Device and method for removing heavy metal Pb from fly ash generated in sludge incineration

A sludge incineration and heavy metal technology, applied in the field of environmental engineering, can solve the problems of low comprehensive benefit, long process, high investment and operation costs, and achieve the effect of no secondary pollution, small amount of flue gas, and realization of recycling and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

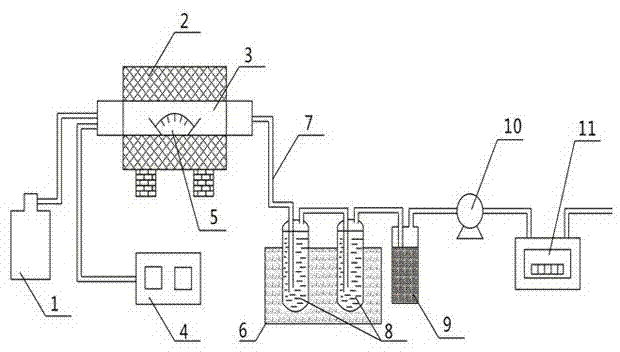

Method used

Image

Examples

Embodiment 1

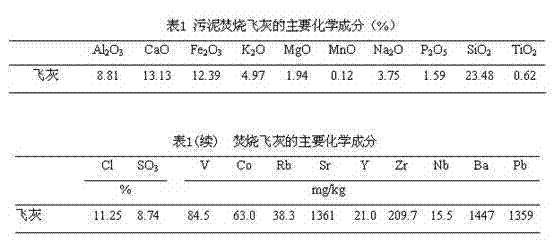

[0027] Dry 20g of fly ash at 105°C for 24 hours, then add 1.65g of chlorinating agent NaCl according to the mass ratio of fly ash to equivalent chlorinating agent of 100:5 and mix evenly. , Slowly push the porcelain boat carrying 20g of sludge incineration fly ash into the furnace, at the same time adjust the carrier gas to the set flow rate of 100mL / min, close the furnace door and start the air pump, so that the fly ash stays under this condition for 40min. Under this condition, the removal rate of Pb in fly ash is 95.4%, and the leachate content of Pb in the residual fly ash after treatment is lower than the standard value of Pb for the toxicity identification of leachate from hazardous waste (GB5085-1996).

Embodiment 2

[0029] Dry 20g of fly ash at 105°C for 24 hours, then add 1.65g of chlorinating agent NaCl according to the mass ratio of fly ash to equivalent chlorinating agent of 100:5 and mix evenly. , Slowly push the porcelain boat carrying 20g of sludge incineration fly ash into the furnace, at the same time adjust the carrier gas to the set flow rate of 100mL / min, close the furnace door and start the air pump, so that the fly ash stays under this condition for 60min. Under this condition, the removal rate of Pb in the fly ash is 98.6%, and the leachate content of Pb in the residual fly ash after treatment is lower than the standard value of Pb for the toxicity identification of the leachate of hazardous waste (GB5085-1996).

Embodiment 3

[0031] Dry 50g of fly ash at 105°C for 24h, then add 7.82g of chlorinating agent CaCl according to the mass ratio of fly ash to equivalent chlorinating agent of 100:10 2 Mix evenly. When the hearth of the high-temperature atmosphere tube-type electric furnace reaches the preset temperature of 1000°C, slowly push the porcelain boat carrying 50g of sludge incineration fly ash into the furnace, and at the same time adjust the carrier gas to the set flow rate of 100mL / min and close the furnace Open the door and start the suction pump to make the fly ash stay under this condition for 40 minutes. Under this condition, the removal rate of Pb in fly ash is 95.1%, and the leachate content of Pb in the residual fly ash after treatment is lower than the standard value of Pb for the toxicity identification of leachate from hazardous waste (GB5085-1996).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com