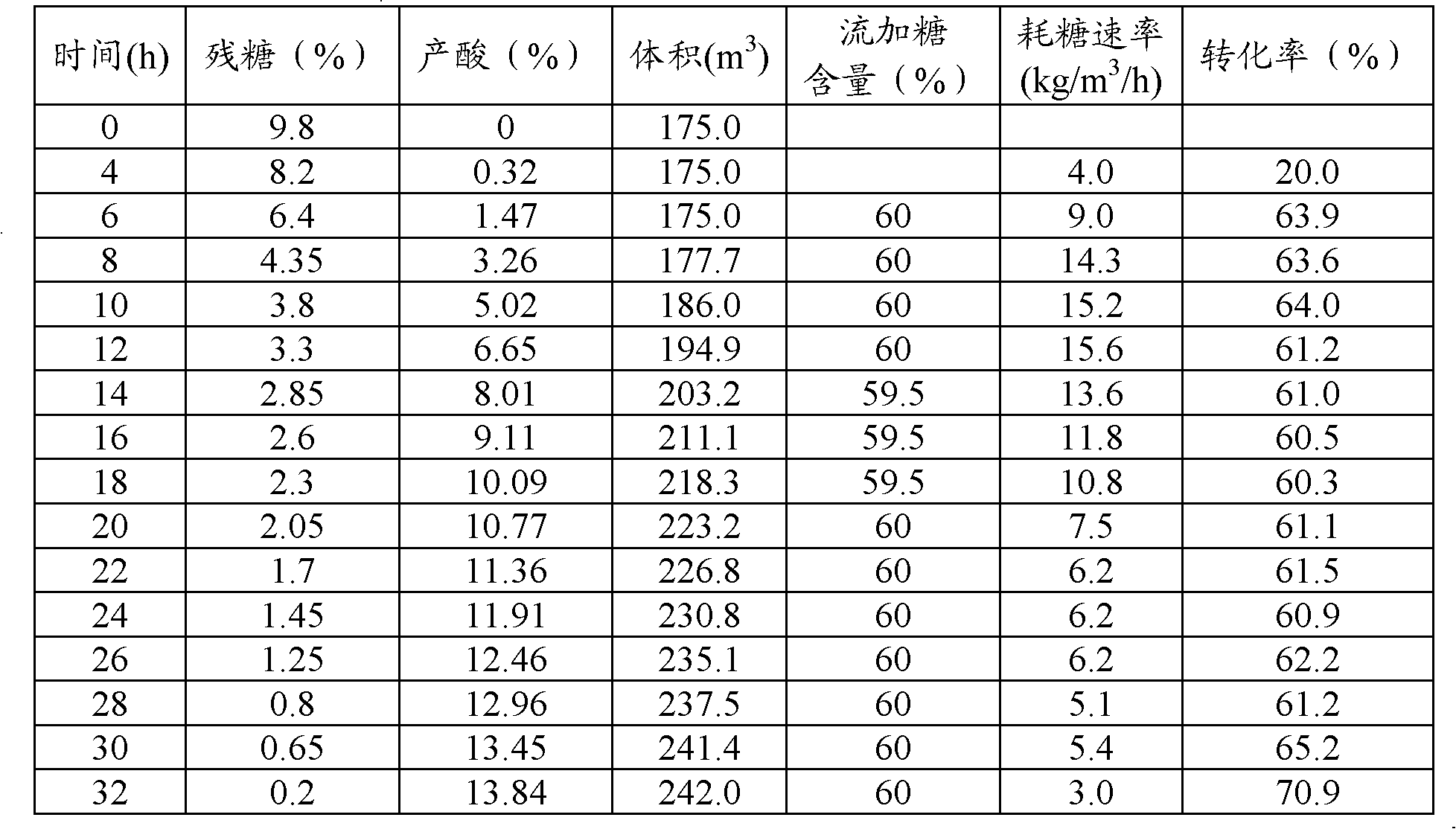

[0022] Embodiment 1: comparative analysis of the method of the present invention

[0023] In this embodiment, the volume is 320m 3 , The height of the side wall is 20000mm, and the horizontal distance from the stirring shaft to the side wall is 4200mm. The fermentation tank is modified, and the two flow-adding sugar pipelines are extended into the fermentation tank. The inner diameter of the pipeline is 90mm, and the vertical angle between the entrance of the pipeline and the inner wall of the fermentation tank The outlet of the pipeline is located above the bottom stirring blade, the vertical distance from the bottom stirring blade is 300mm, and the radial distance from the stirring shaft of the fermenter is 780mm.

[0024] Under the same fermentation conditions, the fermentation tanks before and after the transformation started from the fermentation acid production period (4-32h) at 5m 3 The / h flow rate continued to add sugar for fermentation, and stopped adding sugar unti...

