Dental composite resin material with low polymerization shrinkage rate

A composite resin, shrinkage technology, applied in dentistry, dental preparations, dental prostheses, etc., can solve the problems of low polymerization shrinkage and polymerization stress, poor compatibility of adhesives, and inability to exceed overall performance.

Inactive Publication Date: 2011-09-21

吉林省登泰克牙科材料有限公司

View PDF4 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to many problems such as high water absorption value, toxicity, and poor compatibility with other adhesives, this type of system has not been industrialized.

[0010] 3M has developed a class of epoxy resin monomers, which have lower polymerization shrinkage and polymerization stress, and have been proven to be feasible, but the overall performance still cannot exceed the usual methacrylate composite resin

And require a very high conversion rate, otherwise the performance of the product is poor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0064] Tetrahydrofurfuryl Acrylate 40%, Bisphenol A Diglycidyl Dimethacrylate 59%, Initiator 1%

Embodiment 2

[0066] Macromonomer I 30%, tetrahydrofurfuryl acrylate 20%, bisphenol A diglycidyl dimethacrylate 49%, initiator 1%.

Embodiment 3

[0068] Macromonomer I 50%, tetrahydrofurfuryl acrylate 20%, bisphenol A diglycidyl dimethacrylate 29%, initiator 1%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Login to View More

