Phosphor and preparation method

A technology of phosphors and compounds, applied in the field of luminescent materials, can solve the problems of orange luminous color and low color purity, and achieve the effects of high color purity, low light decay, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The composition of embodiment 1 is Gd 1.95 Eu 0.05 P 4 o 13 red phosphor

[0033] Weigh gadolinium oxide Gd 2 o 3 0.7069g, europium oxide Eu2 o 3 0.0176g and diammonium hydrogen phosphate (NH 4 ) 2 HPO 4 1.3734g (the quality of diammonium hydrogen phosphate is according to Gd 1.95 Eu 0.05 P 4 o 13 The molar equivalent of the P element in the element is calculated by 30% excess, and the calculation methods in the following examples are all the same as this example). Put the above raw materials into an agate mortar and thoroughly grind them, put them into a corundum crucible and pre-sinter them at 300°C for 5 hours, then cool them down to room temperature naturally, take them out and grind them thoroughly again. Finally, the reground product was calcined at 1000°C for 8 hours, cooled to room temperature naturally, and white powder Gd was obtained after taking out and grinding 1.95 Eu 0.05 P 4 o 13 of red phosphor.

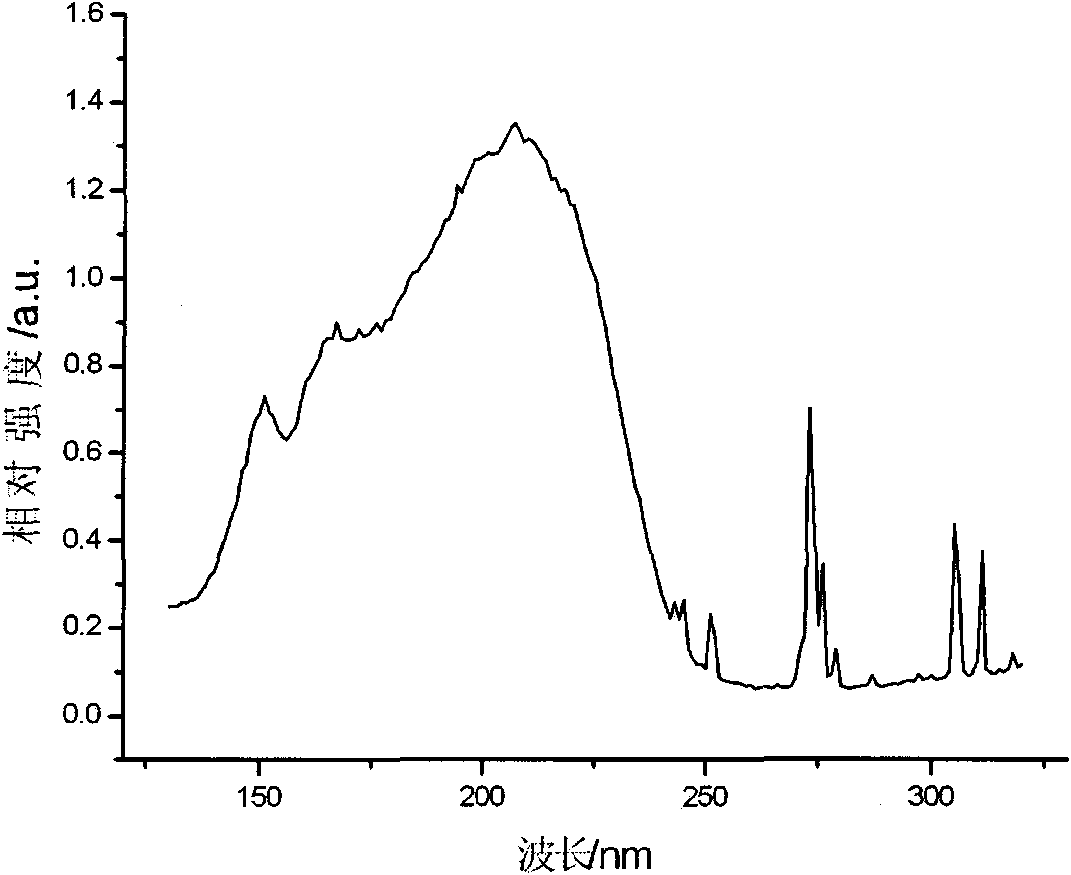

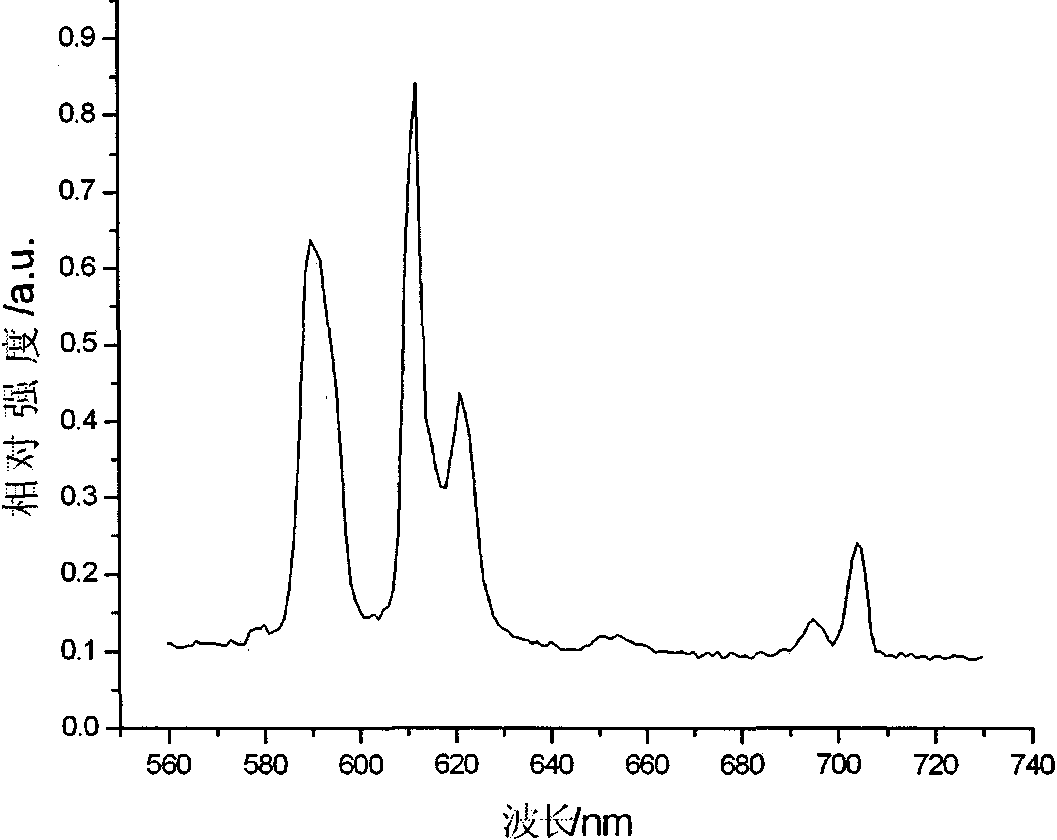

[0034] figure 1 is the Gd of Examp...

Embodiment 2

[0035] The composition of embodiment 2 is Y 1.95 Eu 0.05 P 4 o 13 red phosphor

[0036] Weigh yttrium oxide Y 2 o 3 0.4403g, europium oxide Eu 2 o 3 0.0176g and diammonium hydrogen phosphate (NH 4 ) 2 HPO 4 1.3734 g (30% excess). Put the above raw materials into an agate mortar and thoroughly grind them, put them into a corundum crucible and pre-sinter them at 300°C for 5 hours, then cool them down to room temperature naturally, take them out and grind them thoroughly again. Finally, the reground product was calcined at 1050°C for 8 hours, cooled to room temperature naturally, and white powder Y was obtained after taking out and grinding. 1.95 Eu 0.05 P 4 o 13 red phosphor.

