Method for connecting target with back plate

A connection method and backplane technology, applied in welding equipment, welding equipment, laser welding equipment, etc., can solve the problems of difficult plastic deformation, high process cost, high hardness, etc., and achieve the effect of improving reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Welding of high-purity Al-0.5% Cu target and 6061Al alloy back plate

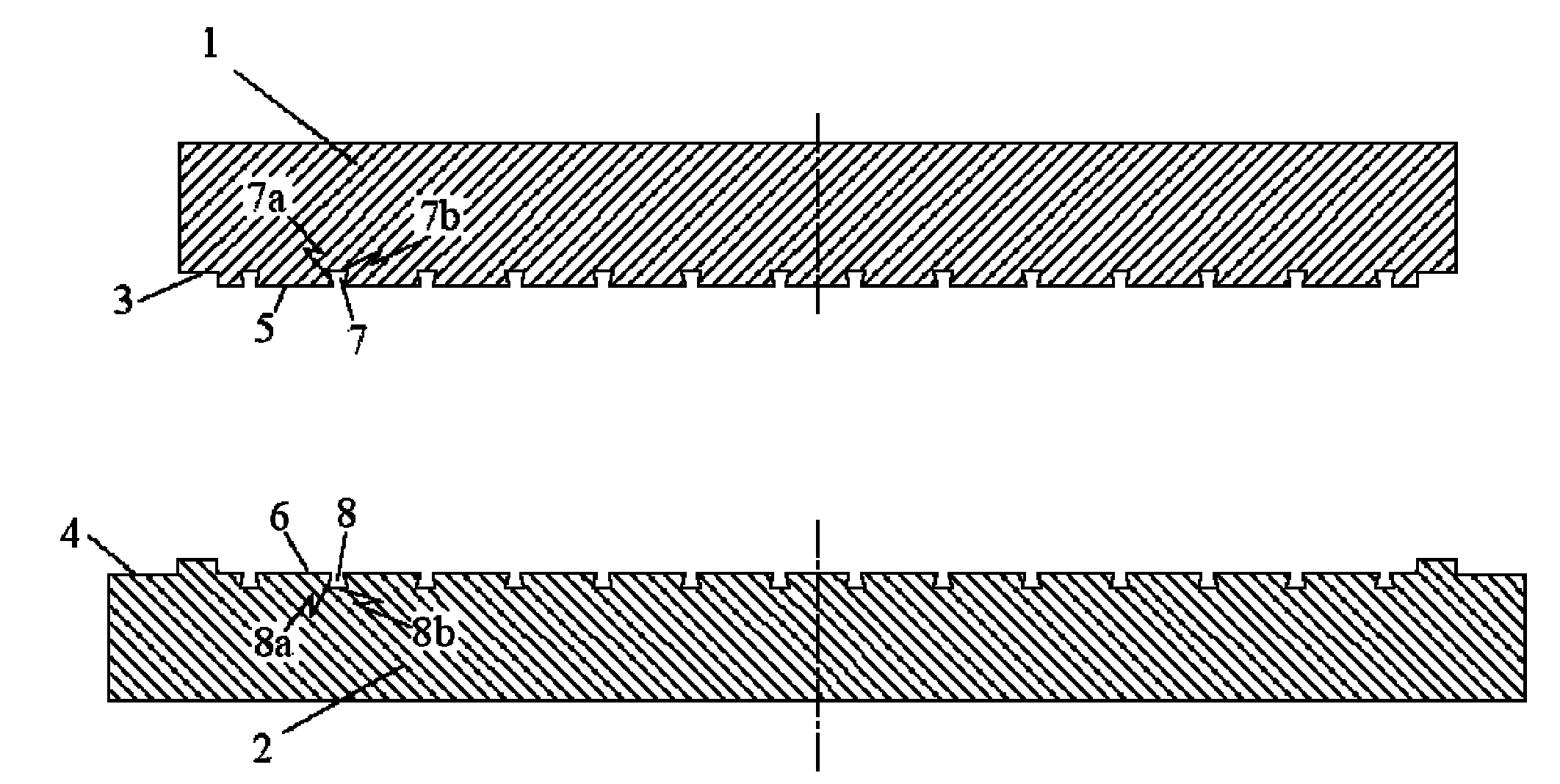

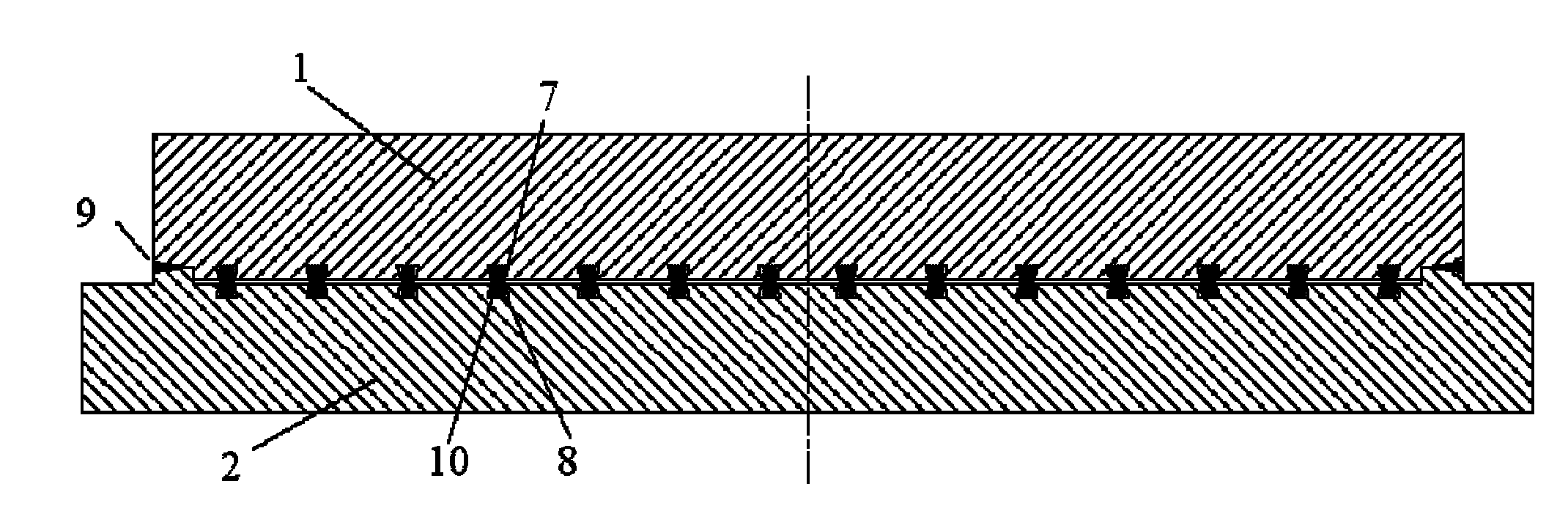

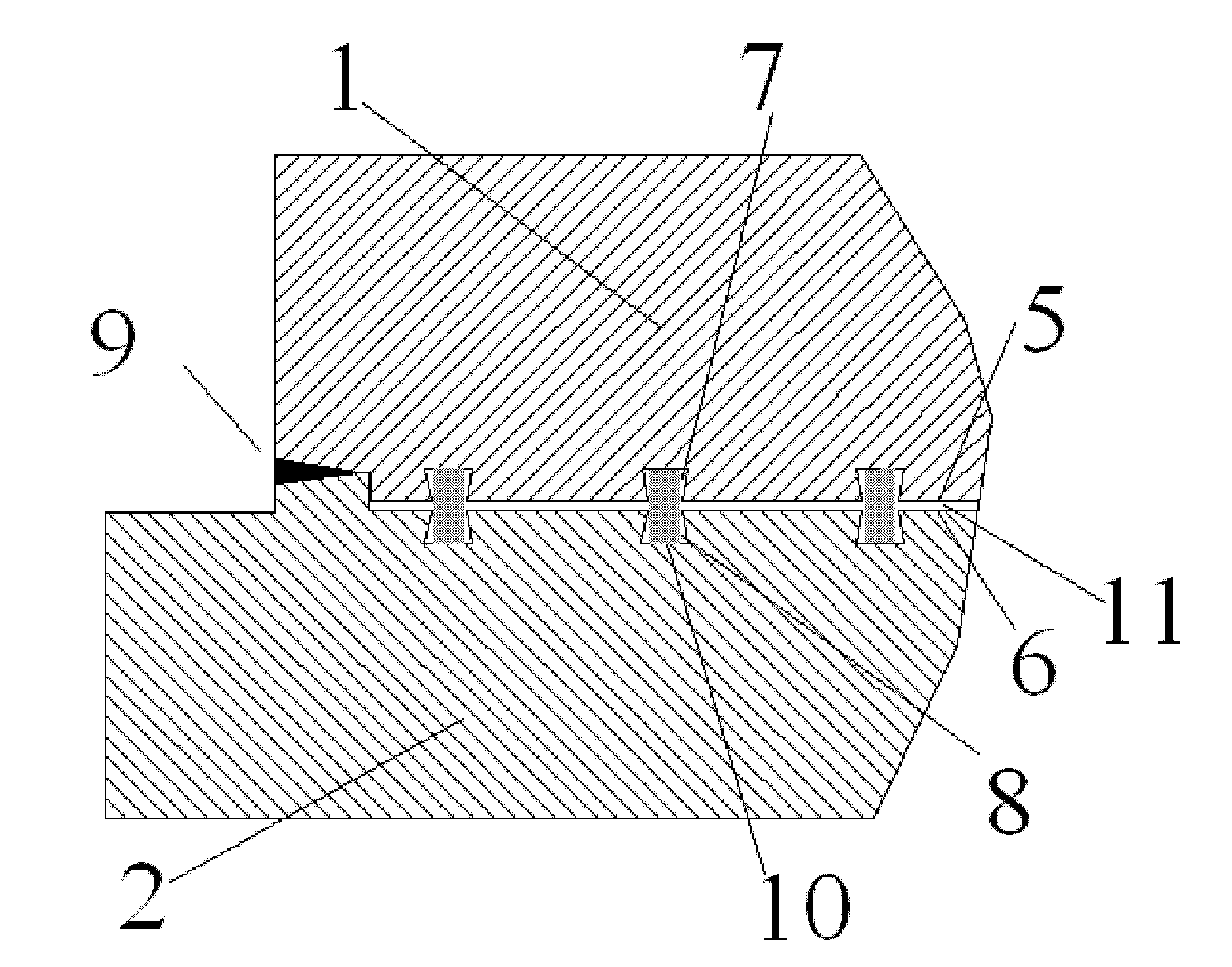

[0029] The Al-0.5% Cu disc-shaped target with a purity of 99.9995% and the surface of the 6061Al alloy disc-shaped back plate are processed figure 1 The holes shown, the hole distribution is as follows Image 6 As shown, the diameter of the hole is Ф8mm, the depth is 1.5mm, and the taper angle between the side and the bottom surface is 65°. The Vickers hardnesses of Al-0.5% Cu and 6061Al alloys are HV26 and HV105, respectively. Select Ф7.8×3.5mm pure aluminum rod as filling material, its hardness is HV23. Electron beam vacuum sealing welding is adopted, and the welding vacuum degree is >5×10 -2 Pa. like