Nanometer carbon fiber vacuum superconducting heat pipe and manufacturing method thereof

A nano-carbon fiber, super heat-conducting tube technology, applied in tubular elements, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of decreased heat transfer efficiency, easy corrosion of tube walls, easy fatigue of heat pipes, etc., and achieves fast heat transfer speed. , good temperature uniformity, the effect of a wide range of applicable temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

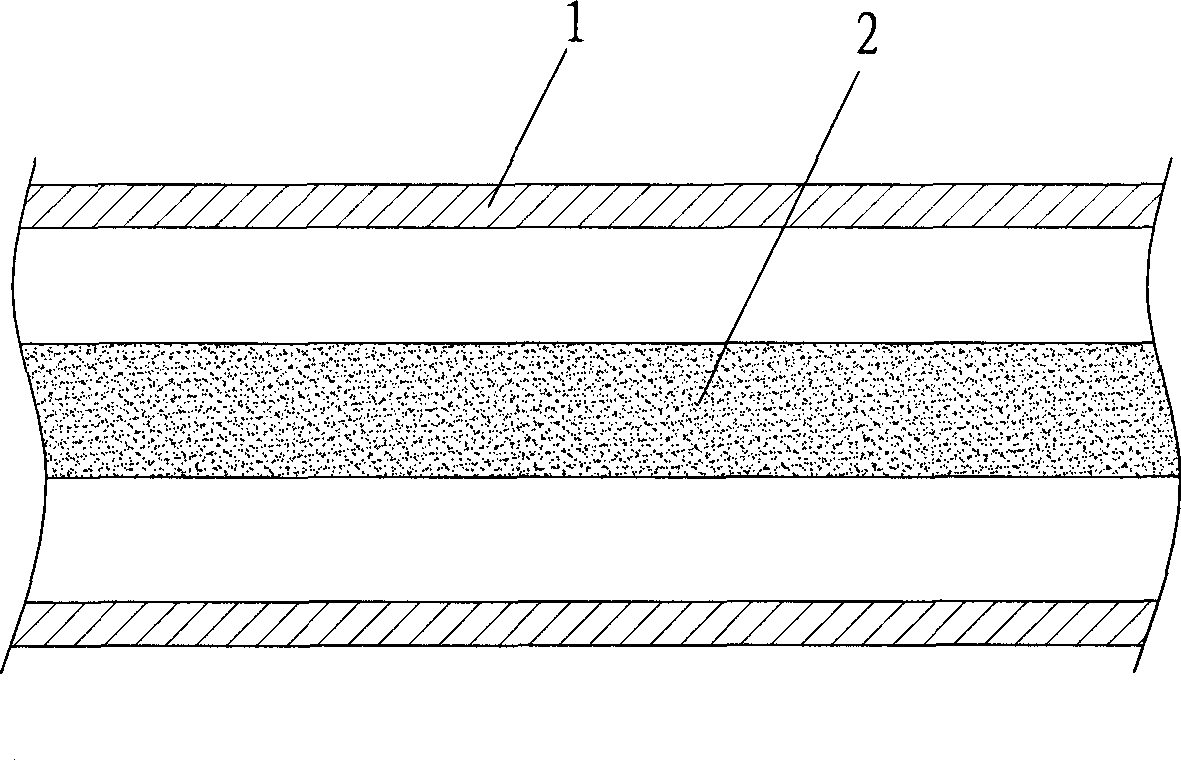

[0042] Such as figure 1 As shown, a carbon nanofiber vacuum superconducting heat pipe disclosed by the present invention includes a vacuum tube 1 and a superconducting medium 2 made of carbon nanofibers.

[0043] Among them, the vacuum tube 1 is formed by sealing the tube shell and the end cap, and can be made of copper, carbon steel, stainless steel and other metals or non-metallic tubular or plate materials such as glass and ceramics; the superconducting medium 2 is a mixture of nano-carbon fibers. The superconducting medium 2 is injected into the vacuum tube 1, and after sealing and forming, a high-efficiency heat pipe is formed.