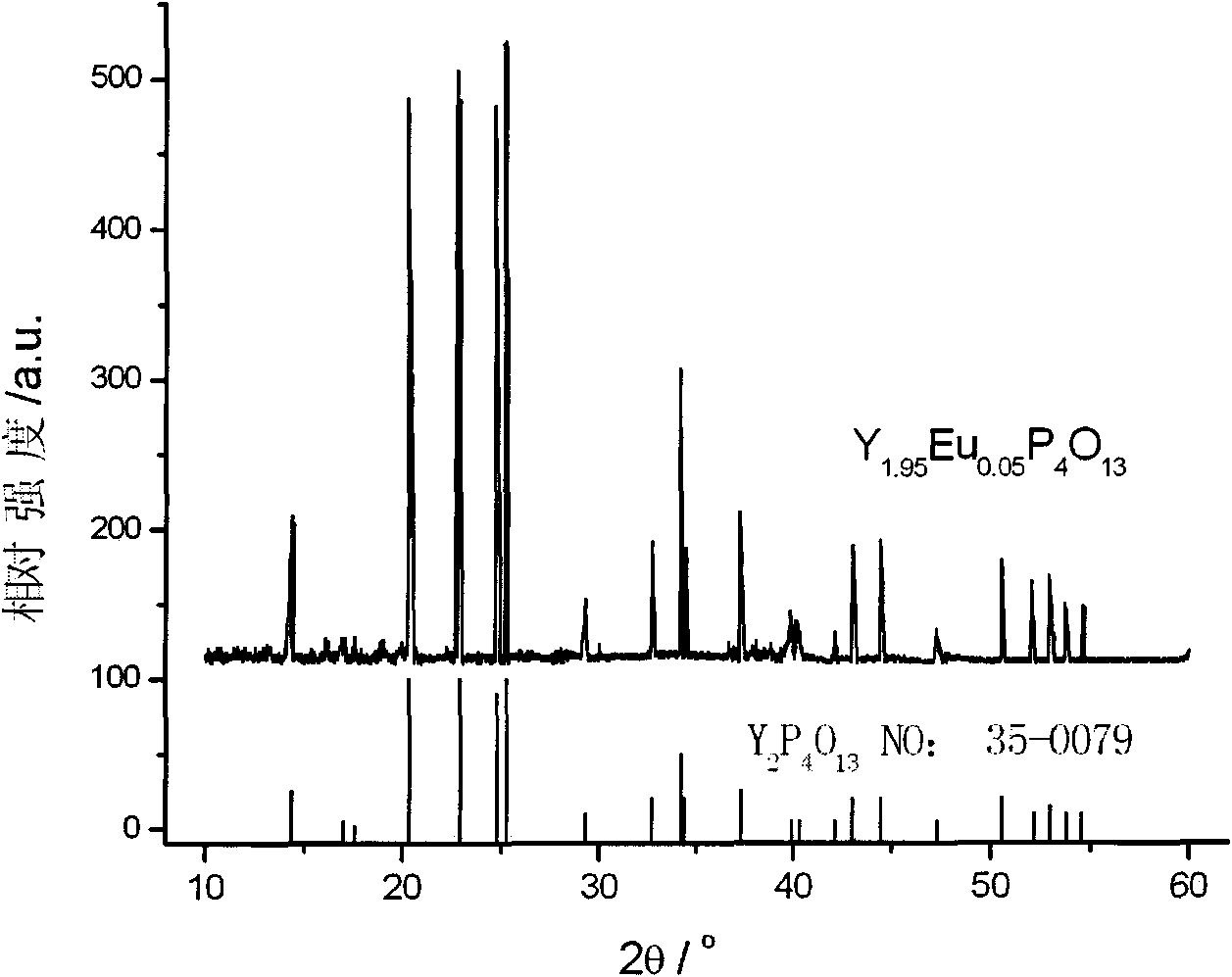

[0037] image 3 is Y of Example 2 of the present invention 1.95 Eu 0.05 P 4 o 13 X-ray diffraction pattern (XRD) and Y of red phosphor powder 2 P 4 o 13 Comparison chart of standard card NO: 35-0079. According to the rules of crystallization chemistry, ions with similar ionic ra...

Embodiment 3

[0039] The composition of embodiment 3 is La 1.95 Eu 0.05 P 4 o 13 red phosphor

[0040] Weigh lanthanum oxide La 2 o 3 0.6353g, europium oxide Eu 2 o 3 0.0176g and diammonium hydrogen phosphate (NH 4 ) 2 HPO 4 1.3734 g (30% excess). Put the above raw materials into an agate mortar and thoroughly grind them, put them into a corundum crucible and pre-sinter them at 300°C for 5 hours, then cool them down to room temperature naturally, take them out and grind them thoroughly again. Finally, the re-ground product was calcined at 1050°C for 8 hours, cooled to room temperature naturally, taken out and ground to obtain a white powder La 1.95 Eu 0.05 P 4 o 13 red phosphor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com