Embodiment 2

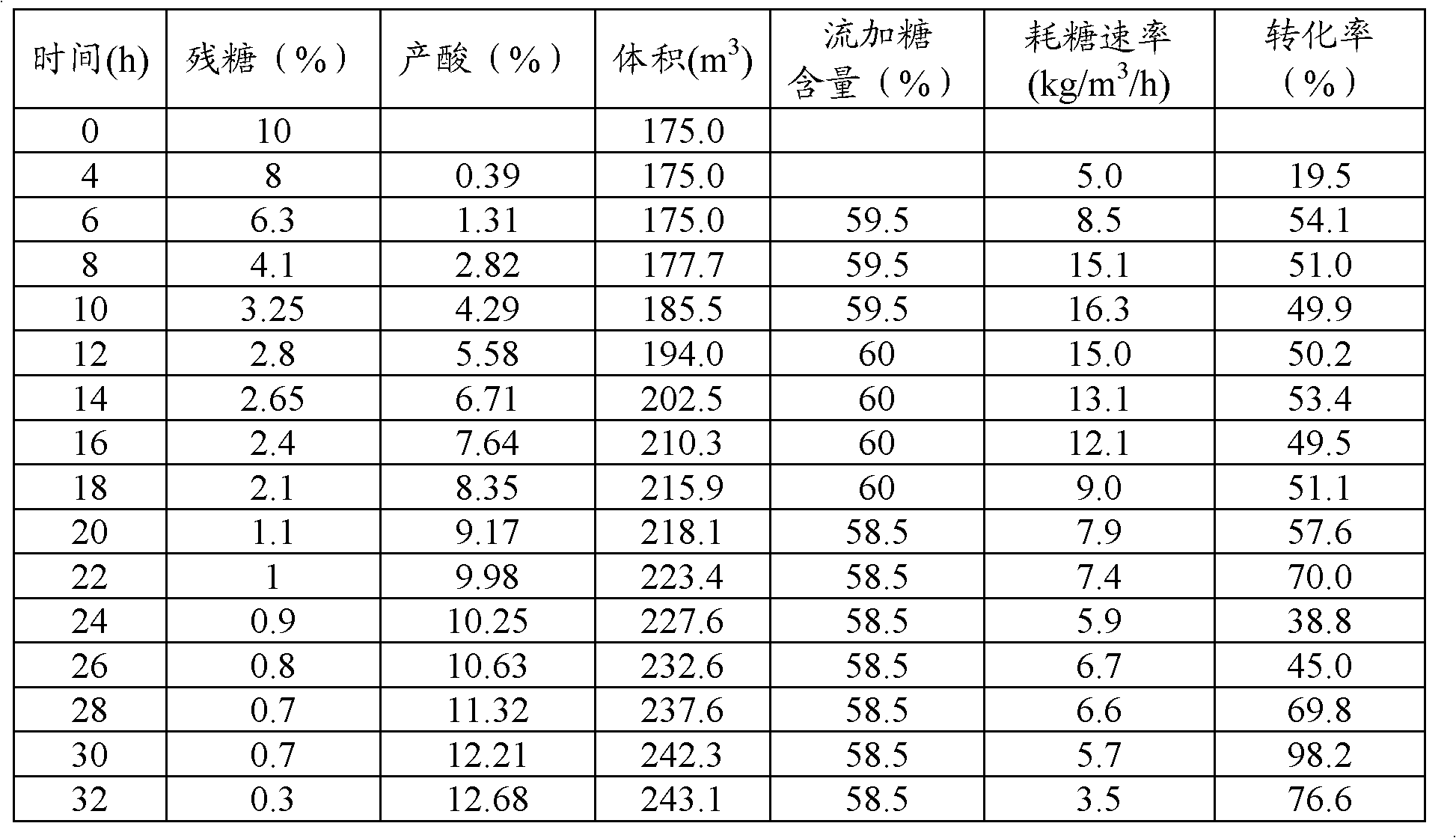

[0032] Embodiment 2: comparative analysis of the method of the present invention

[0033] In this embodiment, the volume is 150m 3 , The height of the side wall is 10000mm, and the horizontal distance from the stirring shaft to the side wall is 2100mm. The fermenter is transformed, and the two flow-add sugar pipelines are extended into the fermenter. The inner diameter of the pipeline is 45mm, and the vertical angle between the entrance of the pipeline and the inner wall of the fermenter The outlet of the pipeline is located above the bottom stirring blade, the vertical distance from the bottom stirring blade is 150mm, and the radial distance from the stirring shaft of the fermenter is 390mm.

[0034] Under the same fermentation conditions, the fermentation tanks before and after the transformation started from the fermentation acid production period (4-32h) at 10m 3 / h continued to add sugar for fermentation, and stopped adding sugar until the fermentation was completed. See...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com