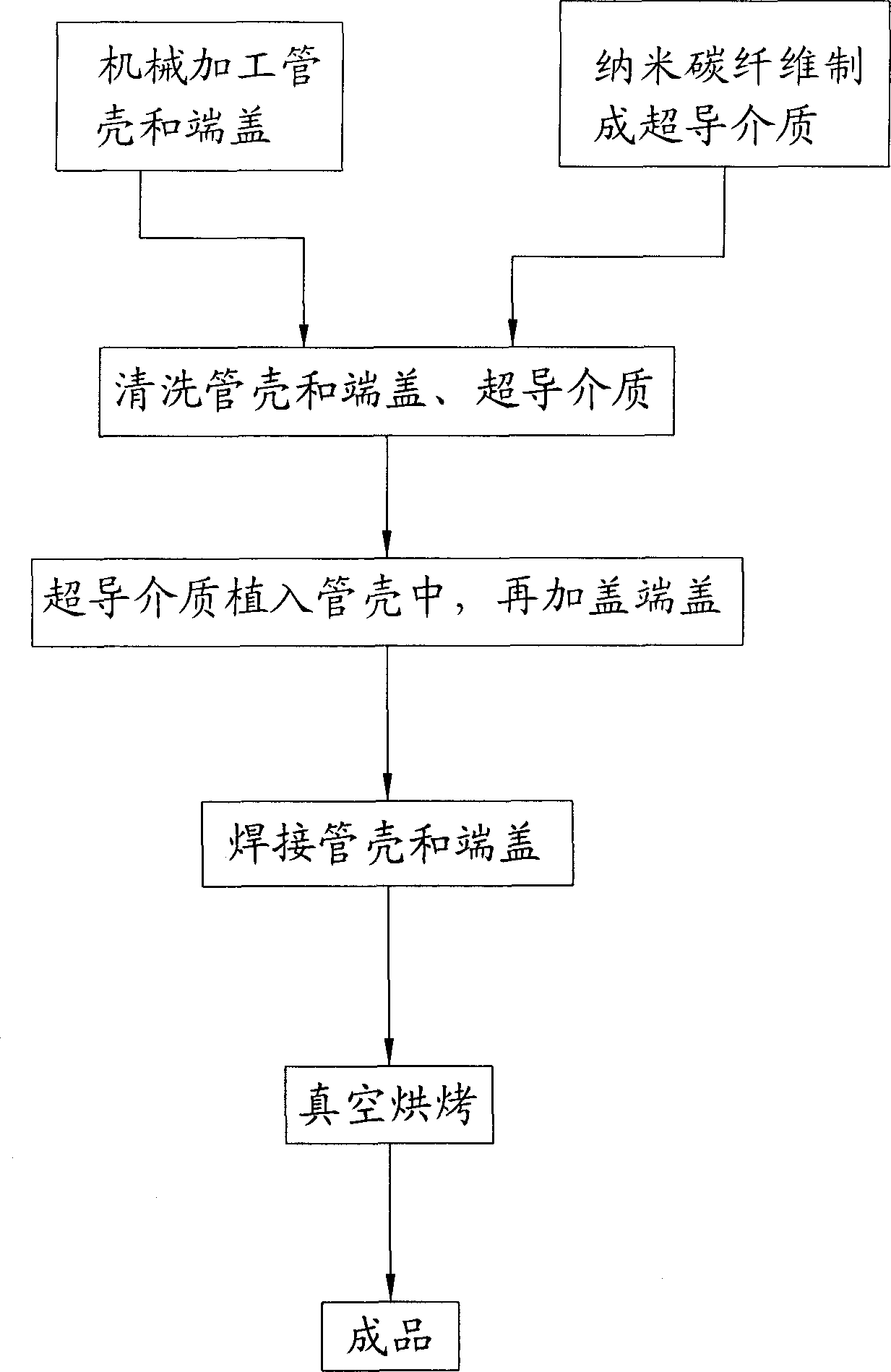

[0044] The specific processing of the superconducting heat pipe, such as figure 2 As shown, the shell and end cap of the vacuum tube are made by machining first. The selection of the shell material should pay attention to the characteristics of thermal conductivity, vacuum maintenance, pressure resistance, fluid compatibility (corrosion, chemic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com