Method for preparing thermoplastic polyurethane (TPU)/ kieselguhr composite material

A thermoplastic polyurethane and composite material technology, applied in the field of thermoplastic polyurethane composite material preparation, can solve problems such as diatomite-modified TPU composite materials that have not yet been seen, and achieve the advantages of short cycle, convenient processing and molding, and improved mechanical properties and heat resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

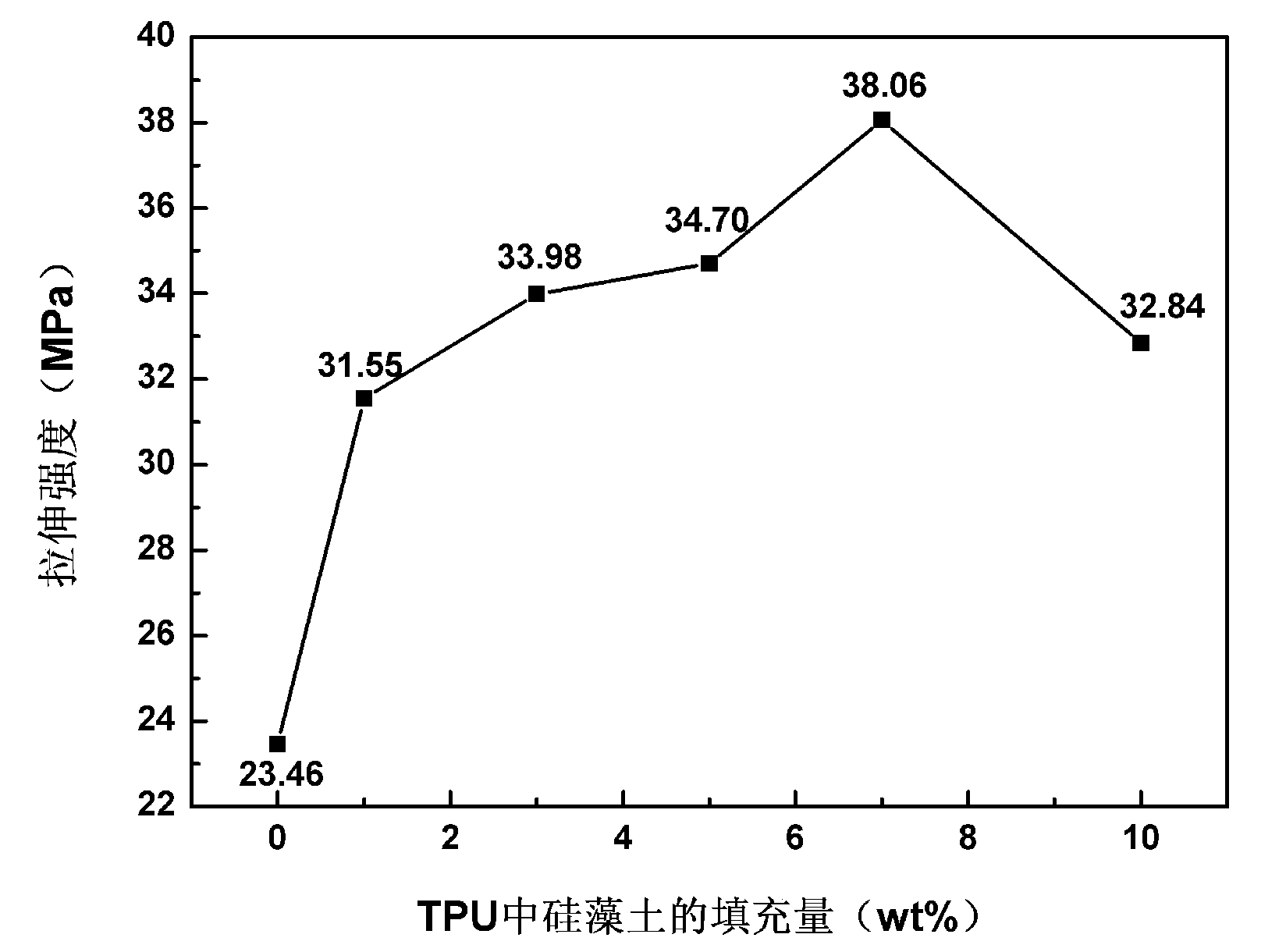

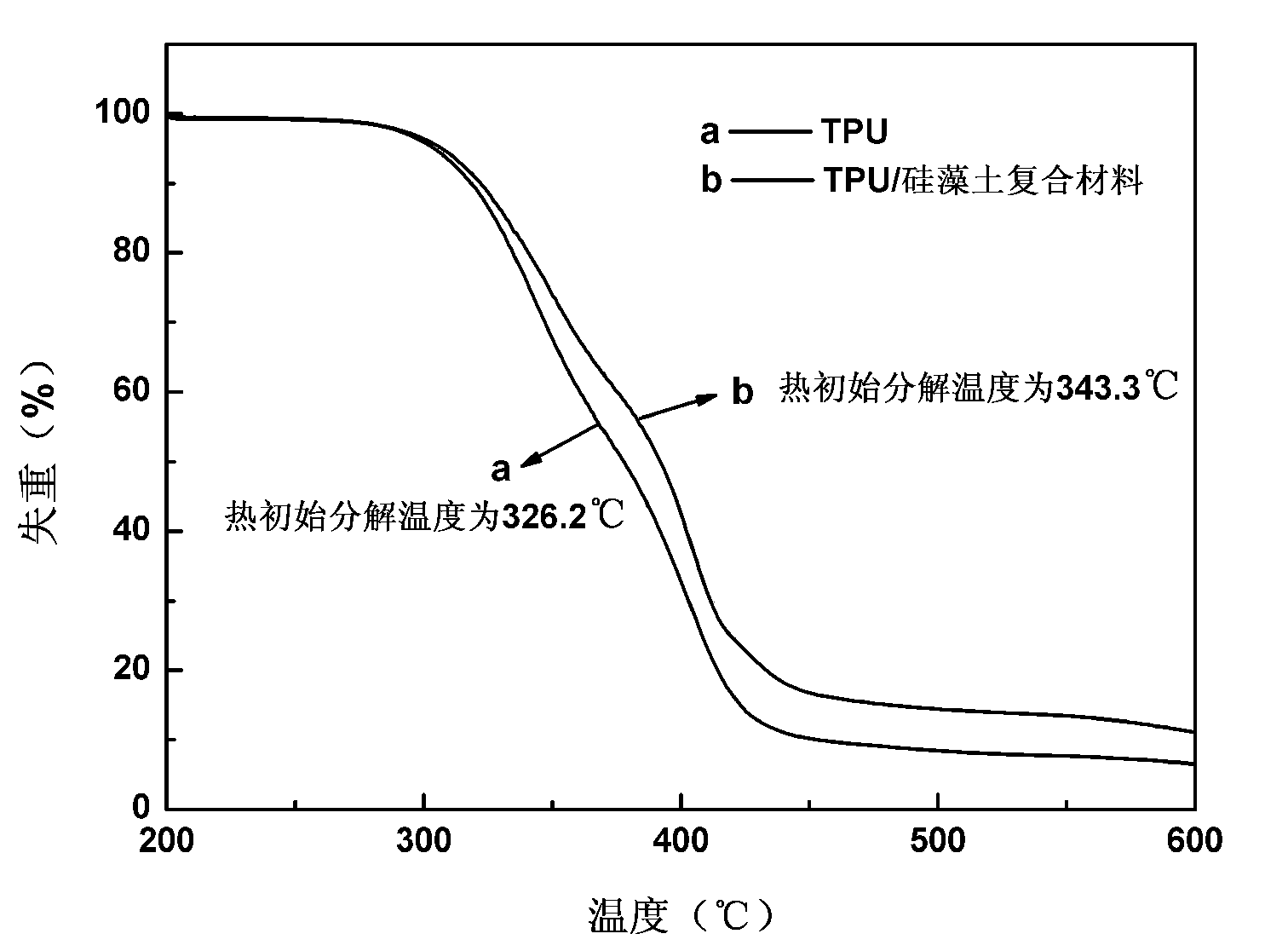

[0029] Weigh 20g of diatomaceous earth with a particle size of 5000 mesh into a three-necked flask, then add 400ml of cyclohexane, 0.4g of n-propylamine and 2g of silane coupling agent KH-570, stir at room temperature for 30min at a stirring speed of 500r / min, and then Stir at 50°C for 30 min. The reacted solution was rotary evaporated at 60° C. for 1 h, and then vacuum dried at 60° C. for 30 h, and diatomaceous earth was collected. Then, weigh 0.1 g of the modified diatomaceous earth into a three-necked flask at room temperature, then add 95 ml of dimethyl sulfoxide, and ultrasonically disperse for 1 hour. Subsequently, 10g of TPU was added to the above solvent, the temperature was raised to 70°C, and the stirring speed was 500r / min for mechanical stirring for 6h. After the TPU is completely dissolved, the mixture is ultrasonically stirred at a stirring speed of 500r / min for 2h, and finally the solvent is evaporated at 80°C to obtain a TPU / diatomite composite material. Field...

