Solid energy storage electric boiler and heat exchanging structure thereof

A heat exchange structure, electric boiler technology, applied in heat storage equipment, steam boilers, indirect heat exchangers, etc., can solve the problems of high heating temperature, large water storage tank, low heat capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

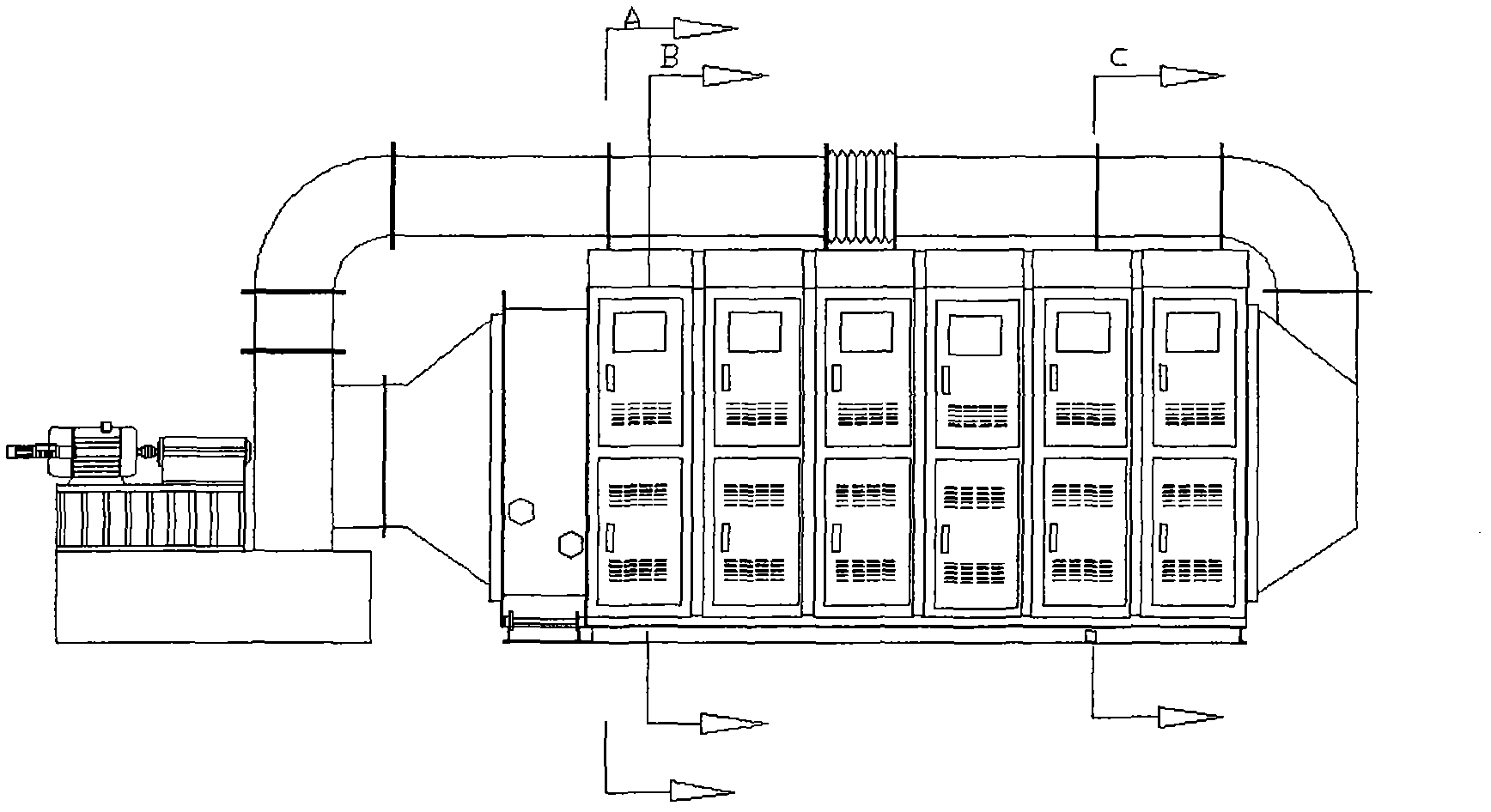

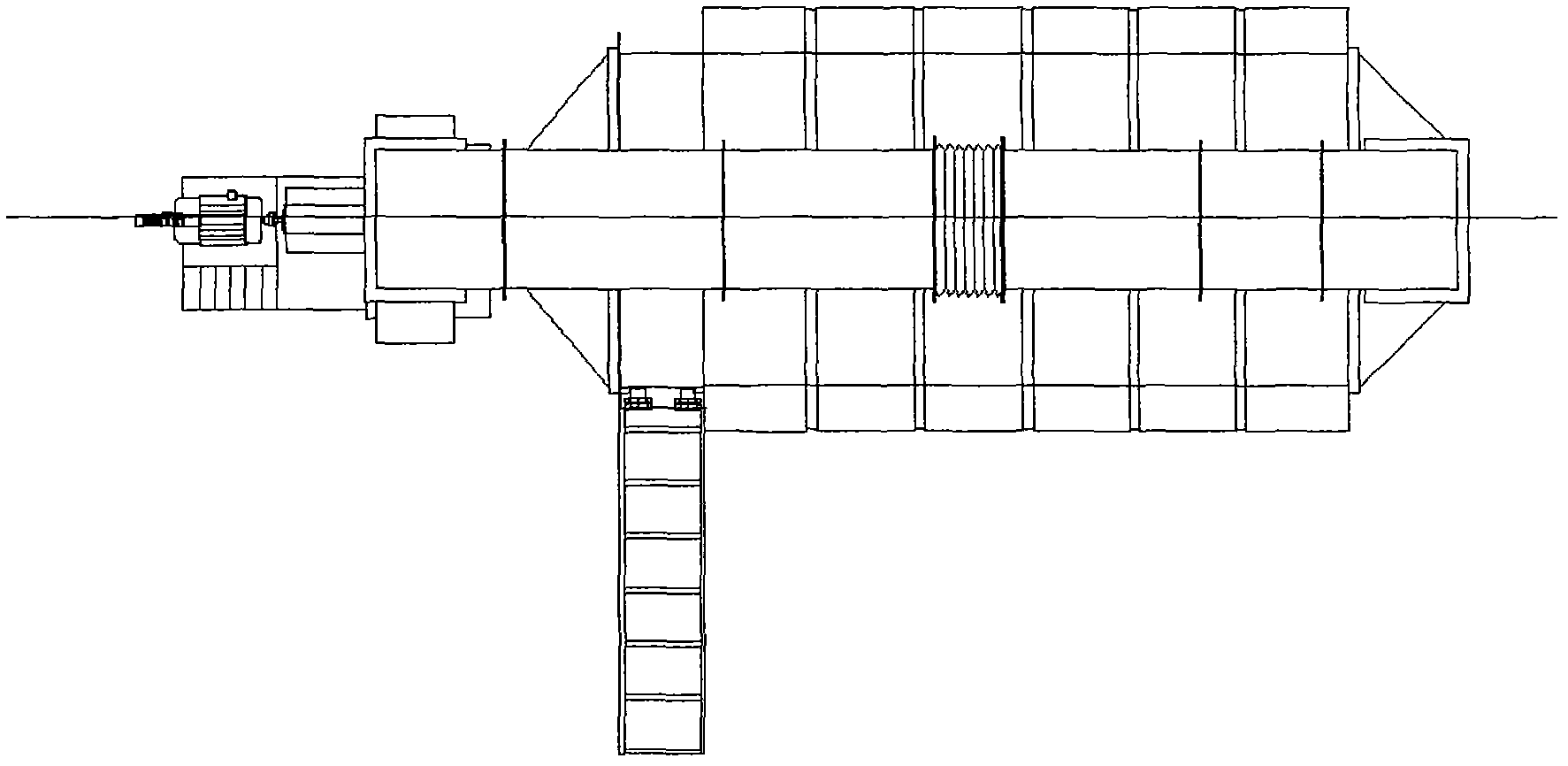

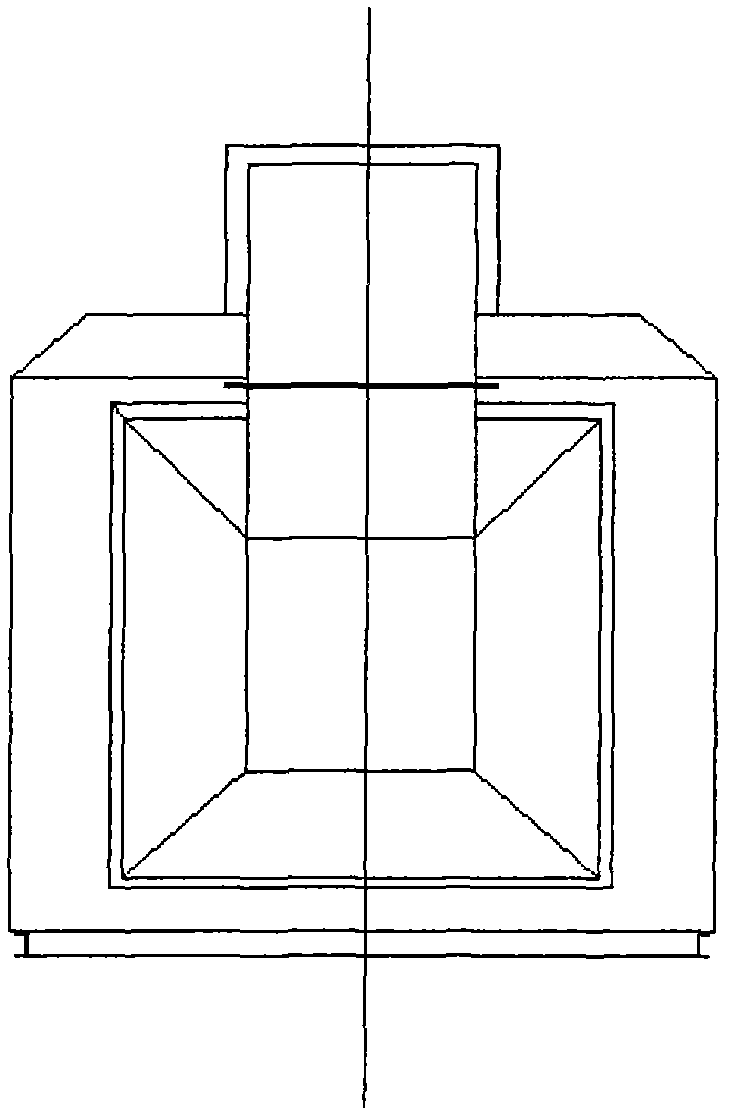

[0041] A certain factory installed a solid energy storage electric boiler provided by the present invention, which uses the heat exchange structure provided by the present invention. Its components include a heat storage structure, a layer of thermal insulation material, a perforated thermal insulation wall 5, a heat exchanger 7, and a shell. The shell includes a metal shell, and the inside is made of thermal insulation bricks 3;

[0042] The two ends of the shell are open with vents, the heat storage structure, the perforated insulation wall 5 and the heat exchanger 7 are arranged in the shell, and the insulation material layer is arranged between the heat storage structure, the perforated insulation wall 5 and the shell. The layer is a combination of 4 or 2 of thermal insulation bricks or thermal insulation mortar;

[0043] The heat storage structure includes a heat pipe 1 that is energized and heated and a heat storage unit made of solid heat storage material. The heat pipe 1 is...

Embodiment 2

[0056] The structure of the solid energy storage electric boiler is the same as that of Example 1, except that the heat storage brick uses magnesium oxide as the main raw material, and the heat storage temperature can also reach room temperature-1000 degrees Celsius.

Embodiment 3

[0058] The structure of the solid energy storage electric boiler is the same as that of Example 1, except that the perforated thermal insulation wall 5, thermal insulation bricks and thermal insulation mortar 4 included in the thermal insulation material layer, and thermal insulation bricks 3 inside the shell are all made of uniform Castable silicate is used instead for construction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com