Compact flat-plate solid oxide direct carbon fuel cell stack

A solid oxide, fuel cell stack technology, used in solid electrolyte fuel cells, fuel cells, fuel cell additives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

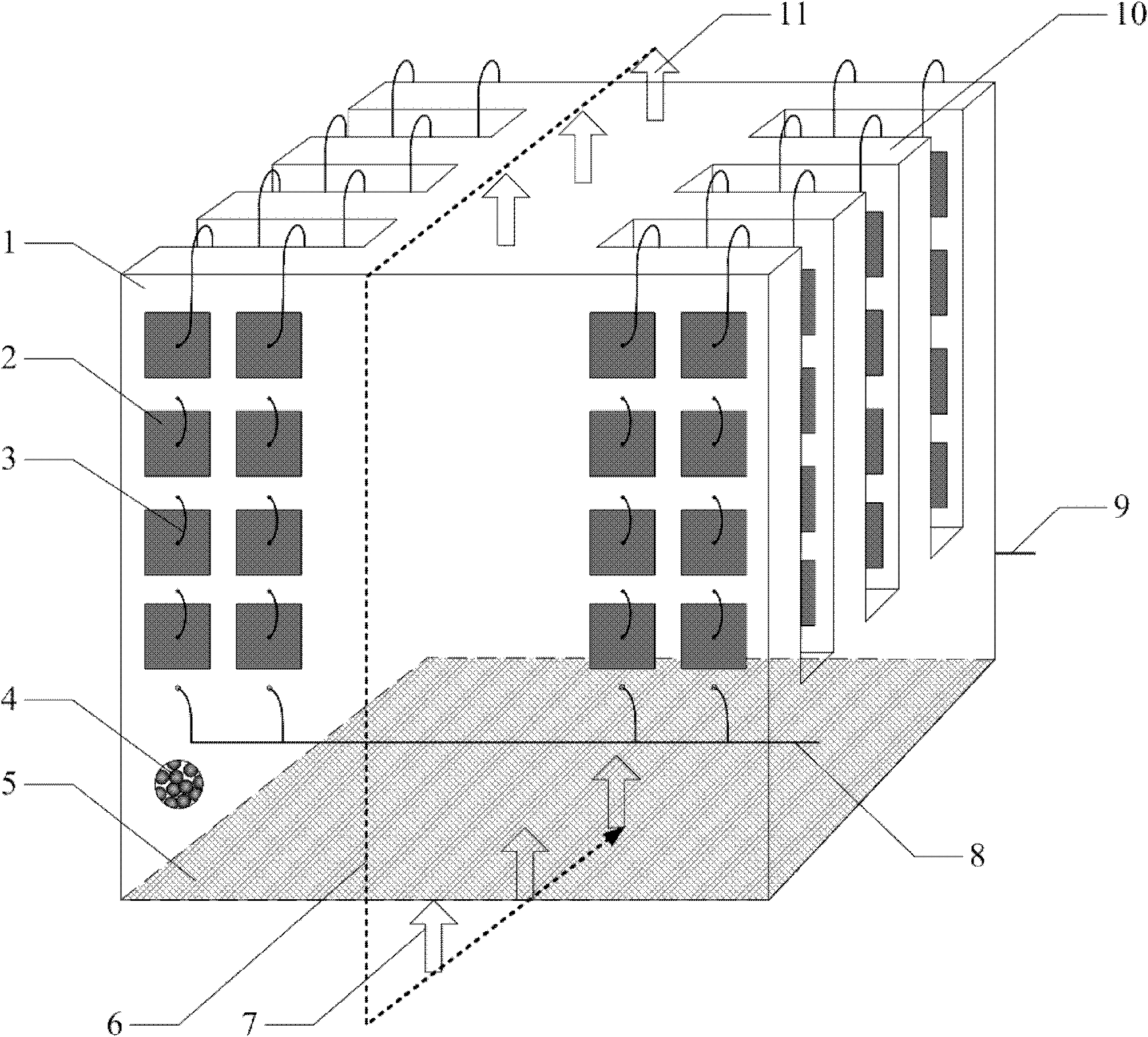

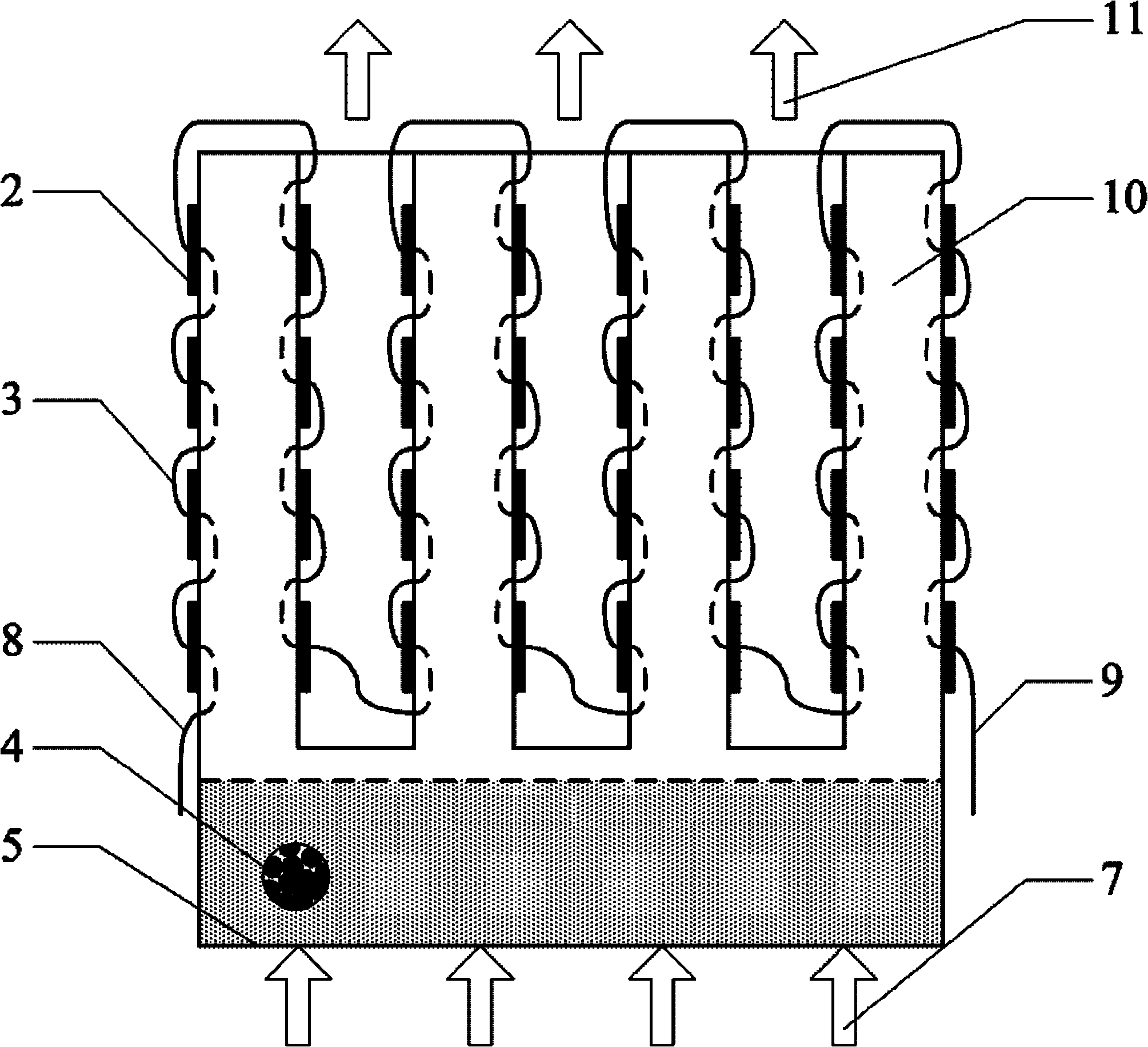

[0037] A compact planar solid oxide direct carbon fuel cell stack consisting of 128 anode-supported solid oxide fuel cell cells with a cell size of 10cm×10cm; graphite with a particle size of 5mm to 50μm is used as solid carbon fuel ; The anode carrier gas component is pure CO 2 After the reaction, 70% of the anode carrier gas is exported for recycling; the working temperature of the battery stack is 800°C.

