Open microstructured fiber for having composite fiber core and using shifted single-hole diversion

A microstructured optical fiber, an open technology, applied in the directions of cladding optical fiber, optical waveguide light guide, light guide, etc., which can solve the problem of poor optical field-substance overlap of polished total internal reflection microstructured fiber and poor optical fiber diversion characteristics. , complex processing, low yield and other problems, to achieve excellent real-time sensing performance, improve real-time effect, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

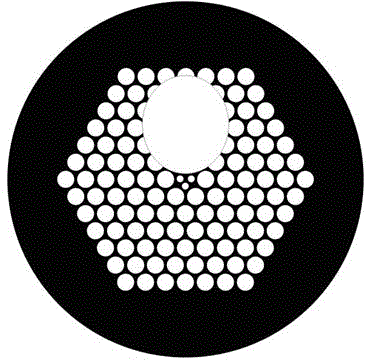

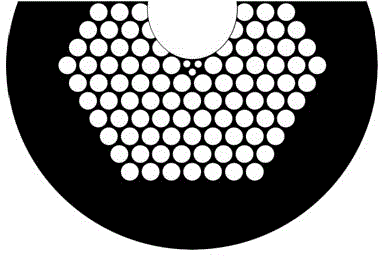

[0025] In the preparation of a kind of composite fiber core partial single-hole diversion open microstructure optical fiber provided by the present invention, the stacking method or ultrasonic drilling method is used to generate the preform rod, and then the same process as ordinary microstructure optical fiber drawing can be used to complete one-time molding , the preparation material can choose quartz glass or polymer material, after molding, such as figure 1 As shown, where the black filled part represents the base material, while the white part is air. Its structure includes a core and a cladding. The cladding except the guide hole is consistent with the ordinary photonic crystal fiber. It is a periodic arrangement of air holes surrounding the core, and the aperture is on the order of wavelength. Every three air hole units form an equilateral triangle, and the overall bandgap structure is an equilateral hexagon. For the design of the air holes in the cladding, the equilat...

Embodiment 2

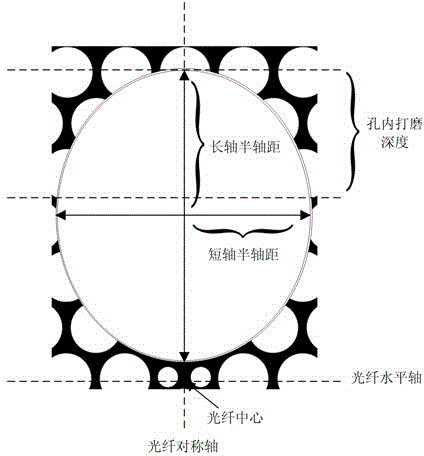

[0031] This embodiment provides another kind of composite fiber core with non-uniform size air holes in the fiber core region with single-hole guide open microstructure optical fiber. The base material of the fiber is quartz glass, and the two sides of the inverted triangle top edge An air hole is located 0.9 microns above the horizontal axis of the fiber, 1.3 microns away from the fiber's symmetry axis, and has a radius of 0.6 microns. The air hole at the apex of the inverted triangle is located 0.4 microns directly below the center point of the fiber, and its radius is 1.15 microns. The guide holes are the same as in Example 1. The air holes 2 in the cladding are uniformly arranged in the base material according to the equilateral triangle rule generally adopted by ordinary photonic crystal fibers known in the art, and the radius of each air hole is d=1 micron, and the hole distance=2.25 microns.

[0032] The distribution ratio of the detection light field in the measured s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com