figure 2 , image 3 As shown, the depth of the welding seam 9 is 10 mm, and the gap 11 between the target material and the surfaces 5 and 6 to be welded of the back plate is 0.5 mm.

[0030] Press the sealed and welded target and back plate assembly, the reduction is >0.5mm, to ensu...

Embodiment 2

[0031] Example 2: Welding of high-purity Al-1%Si-0.5%Cu target and 6061Al alloy back plate

[0032] The Al-1%Si-0.5%Cu disk-shaped target with a purity of 99.9995% and the surface of the 6061Al alloy disk-shaped back plate are processed with grooves (sections such as figure 1 shown), the distribution of the annular groove is as follows Figure 7 As shown, the width of the groove is 6 mm, the depth is 3 mm, and the taper angle between the side and the bottom is 85°. The hardnesses of Al-0.5% Cu and 6061Al alloys are HV37 and HV105, respectively. Pure aluminum rings with a width of 5.8 mm and a height of 6.3 mm and different outer diameters are selected as filling materials, and their hardness is HV23. Electron beam vacuum sealing welding is adopted, and the welding vacuum degree is >5×10 -2 Pa. like Figure 4 As shown, the depth of the seam welding seam 12 is 4 mm, and the gap 11 between the target material and the surfaces 5 and 6 of the back plate to be welded is 0.3 mm....

Embodiment 3

[0034] Embodiment 3: Welding of high-purity Cu target material and oxygen-free copper backplane

[0035] Both the Cu-like triangular target with a purity of 99.9999% and the surface of the corresponding oxygen-free copper backplane are processed with holes. The shape of the target and the distribution of holes are as follows Figure 8 As shown, the diameter of the hole is Ф15mm, the depth is 2.0mm, and the taper angle between the side and the bottom surface is 75°. The hardness of high-purity Cu and oxygen-free copper are HV54 and HV56 respectively. An annealed pure copper rod of Ф14.5×4.8mm is selected as the filling material, and its hardness is HV45. Electron beam vacuum sealing welding is adopted, and the welding vacuum degree is >1×10 -2 Pa. like figure 2 , image 3 As shown, the depth of the welding seam 9 is 5 mm, and the gap 11 between the target material and the surfaces 5 and 6 of the back plate to be welded is about 0.8 mm.

[0036] Press the sealed and weld...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com