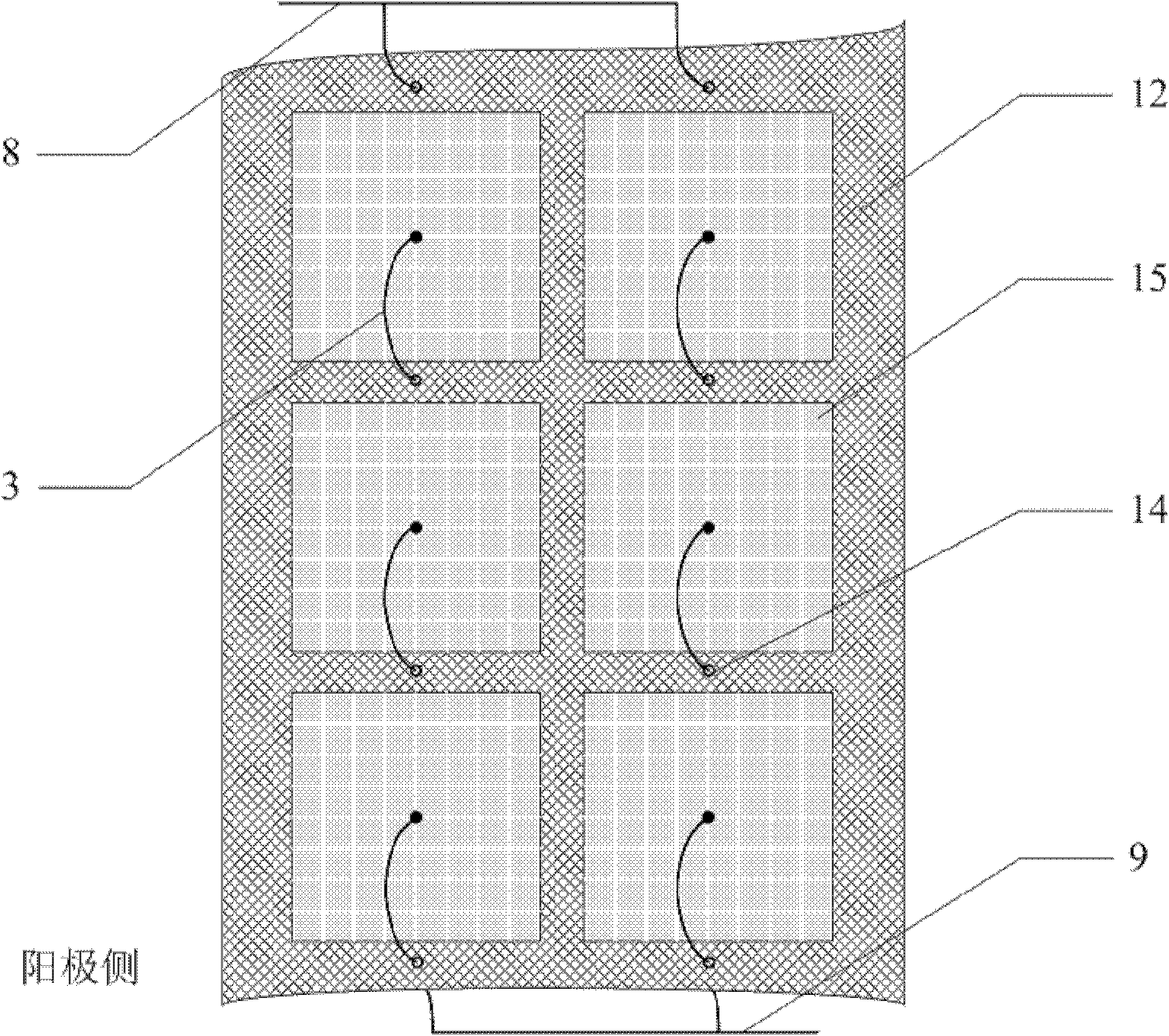

[0038] Both sides of the middle and upper part of the bubbling bed are composed of 4 plate fins, which provide a larger installation area of flat fuel cell cells on the basis of ensuring the sealing of the bubbling bed. There are 2×4 (horizontal×vertical) rectangular holes of about 10cm×10cm on both side walls of each plate fin, and the anode-supporting fuel cell monomers are respectively installed at the openings on the wall surface of the plate fin. Anode-supported planar fuel cells such as Figure 6 As shown, the battery cell is composed of an anode 15 , an electro...

Embodiment 2

[0041] A compact planar solid oxide direct carbon fuel cell stack consisting of 144 electrolyte-supported solid oxide fuel cell cells with a cell size of 8cm×8cm; carbon black with a particle size of 5mm to 100μm is used as solid carbon Fuel; anode carrier gas composition is 70% CO 2 +30%H 2 O, 50% of the anode carrier gas exported after the reaction is used for recycling; the working temperature of the battery stack is 900°C.

[0042] Both sides of the upper and middle parts of the bubbling bed are composed of 6 plate fins, which provide a larger installation area for flat fuel cell cells on the basis of ensuring the sealing of the bubbling bed. There are 2×3 (horizontal×vertical) rectangular holes of about 8cm×8cm on both side walls of each plate fin, and the electrolyte-supported fuel cell monomers are respectively installed at the openings on the wall surface of the plate fin. Electrolyte-supported planar fuel cells such as Figure 7 As shown, the battery cell is compos...

Embodiment 3

[0045] A compact planar solid oxide direct carbon fuel cell stack consisting of 384 cathode-supported solid oxide fuel cell cells with a cell size of 9cm×9cm; coal with a particle size of 5mm to 200μm is used as solid carbon fuel ; Anode carrier gas composition is 50% CO 2 +30%H 2 O+20%N 2 , after the reaction, the outlet anode carrier gas is directly evacuated; the working temperature of the cell stack is 1000°C.

[0046] Both sides of the middle and upper part of the bubbling bed are composed of 8 plate fins, which provide a larger installation area of flat fuel cell cells on the basis of ensuring the sealing of the bubbling bed. There are 3×4 (horizontal×vertical) rectangular holes of about 9cm×9cm on both side walls of each plate fin, and the cathode-supported fuel cell monomers are respectively installed at the openings on the wall surface of the plate fin. A cathode-supported planar fuel cell such as Figure 8As shown, the battery cell is composed of an anode 15 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com