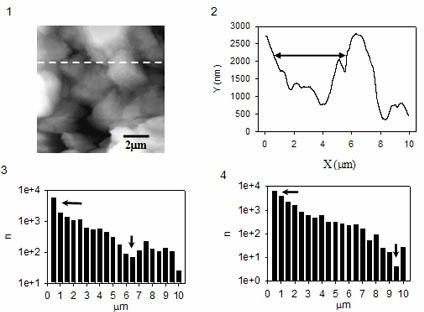

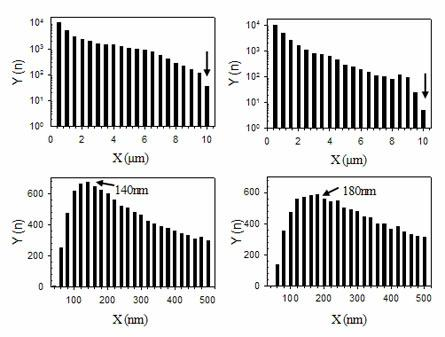

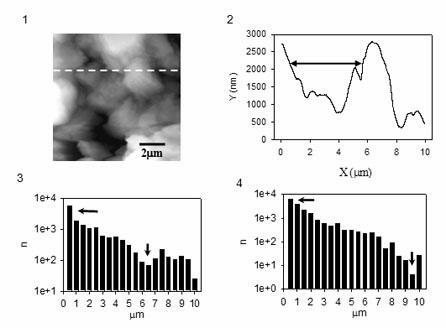

Characterization method of atomic force microscope for micro-pore structure of reservoir rock core

An atomic force microscope and micro-pore technology, applied in the field of oil and gas fields, can solve the problems of inaccuracy, accurate determination of the micro-pore structure error of the reservoir rock, damage to the core structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific examples.

[0015] Firstly, cores were taken industrially at 1138.0 meters from Well Xing2-1-Jian29 in the main oil producing area of Daqing Oilfield, and the rock samples were processed into a cylindrical shape with a diameter of 1 inch on the core bank bench drill, and then core processing equipment was used along the diameter Saw it into thin slices with a thickness of no more than 3 mm, then simply clean the attached dust with an ordinary soft brush and leave it for observation with an atomic force microscope. The actual observed rock samples are core slices with a diameter of 1 inch and a thickness of 3 mm. Note that the surface of the core slices cannot undergo any chemical treatment to ensure the original state of the rock samples. The second is to transform the atomic force microscope to make it suitable for the characterization of the microscopic pore structure of the reservoir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com