A photonic crystal fiber

A photonic crystal fiber and fiber technology, applied in glass fiber, cladding fiber, optical waveguide light guide, etc., can solve the problems of polarization mode dispersion, effective refractive index difference, inter-mode coupling or crosstalk, etc., to achieve low dispersion, nonlinear The effect of small coefficient and low limit loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the following embodiments illustrate a photonic crystal fiber of the present invention in detail with reference to the accompanying drawings.

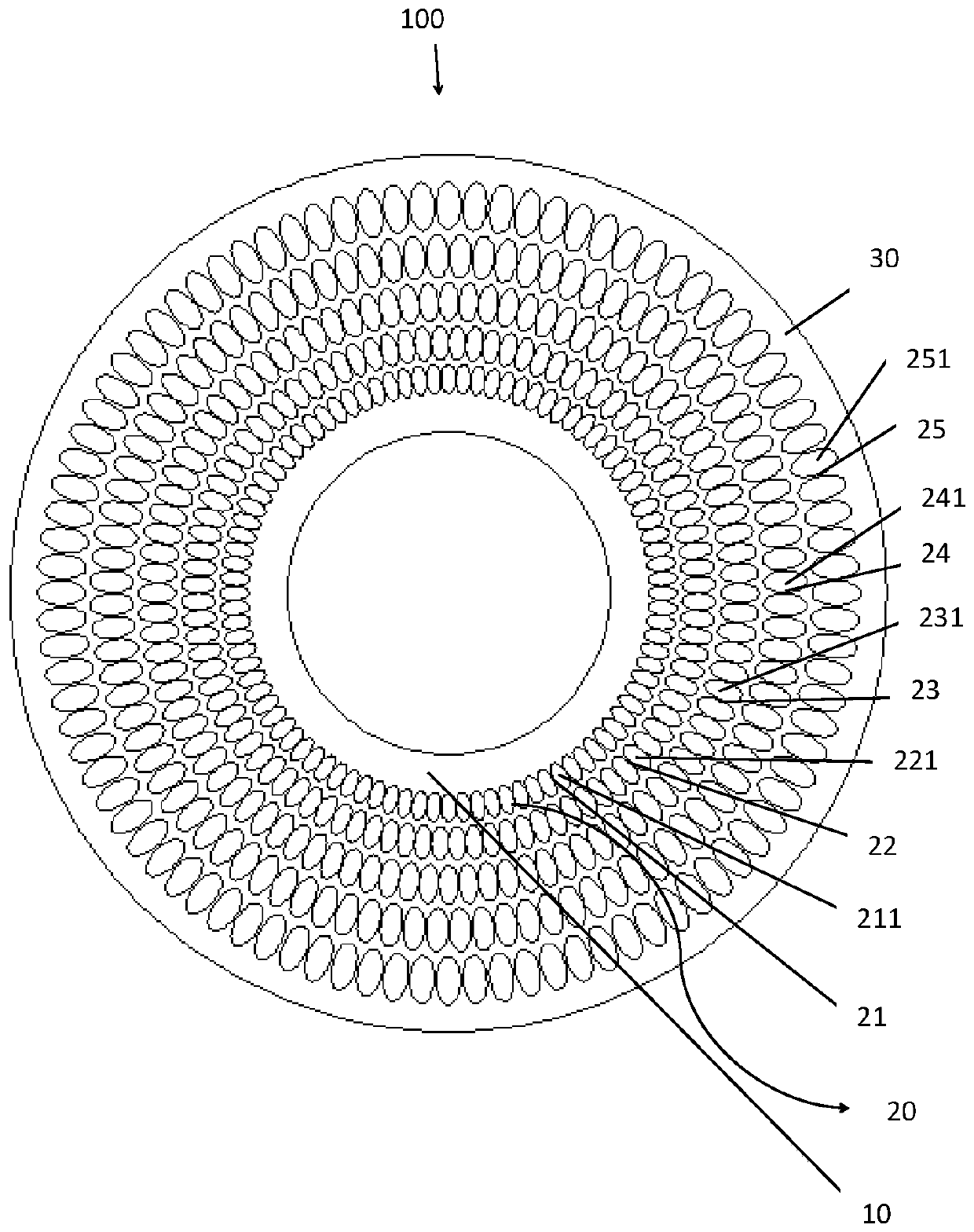

[0025] figure 1 It is a schematic diagram of the cross-sectional structure of a photonic crystal fiber of the present invention.

[0026] The shape of photonic crystal fiber is long and linear. The cross-sectional structure of photonic crystal fiber is as figure 1 As shown, the photonic crystal fiber 100 includes a core layer 10 , a cladding layer 20 and a coating layer 30 from inside to outside. And the core layer 10 , the cladding layer 20 and the coating layer 30 are all concentric.

[0027] The core layer 10 is located in the inner ring of the cross-sectional structure of the photonic crystal fiber 100 . The center of the core layer 10 has a circular hole, the radius of the circular hole is in the range...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com