Abstract

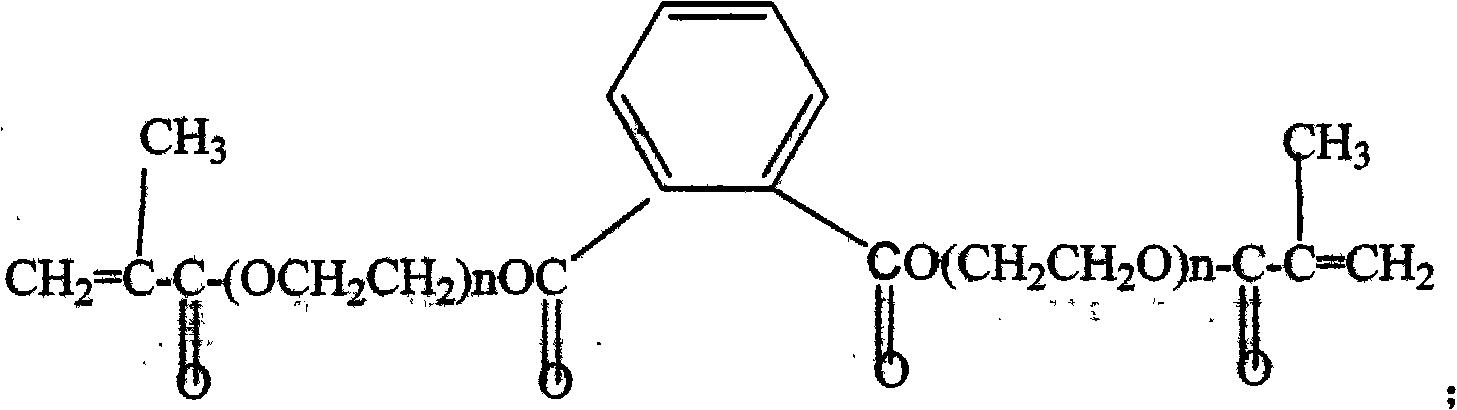

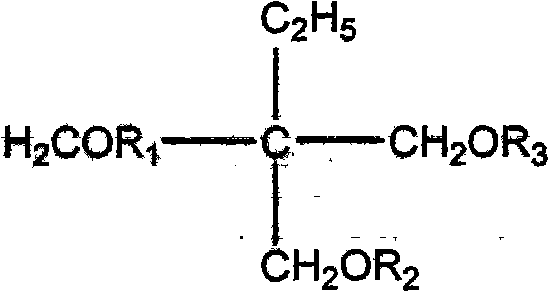

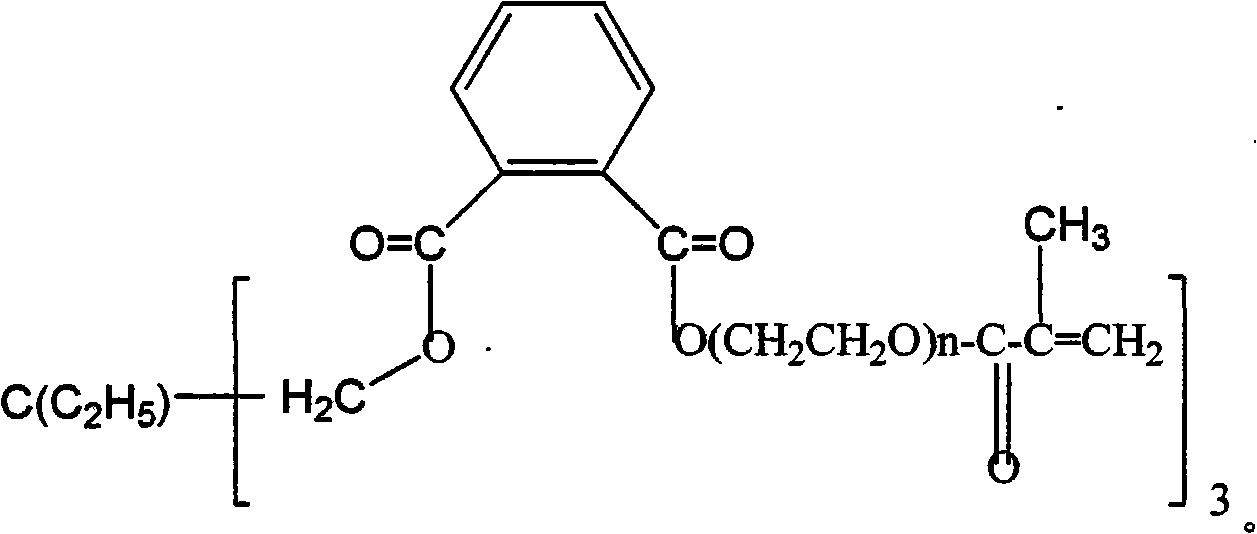

The invention relates to a dental composite resin material with a low polymerization shrinkage rate, which belongs to the technical field of composite resin materials for repairing or remaking tooth. The dental composite resin material is formed in a mode that a composite resin monomer mixture is mixed with inorganic filler. The composite resin monomer mixture consists of a macro monomer, an acrylate monomer with a vinyl as an end group, an acrylate monomer containing two double bonds and an initiator. The macro monomer is an aromatic polyester low polymer with two or three double bonds. In the invention, the macro monomer is added into the composite resin material; and the macro monomer has the characteristics of low viscosity, high molecular weight and the like, so that the using amount of the inorganic filler can be increased and the polymerization shrinkage rate can be reduced, and thus, the edge micro leakage caused by volume shrinkage in the polymerization process of the materials is reduced and the occurrence probability of secondary caries is reduced.

Description

Technical field: [0001] The invention relates to a composite resin material containing a macromolecular monomer and having a low polymerization shrinkage rate for tooth restoration or reconstruction. Background technique: [0002] The composite material made of resin and inorganic filler is not only similar to real teeth in terms of strength, hardness, wear resistance, polishing, color, etc., but also can be endowed with fluorine release function and photochromic diagnostic function, which is similar to real teeth. Various functions such as light transmission and scattering properties are increasingly widely used in tooth repair and reconstruction. It is foreseeable that due to the comprehensive advantages in aesthetics and performance, resin composite materials will completely replace traditional inorganic and metal materials. [0003] There is an Achilles' heel in the resin composite material itself, that is, the volume shrinkage of the material during polymerization and t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A61K6/087A61K6/027A61K6/891

Inventor 闫刚马荣堂

Owner 吉林省登泰克牙科材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com