Preprocessing method for measuring content of noble metal ions in high-purity reagent

A precious metal ion, pretreatment column technology, applied in the preparation of test samples, etc., can solve problems such as measurement result error, and achieve the effect of simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

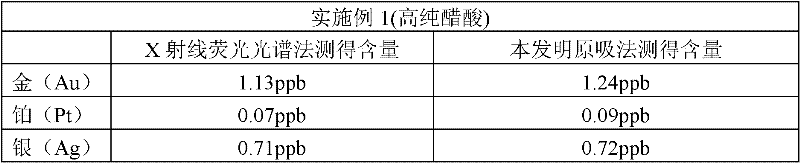

Embodiment 1

[0018] Pass 100g of high-purity acetic acid solution under the condition of 0.05MPa through a pretreatment column with a 0.5μm microporous membrane and immobilized with 5g of polyethylene dithizone laminating resin, remove the microporous membrane, and use 10ml of ethylenediamine hydrogen The sodium oxide solution eluent eluted the precious metal ions enriched on the laminating resin, and the volume was fixed to 25ml with the eluent, and the content of the precious metal ions in the high-purity acetic acid solution was directly sampled. The test results are shown in Table 1.

[0019] Table 1 The original suction method detection result of the present invention is compared with X-ray fluorescence spectrometry detection result

[0020]

Embodiment 2

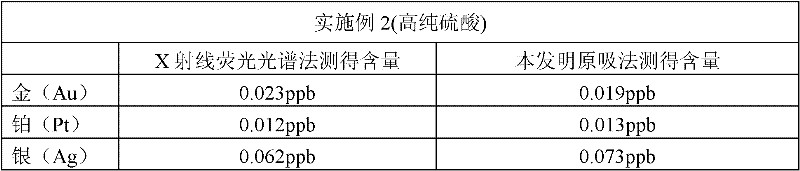

[0022] Pass 100g of high-purity sulfuric acid solution under the condition of 0.01MPa through a pretreatment column with a 2 μm microporous membrane and solidly loaded with 2.5g of polyethylene dithizone complex membrane resin, remove the microporous membrane, and use 8ml of thiourea-hydrochloric acid The solution eluent elutes the precious metal ions enriched on the laminating resin, and the volume is fixed to 25ml with the eluent, and the content of the noble metal ions in the high-purity sulfuric acid solution is directly sampled. The test results are shown in Table 2 below.

[0023] Table 2 The original suction method detection result of the present invention is compared with X-ray fluorescence spectrometry detection result

[0024]

Embodiment 3

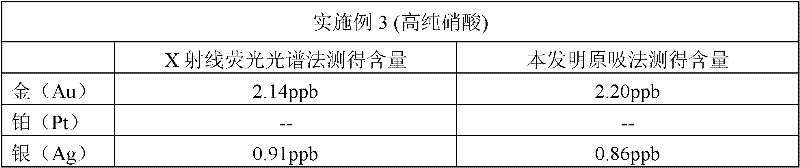

[0026] Pass 100g of high-purity nitric acid solution under the condition of 0.03MPa through a pretreatment column with a 1 μm microporous membrane and solidly loaded with 3.5g of polyethylene dithizone complex membrane resin, remove the microporous membrane, and use 10ml of thiourea-hydrochloric acid The solution eluent elutes the precious metal ions enriched on the laminating resin, and the volume is fixed to 25ml with the eluent, and the content of the noble metal ions in the high-purity nitric acid solution is directly sampled. The test results are shown in Table 3 below.

[0027] Table 3 The original suction method detection result of the present invention is compared with X-ray fluorescence spectrometry detection result

[0028]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com