Embodiment 2

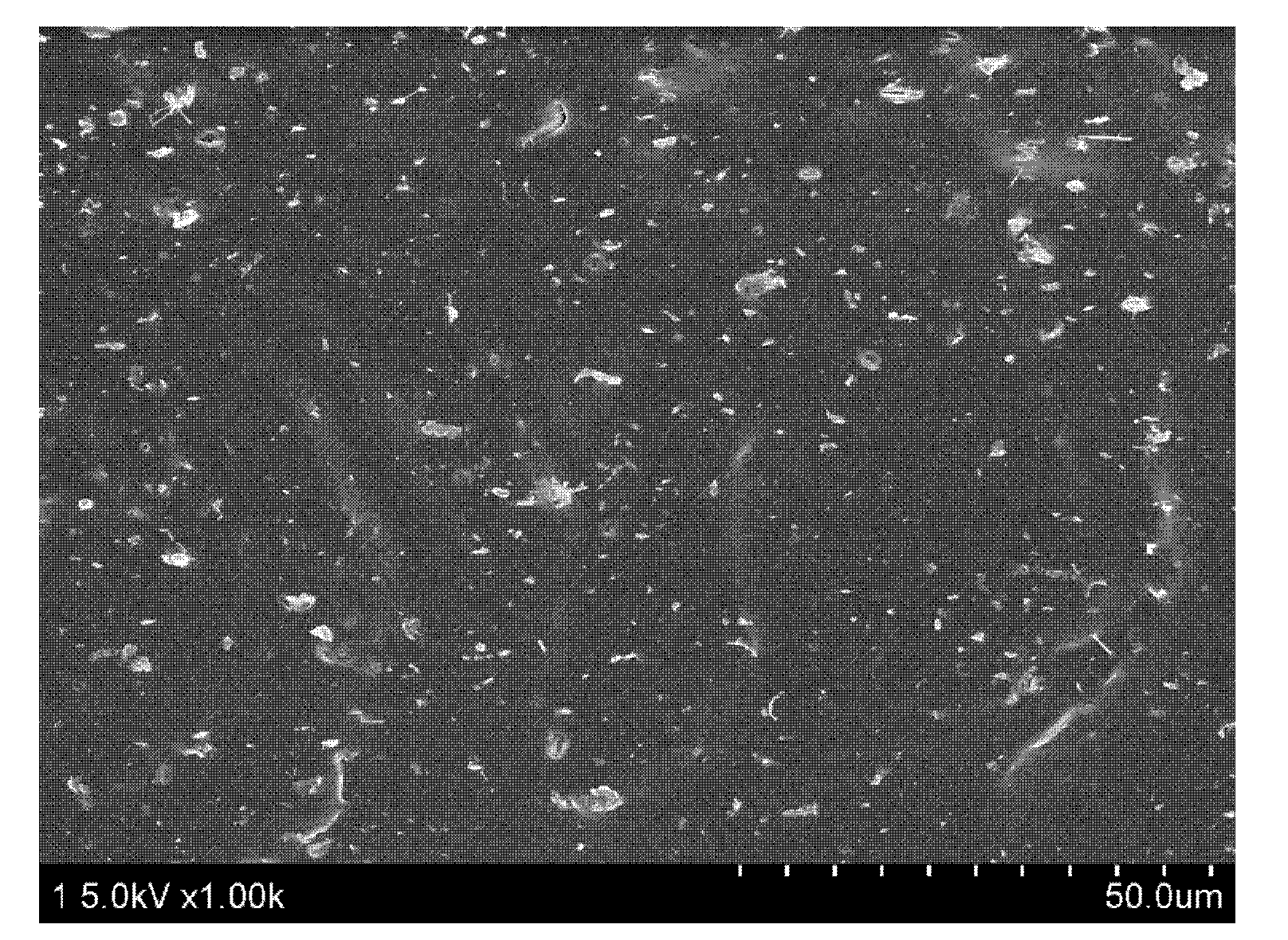

[0031] Weigh 25g of diatomaceous earth with a particle size of 300 mesh into a three-necked flask, then add 550ml of cyclohexane, 0.4g of n-propylamine and 3g of silane coupling agent KH-570, stir at room temperature for 40min at a stirring speed of 600r / min, and then Stir at 60°C for 40 min. The reacted solution was rotary evaporated at 70° C. for 1 h, then vacuum dried at 65° C. for 28 h, and diatomaceous earth was collected. Then, weigh 0.3 g of modified diatomaceous earth into a three-necked flask at room temperature, then add 110 ml of xylene, and ultrasonically disperse for 1 hour. Subsequently, 10g of TPU was added to the above solvent, the temperature was raised to 75°C, and the stirring speed was 600r / min for mechanical stirring for 5h. After the TPU is completely dissolved, the mixture is ultrasonically stirred for 1.8 h at a stirring speed of 600 r / min, and finally the solvent is evaporated at 90° C. to obtain a TPU / diatomite composite material. Field emission scan...

Embodiment 3

[0033] Weigh 30g of diatomaceous earth with a particle size of 2000 mesh into a three-necked flask, then add 700ml of cyclohexane, 0.5g of n-propylamine and 4g of silane coupling agent KH-570, stir at room temperature for 50min at a stirring speed of 650r / min, and then Stir at 60°C for 50 min. The reacted solution was rotary evaporated at 80° C. for 50 min, and then vacuum dried at 70° C. for 24 h, and diatomaceous earth was collected. Then, weigh 0.5 g of the modified diatomaceous earth into a three-necked flask at room temperature, then add 120 ml of DMF, and ultrasonically disperse for 2 hours. Subsequently, 10g of TPU was added to the above solvent, the temperature was raised to 80°C, and the stirring speed was 650r / min for mechanical stirring for 4.5h. After the TPU is completely dissolved, the mixture is ultrasonically stirred at a stirring speed of 650r / min for 1.5h, and finally the solvent is evaporated at 100°C to obtain a TPU / diatomite composite material. Field emis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com