Transverse micro electro mechanical system (MEMS) microactuator adopting piezoelectric thick film actuating and manufacturing method thereof

A technology of a micro-driver and a manufacturing method, which is applied in the direction of micro-structure technology, micro-structure devices, manufacturing micro-structure devices, etc., can solve the problems of difficult processing, complex structure, low driving performance, etc., and achieve high manufacturing reliability and easy integration , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

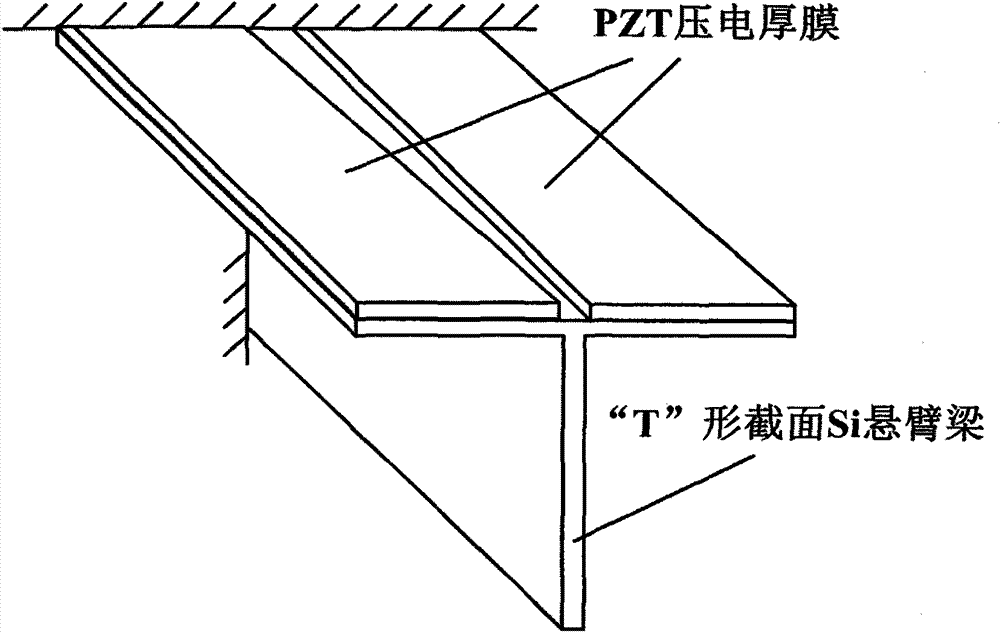

[0028] Such as figure 1 As shown, a transverse MEMS micro-actuator driven by a piezoelectric thick film includes a "T" cross-section cantilever beam formed by a substrate and two PZT piezoelectric thick film driving layers; the two piezoelectric thick film driving layers are located in the " The upper surface of the T”-shaped cross-section cantilever beam is symmetrically distributed, and the thickness of the PZT piezoelectric thick-film driving layer is 2 μm.

[0029] The specific production steps are as follows:

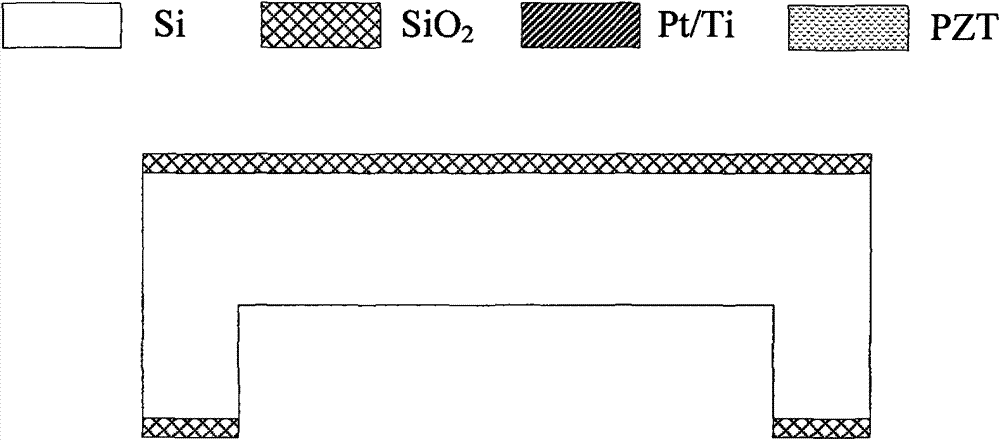

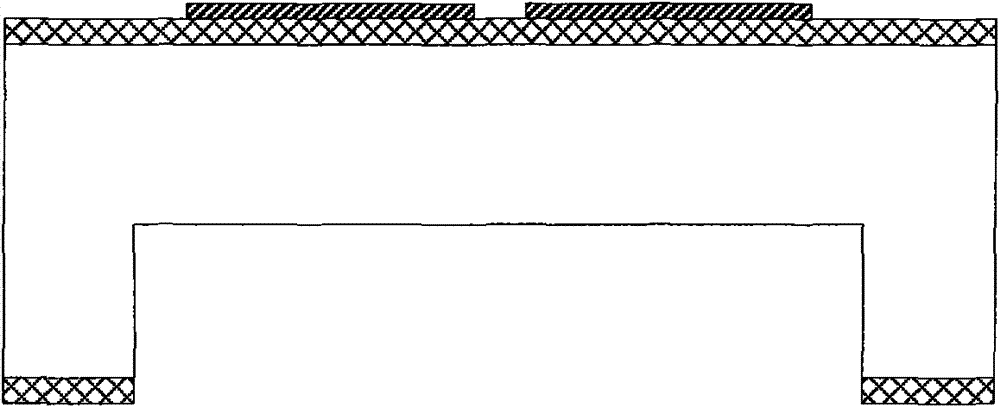

[0030] 1) if figure 2 As shown, first, 2 μm SiO was deposited on both sides of a double-polished (100) Si wafer substrate by a physical enhanced chemical vapor deposition (PECVD) process. 2 barrier layer. After a photolithography process, a photoresist mask pattern is formed on the back of the Si substrate, and SiO is etched by induct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com