Desulfurizing and denitrifying agent for smoke gas

A denitrification agent and flue gas technology, applied in the direction of air quality improvement, dispersion particle separation, chemical instruments and methods, etc., to achieve the effect of less total investment, simple equipment and improved effect

Inactive Publication Date: 2013-02-27

NANJING UNIV OF INFORMATION SCI & TECH

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the desulfurizers used in these technologies are cheap, due to the complexity of the desulfurization process, the desulfurization system equipment is very large and the operation is also very complicated, and there are many limitations in actual use.

For example, it has many shortcomings such as large floor area, large amount of dosing, and high one-time investment.

At the same time, these technologies cannot achieve the purpose of denitrification at the same time, which is undoubtedly unfavorable to the transformation of combustion equipment.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

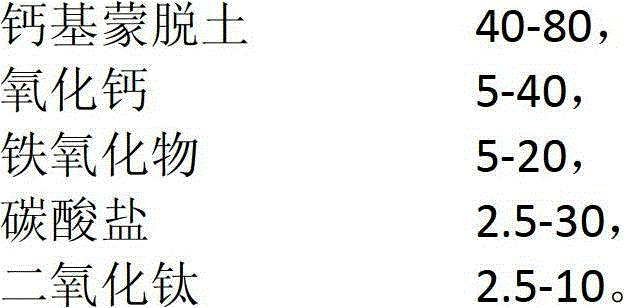

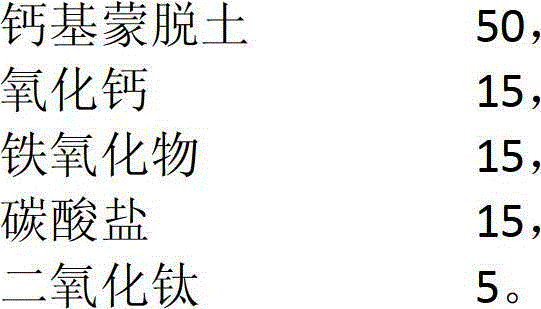

Login to View More Abstract

The invention discloses a smoke gas catalyst capable of simultaneously realizing desulfurization and denitrification, which aims to provide a desulfurizing and denitrifying agent for CTR-ultraviolet radiation smoke gas capable of reducing the investment and operation costs of the device and simultaneously efficiently removing the NO, NO2 and SO2 in the smoke gas. The moke gas desulfurizing and denitrifying catalyst provided by the invention may comprise the following components according to fractional ratio: 40-100% of calcium-based imvite, 0-40% of calcium oxide, 0-20% of iron oxide, 0-30% of carbonate and 0-10% of titanium dioxide, wherein the iron oxide is one or more types of ferrous oxide, iron sesquioxide and ferroferric oxide, and the carbonate is one or more types of calcium carbonate and magnesium carbonate. The desulfurizing and denitrifying agent for CTR-ultraviolet radiation smoke gas is not only suitable for the flue gas desulfurization of a new boiler but also particularly suitable for the improvement in order to construct a combustion device.

Description

technology field; [0001] The invention relates to a desulfurization and denitrification agent, in particular to designing a flue gas desulfurization and denitrification agent Background technique: [0002] The desulfurizers traditionally used in coal-fired power plants are mainly limestone and calcium hydroxide. For example, Finland's LIFAC flue gas desulfurization technology, American ABB's wet flue gas desulfurization technology and semi-dry flue gas desulfurization technology (NID system), etc. There are also NH 3 As a desulfurizing agent technology, such as the electron beam flue gas desulfurization technology researched in Japan. Although the desulfurizers used in these technologies are cheap, due to the complex desulfurization process, the desulfurization system equipment is very large and the operation is also very complicated, and there are many limitations in actual use. For example, it has many shortcomings such as large floor area, large amount of dosing, and...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01D53/83B01D53/60

CPCY02A50/20

Inventor 张泽锋

Owner NANJING UNIV OF INFORMATION SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com