Storable emulsified asphalt cold-patch mixture and preparation method and application thereof

A technology of emulsified asphalt and cold-replenishing material, applied in the direction of roads, road repair, roads, etc., can solve the problems of adverse effects on the strength and durability of the mixture, slow volatilization, etc., to improve the efficiency of road maintenance, enhance the consistency, overcome the formation strength slow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

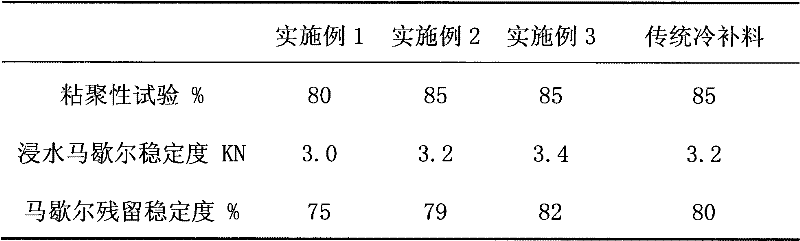

[0039] The preparation method of the emulsified asphalt cold patch in this embodiment is as follows. Take 1% polyester fiber, 1% emulsion method polyoxyethylene, and the rest of the stone in the mixer and mix for 1 to 2 minutes, then add 6% water, stir for 0.5 to 1 minute, fully wet the stone, and then add 7% part of emulsified asphalt, after stirring for 1 minute, sealed and bagged to obtain emulsified asphalt cold patch. Wherein the composition weight ratio of each component of the emulsified asphalt is: No. 70 asphalt balance, GYM-02 emulsifier 1% (Henan Province Weisende Road Material Co., Ltd.), cellulose sodium 1%, water 26.5 parts. When in use, take out the cold patch material, pour it into the pit, and after compaction, it can be opened for traffic. The performance indicators are shown in Table 1.

Embodiment 2

[0041] The preparation method of the emulsified asphalt cold patch in this embodiment is as follows. Take 2% lignin fiber, 3% fumed silica, and the rest of the stone and mix it in a mixer for 1-2 minutes, then add 5% water, stir for 0.5-1 minute, fully wet the stone, and then add 10 % emulsified asphalt, after stirring for 1 minute, sealed and bagged to obtain emulsified asphalt cold patch. Wherein the composition weight ratio of each component of the emulsified asphalt is: No. 70 asphalt balance, UCAN-58 emulsifier 1.26% (phenol ether sulfate, Shanghai Zhongcheng Fine Chemical Co., Ltd.), sodium polyacrylate 1.08%, water 29.16%. When in use, take out the cold patch material, pour it into the pit, and after compaction, it can be opened for traffic. The performance indicators are shown in Table 1.

Embodiment 3

[0043] The preparation method of the emulsified asphalt cold patch in this embodiment is as follows. Take 1% lignin fiber, 2% fumed silica, and the rest of the stone and mix them in a mixer for 1-2 minutes, then add 5.5% water, stir for 0.5-1 minute, fully wet the stone, and then add 8 % parts of emulsified asphalt, after stirring for 1 minute, sealed and bagged to obtain emulsified asphalt cold patch. Wherein the composition weight ratio of each component of the emulsified asphalt is: the remainder of No. 70 asphalt, 1.5% of UCAN-58 emulsifier (phenol ether sulfate, Shanghai Zhongcheng Fine Chemical Co., Ltd.), 2% of sodium cellulose, and 30.32% of water. When in use, take out the cold patch material, pour it into the pit, and after compaction, it can be opened for traffic. The performance indicators are shown in Table 1.

[0044] Table 1 Performance indicators of emulsified asphalt cold patch

[0045]

[0046] The cohesion test performance of the emulsified asphalt col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| residual stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com